Toyota RAV4 (XA40) 2013-2018 Service Manual: Speed sensor

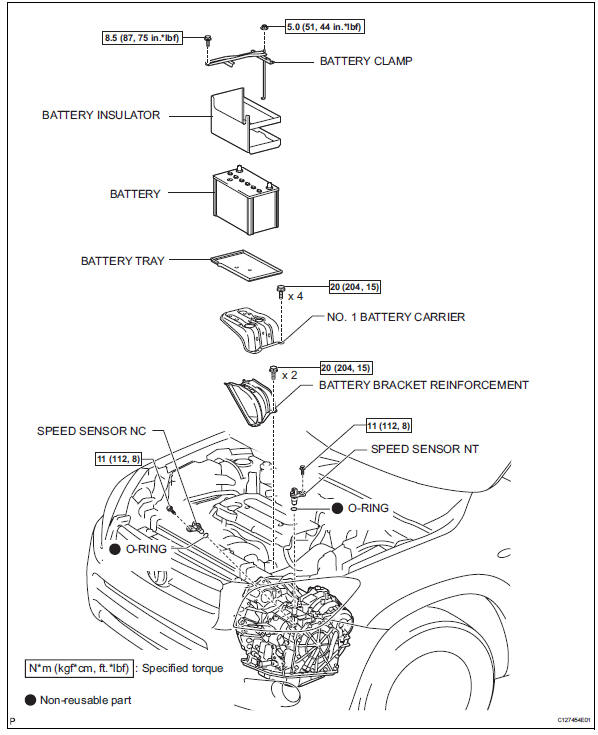

Components

Removal

- Disconnect cable from negative battery terminal

Caution:

Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to prevent airbag and seat belt pretensioner activation.

- Remove battery

- Loosen the nut and remove the bolt and battery clamp.

- Remove the battery.

- Remove the battery tray.

- Remove the 4 bolts and battery carrier.

- Remove the 2 bolts and battery bracket reinforcement.

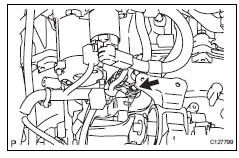

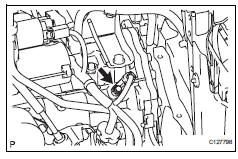

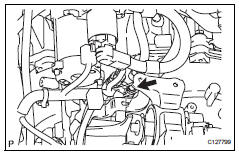

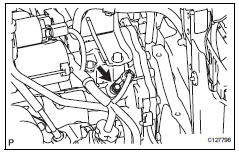

- Remove speed sensor nt

- Disconnect the sensor connector.

- Remove the bolt and sensor.

- Remove the o-ring from the sensor.

- Remove speed sensor nc

- Disconnect the sensor connector.

- Remove the bolt and sensor.

- Remove the o-ring from the sensor.

Inspection

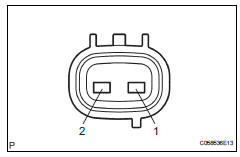

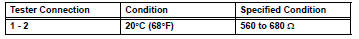

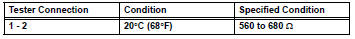

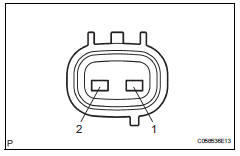

- Inspect speed sensor nt

Measure the resistance of the sensor.

Standard resistance

- Inspect speed sensor nc

Measure the resistance of the sensor.

Standard resistance

Installation

- Install speed sensor nc

- Coat a new o-ring with atf.

- Install the o-ring to the sensor.

- Install the sensor with the bolt.

Torque: 11 n*m (112 kgf*cm, 8 ft.*Lbf)

- Connect the sensor connector.

- Install speed sensor nt

- Coat a new o-ring with atf.

- Install the o-ring to the sensor.

- Install the sensor with the bolt.

Torque: 11 n*m (112 kgf*cm, 8 ft.*Lbf)

- Connect the sensor connector.

- Install battery

- Install the battery bracket reinforcement with the 2 bolts.

Torque: 20 n*m (204 kgf*cm, 15 ft.*Lbf)

- Install the battery carrier with the 4 bolts.

Torque: 20 n*m (204 kgf*cm, 15 ft.*Lbf)

- Install the battery tray.

- Install the battery with the battery clamp.

Torque: 8.5 N*m (87 kgf*cm, 75 in.*Lbf) for bolt

5.0 N*m (51 kgf*cm, 44 in.*Lbf) for nut

- Connect cable to negative battery terminal

Automatic transaxle fluid

Automatic transaxle fluid

On-vehicle inspection

Check transaxle fluid level

Hint:

Drive the vehicle so that the engine and transaxle are at

normal operating temperature.

Fluid temperature:

70 to 80°c (158 to 176°f ...

Transmission wire

Transmission wire

Components

Removal

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

preven ...

Other materials:

Back-up light circuit

Description

The park / neutral position switch turns on when the shift lever is moved

into the r position, causing the

back-up lights to illuminate.

Wiring diagram

Inspection procedure

Inspect fuse (gauge1)

Remove the gauge1 fuse from the instrument panel

junction block.

Meas ...

Receiver error

Description

Wiring diagram

Inspection procedure

Notice:

It is necessary to register an id code after replacing the tire pressure

warning valve abd

transmitter and/or the tire pressure warning ecu (see page tw-9).

Hint:

Set the tire pressure to the specified value.

Standard pres ...

Pressure sensor circuit

Description

This dtc is output when the refrigerant pressure is either extremely low

(0.19 Mpa [2.0 Kgf/cm2, 28 psi]

or less) or extremely high (3.14 Mpa [32.0 Kgf/cm2, 455 psi] or more). The air

conditioning pressure

sensor, which is installed on the pipe of the high pressure side, detec ...