Toyota RAV4 (XA40) 2013-2018 Service Manual: Evaporative emission control system incorrect purge flow

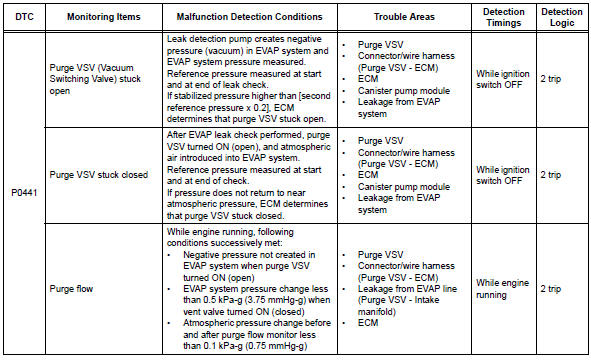

Dtc summary

Description

The description can be found in the evap (evaporative emission) system (see page es-335).

Inspection procedure

Refer to the evap system (see page es-340).

Monitor description

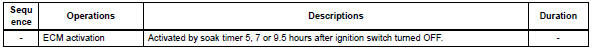

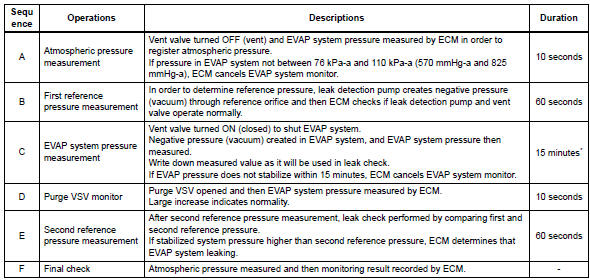

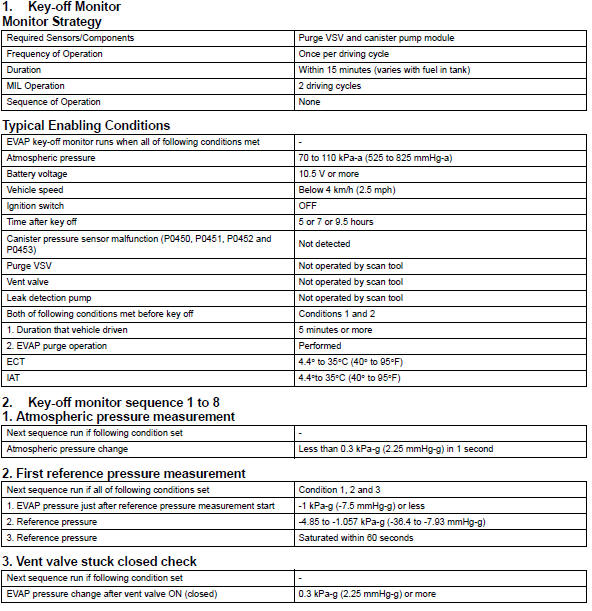

The two monitors, key-off and purge flow, are used to detect malfunctions relating to dtc p0441. The key-off monitor is initiated by the ecm internal timer, known as the soak timer, 5 hours* after the ignition switch is turned off. The purge flow monitor runs while the engine is running.

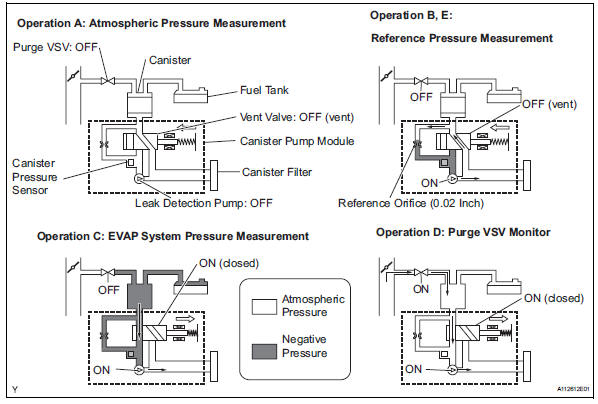

- Key-off monitor

5 Hours* after the ignition switch is turned off, the leak detection pump creates negative pressure (vacuum) in the evap system. The ecm monitors for leaks and actuator malfunctions based on the evap pressure.

