Toyota RAV4 (XA40) 2013-2018 Service Manual: Active test

Hint:

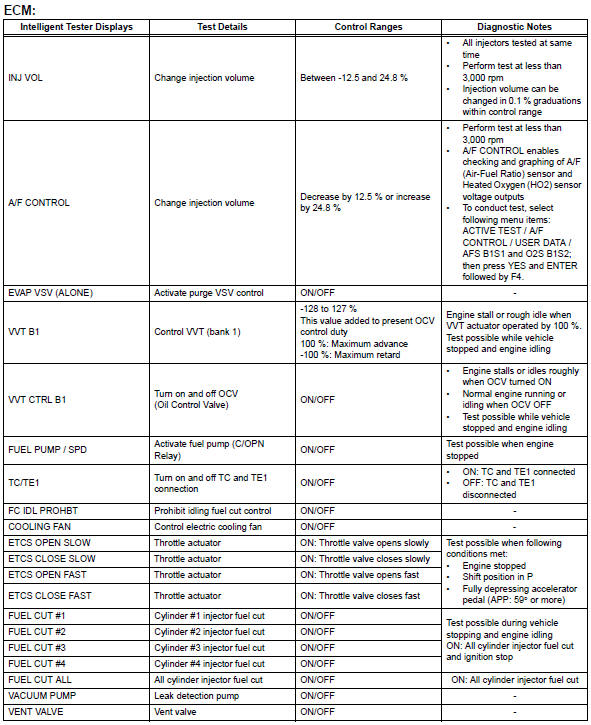

Performing an active test enables components including the relays, vsv (vacuum switching valve) and actuators, to be operated without removing any parts.

The active test can be performed with the intelligent tester. Performing the active test as the first step of troubleshooting is one method of shortening diagnostic time.

Data list can be displayed during active test.

- Connect the intelligent tester to the dlc3.

- Turn the ignition switch on.

- Turn the tester on.

- Select the following menu items: diagnosis / enhanced obd ii / active test.

- Perform the active test by referring to the table below.

Hint:

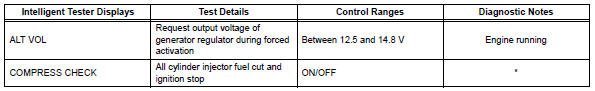

*: When cranking the engine, each cylinder measures the engine rpm.

In this active test, the fuel and ignition of all cylinders is cut, and cranking occurs for approximately 10 seconds. Then, each cylinder measures the engine rpm. If a cylinder's engine rpm is higher than the others, that cylinder's compression pressure is compared to the others, and whether or not the compression pressure is low can be determined.

- Warm up the engine.

- Turn the ignition switch off.

- Connect the intelligent tester to the dlc3.

- Turn the ignition switch on and turn the intelligent tester on.

- Select the following menu items: diagnosis / enhanced obd ii / active test / compress check.

Hint:

If the results are not displayed normally, select the display items from the data list before performing the active test. Select the following menu items: diagnosis / enhanced obd ii / data list / user data / eng speed #1 and eng speed #2, eng speed #3, eng speed #4 (press the yes button to change the eng speed #1 to #4 is yes) and then press the enter button.

- While the engine is not running, press the right or left button to change the compress check to on.

Hint:

After performing the above procedure, the active test's compress check will start. Fuel injection for all cylinders is prohibited, and the each cylinder's engine rpm measurement will enter standby.

- Fully open the throttle.

- Crank the engine for about 10 seconds.

- Monitor the engine speed (eng speed #1 to #4) displayed on the tester.

Hint:

At first, the tester's display will show each cylinder's engine rpm measurement to be extremely high. After approximately 10 seconds of engine cranking, each cylinder's engine rpm measurement will change to the actual engine rpm.

Notice:

- After the active test's compress check is turned on, it will automatically turn off after 255 seconds.

- When the compress check test is off and the engine is cranked, the engine will start.

- If the compress check test needs to be performed after it is turned on and performed once, press exit to return to the active test menu screen. Then perform the compress check test again.

- Use a fully-charged battery.

Data list

Data list

Hint:

By reading the data list displayed on an intelligent

tester, values can be checked, including those of the

switches, sensors, and actuators, without removing any

parts. Reading the data list ...

System check

System check

Hint:

Performing a system check enables the system,

which consists of multiple actuators, to be operated

without removing any parts. In addition, it can show

whether or not any dtcs are set, and c ...

Other materials:

Back door outside garnish

Components

Removal

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

Remove back door center garnish (see page

ed-5 ...

Windshield wiper de-icer

This feature is used to prevent ice from building up on the windshield

and wiper blades.

On/off

The windshield wiper de-icer will

automatically turn off after approximately

15 minutes. Pressing the

switch again also turns the de-icer

off.

Operating conditions

Vehicles without a smart ...

Ecm / pcm internal engine off timer performance

Dtc summary

Description

To ensure the accuracy of the evap (evaporative emission) monitor values, the

soak timer, which is built

into the ecm, measures 5 hours (+-15 minutes) from when the ignition switch is

turned off, before the

monitor is run. This allows the fuel to cool down, wh ...