Toyota RAV4 (XA40) 2013-2018 Service Manual: Camshaft position "a" actuator circuit (bank 1)

Dtc

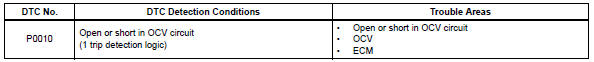

P0010 Camshaft position "a" actuator circuit (bank 1)

Description

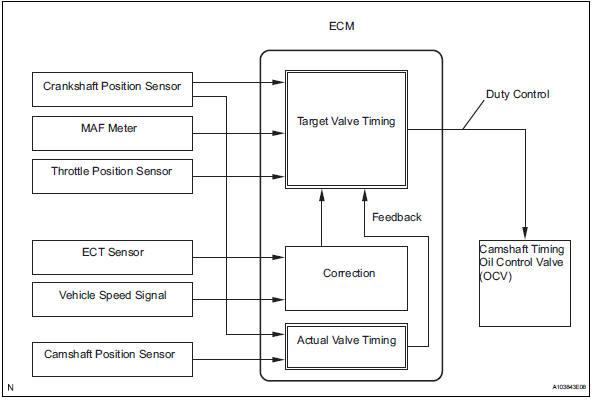

The variable valve timing (vvt) system includes the ecm, ocv and vvt controller. The ecm sends a target duty-cycle control signal to the ocv. This control signal regulates the oil pressure supplied to the vvt controller. Camshaft timing control is performed according to engine operating conditions such as the intake air volume, throttle valve position and engine coolant temperature. The ecm controls the ocv, based on the signals transmitted by several sensors. The vvt controller regulates the intake camshaft angle using oil pressure through the ocv. As a result, the relative positions of the camshaft and crankshaft are optimized, the engine torque and fuel economy improve, and the exhaust emissions decrease under overall driving conditions. The ecm detects the actual intake valve timing using signals from the camshaft and crankshaft position sensors, and performs feedback control. This is how the target intake valve timing is verified by the ecm.

Hint:

This dtc relates to the oil control valve (ocv).

Monitor description

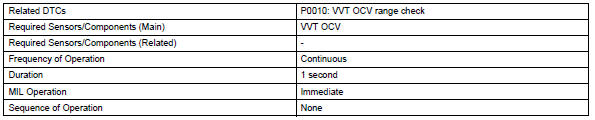

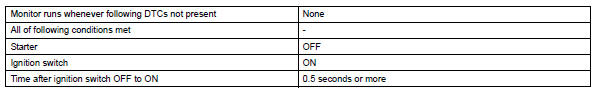

The ecm optimizes the valve timing using the vvt system to control the intake camshaft. The vvt system includes the ecm, the ocv and the vvt controller. The ecm sends a target duty-cycle control signal to the ocv. This control signal regulates the oil pressure supplied to the vvt controller. The vvt controller can advance or retard the intake camshaft.

After the ecm sends the target duty-cycle control signal to the ocv, the ecm monitors the ocv current to establish an actual duty-cycle. The ecm determines the existence of a malfunction and sets the dtc when the actual duty-cycle ratio varies from the target duty-cycle ratio.

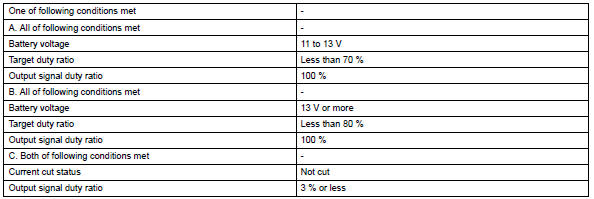

Monitor strategy

Typical enabling conditions

Typical malfunction thresholds

Component operating range

![]()

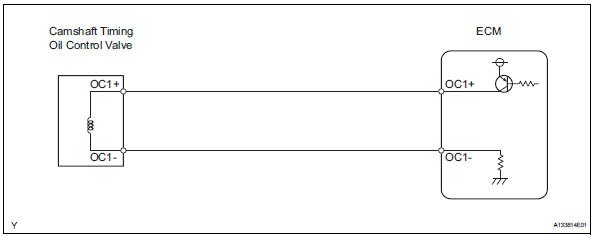

Wiring diagram

Inspection procedure

Hint:

Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

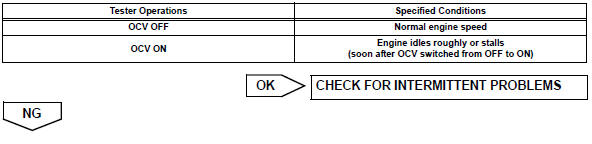

- Perform active test using intelligent tester (operate ocv)

- Connect the intelligent tester to the dlc3.

- Start the engine and turn the tester on.

- Warm up the engine.

- On the tester, select the following menu items: diagnosis / enhanced obd ii / active test / vvt ctrl b1.

- Check the engine speed while operating the oil control valve (ocv) using the tester.

Ok

- Inspect camshaft timing oil control valve assembly

- Disconnect the b17 ocv connector.

- Measure the resistance between the terminals of the ocv.

Standard resistance: 6.9 To 7.9 ٠at 20°c (68°f)

- Reconnect the ocv connector.

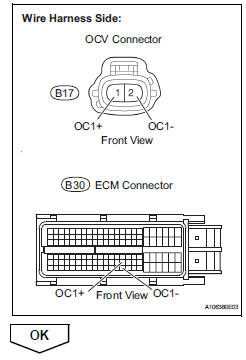

- Check harness and connector (ocv - ecm)

- Disconnect the b17 ocv connector.

- Disconnect the b30 ecm connector.

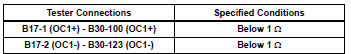

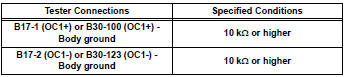

- Measure the resistance of the wire harness side connectors.

Standard resistance (check for open)

Standard resistance (check for short)

- Reconnect the ocv connector.

- Reconnect the ecm connector.

Diagnostic trouble code chart

Diagnostic trouble code chart

Hint:

Parameters listed in the chart may be different than your

readings depending on the type of instrument and other

factors.

If any dtcs are displayed during a check mode dtc check,

check th ...

Camshaft position "A"

Camshaft position "A"

Dtc P0011 Camshaft position

"a" - timing over-advanced or system performance (bank 1)

Dtc P0012 Camshaft

position "a" - timing over-retarded (bank 1)

Description

The v ...

Other materials:

Installation (2005/11-2006/01)

Install no. 1 Roof silencer pad

W/o sliding roof:

Install the 5 silencer pads.

W/ sliding roof:

Install the 2 silencer pads.

Install no. 3 Roof silencer pad

Install no. 1 Roof wire

Only when replacing the roof headlining:

Align the marking, and then ...

The keys

The following keys are provided with the vehicle.

Vehicles without a smart key system (type a)

Master keys

Operating the wireless remote control

function

Valet key

Key number plate

Vehicles without a smart key system (type b)

Master keys

Operating the wireless r ...

Sensor detection display,

object distance

â– Detection range of the sensors

Approximately 3.3 ft. (100

cm)

Approximately 4.9 ft. (150

cm)

Approximately 2.1 ft. (63 cm)

The diagram shows the detection

range of the sensors. Note that the

sensors cannot detect objects that are extremely close to the vehicle.

The range of the sensors ...