Hint:

*: If the engine coolant temperature is not below 35°c (95°f) 5 hours after the ignition switch is turned off, the monitor check starts 2 hours later. If it is still not below 35°c (95°f) 7 hours after the ignition switch is turned off, the monitor check starts 2.5 Hours later.

*: If only a small amount of fuel is in the fuel tank, it takes longer for the evap pressure to stabilize.

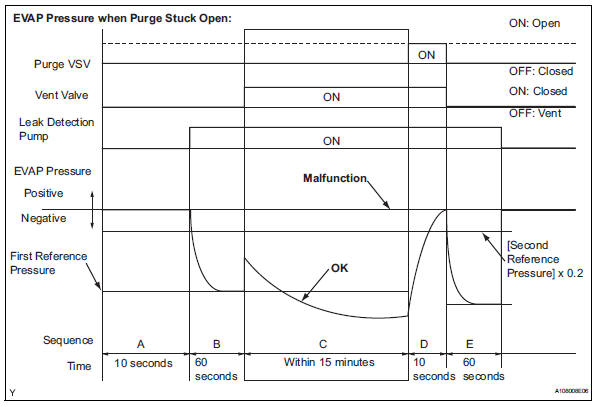

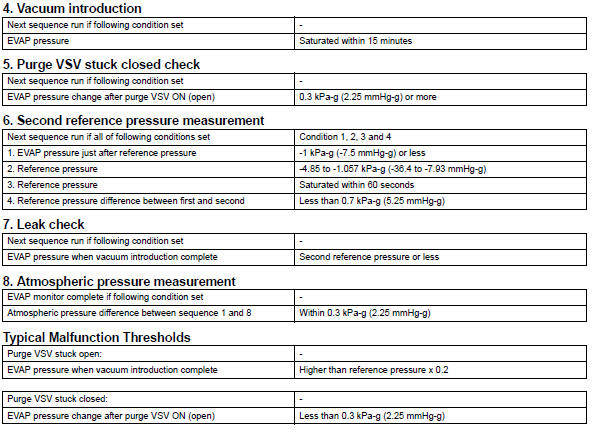

- Purge vsv stuck open

In operation c, the leak detection pump creates negative pressure (vacuum) in the evap system.

The evap system pressure is then measured by the ecm using the canister pressure sensor. If the stabilized system pressure is higher than [second reference pressure x 0.2], The ecm interprets this as the purge vsv (vacuum switching valve) being stuck open. The ecm illuminates the mil and sets the dtc (2 trip detection logic).

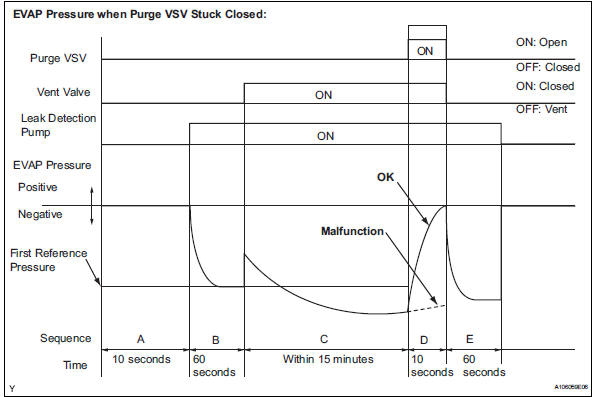

- Purge vsv stuck closed

In operation d, the canister pressure sensor measures the evap system pressure. The pressure measurement for purge vsv monitor is begun when the purge vsv is turned on (open) after the evap leak check. When the measured pressure indicates an increase of 0.3 Kpa-g (2.25 Mmhg-g) or more, the purge vsv is functioning normally. If the pressure does not increase, the ecm interprets this as the purge vsv being stuck closed. The ecm illuminates the mil and sets the dtc (2 trip detection logic).

