Toyota RAV4 Service Manual: Underdrive planetary gear

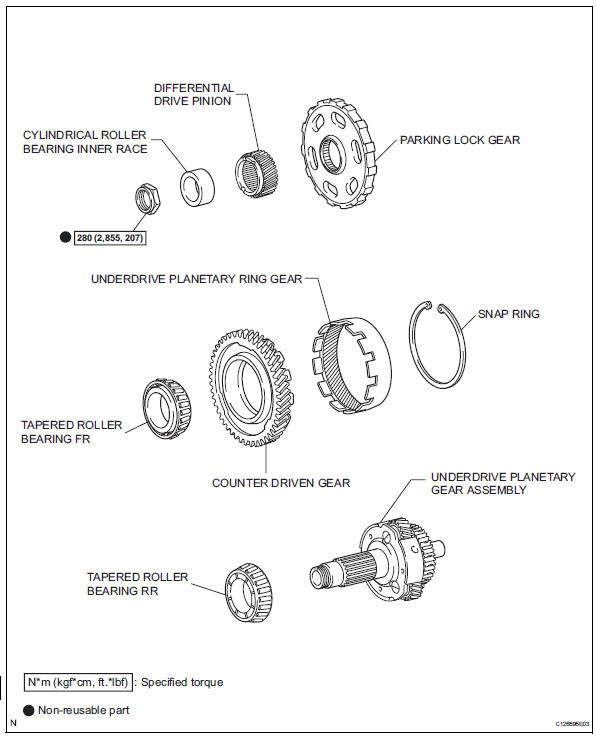

Components

Disassembly

- Remove underdrive planetary gear preload (see page ax-240)

- Remove underdrive input shaft nut

Sst 09930-00010 (09931-00010, 09931-00020), 09387-00050, 09564-16020

- Using sst, loosen the staked part of the nut.

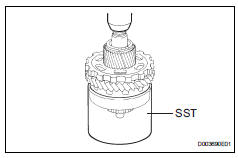

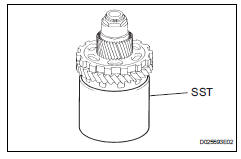

- Clamp the underdrive planetary gear in soft jaw vise.

Notice:

Be careful not to damage the differential drive pinion.

- Using sst, remove the lock nut.

Sst 09387-00050

- Remove cylindrical roller bearing inner race

- Using sst, remove the cylindrical roller bearing race inner.

Sst 09950-00020, 09950-00030, 09950-60010 (09951-00340)

- Remove underdrive planetary gear assembly

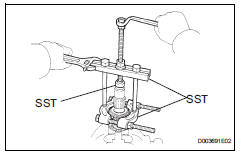

- Using sst and a press, remove the differential drive pinion, parking lock gear, counter driven gear with underdrive planetary ring gear and front tapered roller bearing.

Sst 09387-00050

- clamp the underdrive planetary gear in soft jaw vise.

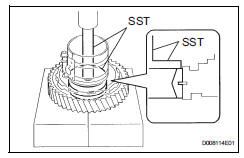

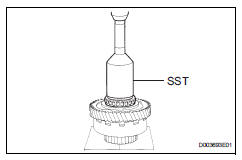

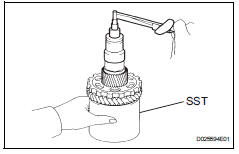

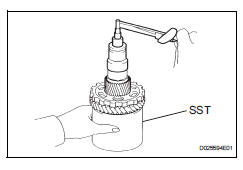

- Using sst, remove the rear tapped roller bearing from the underdrive planetary gear.

Sst 09950-00020, 09950-00030, 09950-60010 (09951-00340)

- Remove underdrive planetary ring gear

- Using snap ring pliers, remove the snap ring.

- Remove the underdrive planetary ring gear from the counter driven gear.

Inspection

- Inspect underdrive planetary gear preload

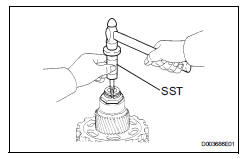

- Using sst, fix the underdrive planetary gear.

