Toyota RAV4 (XA40) 2013-2018 Service Manual: Reassembly

- Install generator rotor assembly

- Install the washer onto the generator rectifier end frame.

- Install the generator rotor onto the generator rectifier end frame.

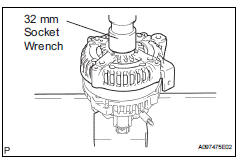

- Using a 32 mm socket wrench and press, slowly push the generator drive end frame onto the generator rectifier end frame.

- Tighten the 4 bolts.

Torque: 5.8 N*m (59 kgf*cm, 51 in.*Lbf)

- Install the cord clip with the bolt.

Torque: 4.6 N*m (47 kgf*cm, 41 in.*Lbf)

- Install generator brush holder assembly

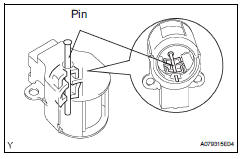

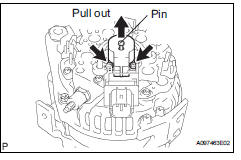

- While pushing the 2 brushes into the generator brush holder, insert a 1.0 Mm (0.039 In.) Pin into the generator brush holder.

- Install the generator brush holder with the 2 screws.

Torque: 1.8 N*m (18 kgf*cm, 16 in.*Lbf)

- Pull the pin out of the generator brush holder.

- Install the terminal insulator onto the generator rectifier end frame.

- Install the generator rear end cover with the 3 nuts.

Torque: 4.6 N*m (47 kgf*cm, 41 in.*Lbf)

Install generator pulley with clutch

- Install the pulley by hand.

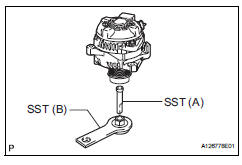

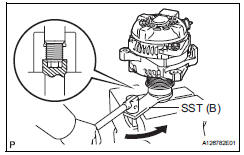

- Install sst to the pulley and vise as shown in the illustration.

Sst 09820-63020

- Turn sst (b) counterclockwise to tighten the pulley.

Torque: 111 n*m (1125 kgf*cm, 81 ft.*Lbf)

- Install a new cap to the pulley.

- Check that the generator pulley rotates smoothly.

Replacement

Replacement

Replace generator drive end frame bearing

Remove the 4 screws and bearing retainer.

Using sst and a hammer, tap out the bearing.

Sst 09950-60010 (09951-00250), 09950-70010

(0995 ...

Installation

Installation

Install generator assembly

Confirm that the wire harness of the crankshaft

position sensor is secured to the wire harness

clamp bracket through the back of the rib of the

timing cha ...

Other materials:

Front occupant classification sensor lh collision detection

Description

Dtc b1785 is output when the occupant classification ecu receives a collision

detection signal sent by

the front occupant classification sensor lh when an accident occurs.

Dtc b1785 is also output when the front seat rh is subjected to a strong impact,

even if an actual

acc ...

Spiral cable

Components

Removal

Caution:

Be sure to read the precautionary notices concerning the

srs airbag system before servicing it (see page rs-1).

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery ...

Parking Support Brake function

(static objects)

If the sensors detect a static object, such as a wall, in the

traveling direction of the vehicle and the system determines

that a collision may occur due to the vehicle suddenly moving

forward due to an accidental accelerator pedal operation, the

vehicle moving the unintended direction due to the wr ...