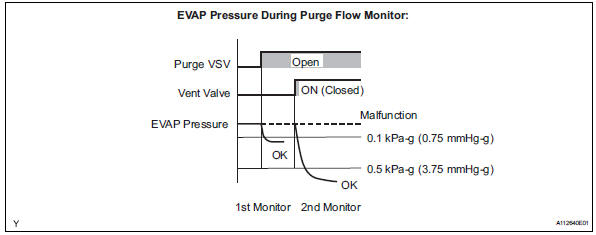

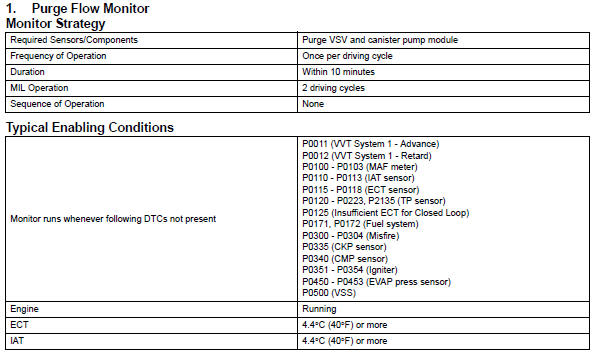

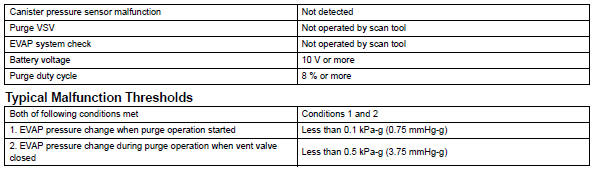

- Purge flow monitor

The purge flow monitor consists of the two step monitors. The 1st monitor is conducted every time and the 2nd monitor is activated if necessary.

- The 1st monitor

While the engine is running and the purge vsv is on (open), the ecm monitors the purge flow by measuring the evap pressure change. If negative pressure is not created, the ecm begins the 2nd monitor.

- The 2nd monitor

The vent valve is turned on (closed) and the evap pressure is then measured. If the variation in the pressure is less than 0.5 Kpa-g (3.75 Mmhg-g), the ecm interprets this as the purge vsv being stuck closed, and illuminates the mil and sets dtc p0441 (2 trip detection logic).

Atmospheric pressure check: in order to ensure reliable malfunction detection, the variation between the atmospheric pressures, before and after conduction of the purge flow monitor, is measured by the ecm.

Obd ii monitor specifications

Obd ii monitor specifications

Monitor result

Refer to checking monitor status (see page es-17).

Evaporative emission system reference orifice

Evaporative emission system reference orifice

Dtc summary

Hint:

The reference orifice is located inside the canister pump module.

Description

The description can be found in the evap (evaporative emission) system (see

page es-335).

...

Evaporative emission control system pressure sensor

Evaporative emission control system pressure sensor

Dtc summary

Hint:

The canister pressure sensor is built into the canister pump module.

Description

The description can be found in the evap (evaporative emission) system (see

page es ...

Other materials:

Suspension system

Problem symptoms table

Hint:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms are

listed in order of probability in the "suspected area" column of

the table. Check each symptom by checking the suspected

areas in the order th ...

Compressor circuit

Description

When the a/c switch is turned on, the magnetic clutch on signal is sent from

the air conditioning

amplifier. Then the mg clt relay turns on to operate the magnetic clutch.

Wiring diagram

Inspection procedure

Inspection procedure

Perform active test by intelligent tester (a ...

Adding engine oil

â– Checking the oil type and

preparing the items needed

Make sure to check the oil type

and prepare the items needed

before adding oil.

Engine oil selection

Oil quantity (Low level mark

Refill upper limit mark)

1.6 qt. (1.5 L, 1.3 Imp. qt.)

Item

Clean funnel

â– Adding engine oil

If the oi ...