Sst 09387-00050

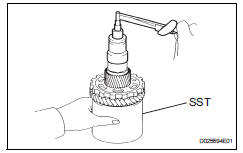

- Using sst and a torque wrench, measure the turning torque of the underdrive planetary gear in place while rotating the torque wrench at 60 rpm.

Sst 09387-00050

Torque: turning torque at 60 rpm

0.10 To 4.41 N*m (1.0 To 45 kgf*cm, 0.9 To 39 in.*Lbf)

Hint:

Use a torque wrench with a fulcrum length of 160 mm (6.3 In.)

Reassembly

- Install underdrive planetary ring gear

- Install a new snap ring to the outer race of the tapered roller bearing.

- Using a piston ring compressor, squeeze the snap ring.

- Using sst a press, press in the outer race of the tapered roller bearing.

Sst 09950-60020 (09951-00890), 09950-70010 (09951-07100)

- Install the underdrive planetary ring gear to the counter driven gear.

- Using snap ring pliers, install the snap ring.

- Install underdrive planetary gear assembly

- Using a press, press in the rear tapered roller bearing to the underdrive planetary gear.

Notice:

Press in the bearing until it becomes flat at the bottom

- Press in the bearing until it becomes flat at the bottom

- Using sst and a press, press in the front tapered roller bearing.

Sst 09214-76011

Notice:

Press in the counter driven gear while rotating it.

- Using a press, press in the parking lock gear.

Notice:

Press in the counter driven gear while rotating it.

- Install cylindrical roller bearing inner race

- Using a press, press in the cylindrical roller bearing race inner.

Notice:

Press in the counter driven gear while rotating it.

- Install underdrive input shaft nut

- Clamp the underdrive planetary gear in a soft jaw vise.

Notice:

Be careful not to damage the differential drive pinion.

- Using a socket wrench, install a new lock nut.

Torque: 280 n*m (2,855 kgf*cm, 207 in.*Lbf)

Hint:

Use a torque wrench with a fulcrum length of 750 mm (29.53 In.)

- Inspect underdrive planetary gear preload

- Using sst and a torque wrench, measure the turning torque of underdrive planetary gear assembly while rotating the torque wrench at 60 rpm.

Sst 09387-00050

Torque: turning torque at 60 rpm 0.10 To 4.41 N*m (1.0 To 45 kgf*cm, 0.9 To 39 in.*Lbf)

Hint:

Use a torque wrench with a fulcrum length of 160 mm (6.30 In.)

- Using a pin punch and a hammer, stake the lock nut.

Notice:

Make sure that there are no cracks on the nut.

Direct clutch

Direct clutch

Components

Disassembly

Inspect pack clearance of direct clutch

(see page ax-234)

Remove direct multiple disc clutch disc

Using a screwdriver, pry out the snap ring from the

direct ...

Underdrive clutch

Underdrive clutch

Components

Disassembly

Inspect pack clearance of underdrive

clutch (see page ax-247)

Remove no. 1 Underdrive clutch disc

Using a screwdriver, pry out the underdrive clutch

fla ...

Other materials:

Sliding roof control switch circuit

Description

If either the sliding function or tilt function does not operate, there may

be a malfunction in the sliding roof

control switch circuit.

Wiring diagram

Inspection procedure

Perform active test by intelligent tester (sliding roof operation)

Select the active test, use ...

Antenna location and effective range

Antenna location

Antennas outside the cabin

Antennas inside the cabin

Antenna outside the luggage

compartment

Effective range (areas within which the electronic key is

detected)

When locking or unlocking

the doors

The system can be operated

when the electronic key is with ...

Fuel pressure pulsation damper

Components

Removal

Discharge fuel system pressure (see page

fu-9)

Disconnect cable from negative battery

terminal

Remove no. 1 Engine cover (see page es-410)

Remove air cleaner cap sub-assembly (see

page es-411)

Disconnect fuel main tube (see page fu-10)

Remove fuel pres ...