Toyota RAV4 (XA40) 2013-2018 Service Manual: Basic repair hint

- Hints on operations

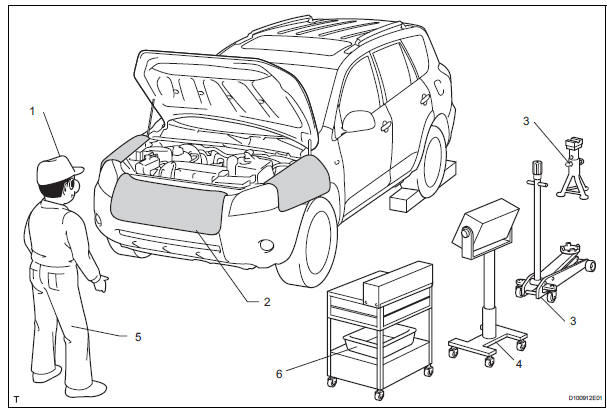

| 1 | Attire |

|

| 2 | Vehicle protection | Prepare a grille cover, fender cover, seat cover and floor mat before starting the operation. |

| 3 | Safe operation |

|

| 4 | Preparation of tools and measuring gauge | Before starting the operation, prepare a tool stand, sst, gauge, oil and parts for replacement. |

| 5 | Removal and installation, disassembly and assembly operations |

|

| 6 | Removed parts |

|

- Jacking up and supporting vehicle

- Care must be taken when jacking up and supporting the vehicle. Be sure to lift and support the vehicle at the proper locations.

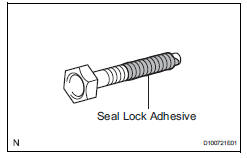

- Precoated parts

- Precoated parts are bolts and nuts that are coated with a seal lock adhesive at the factory.

- If a precoated part is retightened, loosened or moved in any way, it must be recoated with the specified adhesive.

- When reusing a precoated part, clean off the old

adhesive and dry the part with compressed air.

Then apply new seal lock adhesive appropriate to that part.

- Some seal lock agents harden slowly. You may have to wait for the seal lock adhesive to harden.

- Gaskets

- When necessary, use a sealer on gaskets to prevent leaks.

- Bolts, nuts and screws

- Carefully follow all the specifications for tightening torques. Always use a torque wrench.

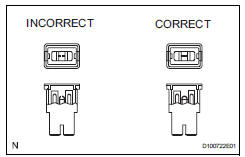

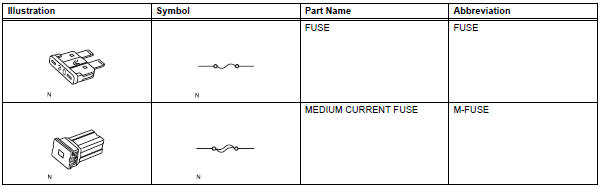

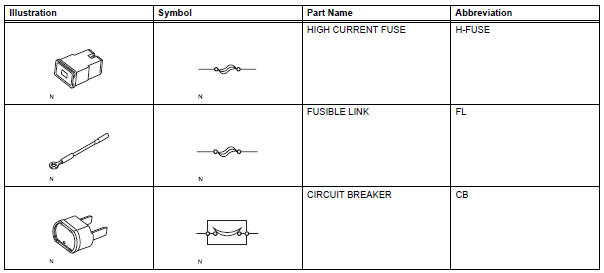

- Fuses

- When inspecting a fuse, check that the wire of the fuse is not broken.

- When replacing fuses, be sure that the new fuse has the correct amperage rating. Do not exceed the rating or use one with a lower rating.

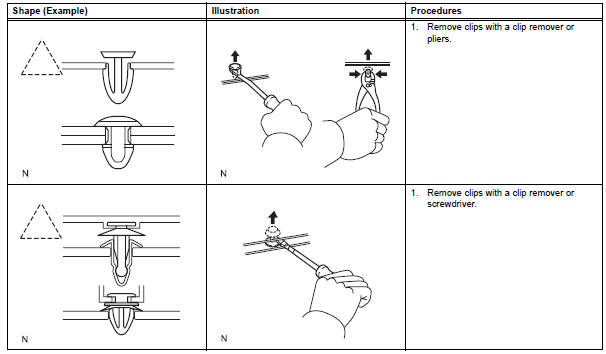

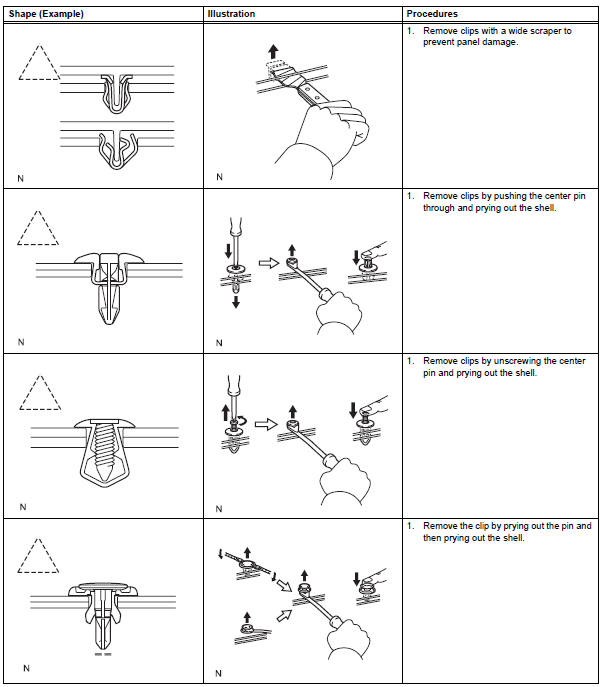

- Clips

Hint:

If clips are damaged during a procedure, always replace the clips with new clips.

- The removal and installation methods of typical clips used for vehicle body parts are shown in the table below.

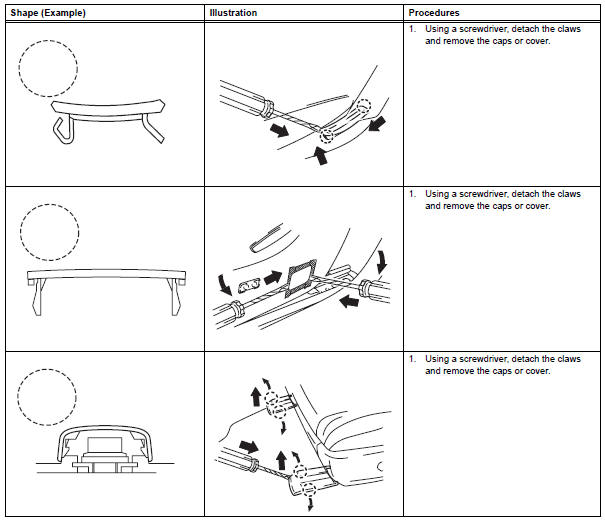

- Claws

- The removal and installation methods of typical claws used for vehicle body parts are shown in the table below.

Hint:

If claws of caps or covers are damaged during a procedure, always replace the caps or covers with new ones.

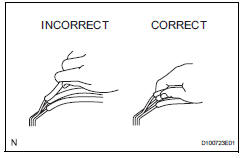

- Removal and installation of vacuum hoses.

- To disconnect a vacuum hose, pull and twist from the end of the hose. Do not pull from the middle of the hose as this may cause damage.

- When disconnecting vacuum hoses, use tags to identify where they should be reconnected.

- After completing any hose related repairs, double-check that the vacuum hoses are properly connected. The label under the hood shows the proper layout.

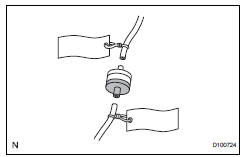

- When using a vacuum gauge, never force the hose onto a connector that is too large. If a hose has been stretched, it may leak air. Use a stepdown adapter if necessary.

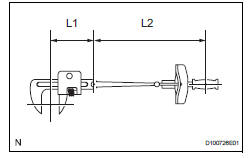

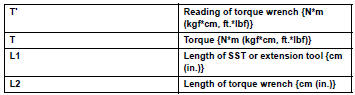

- Torque when using torque wrench with extension tool

- Use the formula below to calculate special torque values for situations where sst or an extension tool is combined with a torque wrench.

Formula: t' = l2 / (l1 + l2) * t

Notice:

If an extension tool or sst is combined with a torque wrench and the wrench is used to tighten to a torque specification in this manual, the actual torque will be excessive and parts will be damaged.

Precaution

Precaution

...

For vehicles with supplemental restraint system

For vehicles with supplemental restraint system

The rav4 is equipped with a supplemental restraint

system (srs). The srs of this vehicle consists of the

following:

Steering pad

Front passenger airbag assembly

Front seat side airbag assemb ...

Other materials:

Summary of the blind spot monitor

The blind spot monitor is a system that has 2 functions;

The blind spot monitor function

Assists the driver in making the decision when changing lanes

The rear cross traffic alert function

Assists the driver when backing up

These functions use same sensors.

Bsm main switch

...

Short in front driver side pretensioner squib circuit

Description

The driver side front pretensioner squib circuit consists of the center

airbag sensor and the front seat

outer belt lh.

This circuit instructs the srs to deploy when the deployment conditions are met.

These dtcs are recorded when a malfunction is detected in the front prete ...

General maintenance (2005/11-2006/01)

General notes

Maintenance requirements vary depending on the

country.

Check the maintenance schedule in the owner's

manual supplement.

Following the maintenance schedule is mandatory.

Determine the appropriate time to service the vehicle

using either miles driven or time elapsed ...