Toyota RAV4 (XA40) 2013-2018 Service Manual: Transmission wire

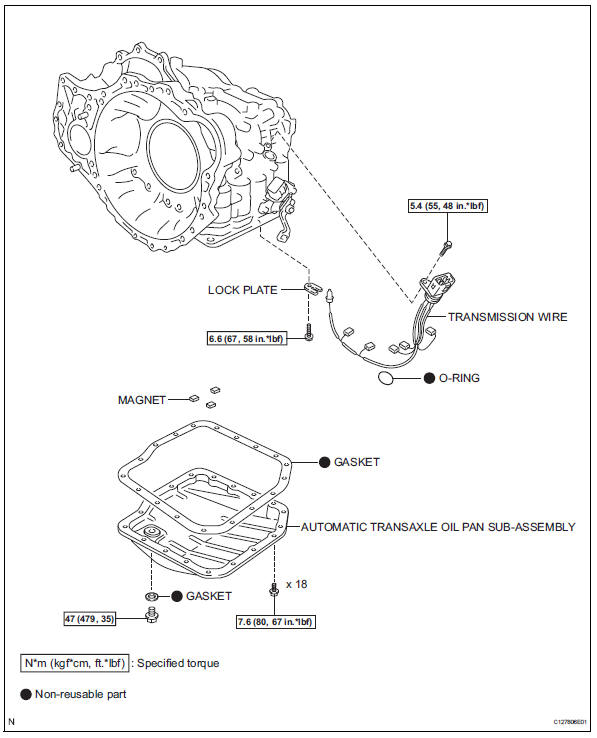

Components

Removal

- Disconnect cable from negative battery terminal

Caution:

Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to prevent airbag and seat belt pretensioner activation.

- Remove no. 1 Engine under cover

- Drain automatic transaxle fluid

- Remove the drain plug and gasket, and drain atf.

- Install a new gasket and the drain plug.

Torque: 47 n*m (479 kgf*cm, 35 ft.*Lbf)

- Remove automatic transaxle oil pan subassembly

- Remove the 18 bolts, oil pan and gasket.

Notice:

Some fluid will remain in the oil pan. Carefully remove the oil pan.

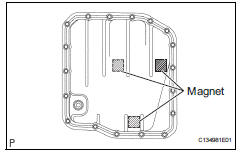

- Remove the 3 magnets from the oil pan.

- Examine particles in the pan.

- Use the removed magnets to collect any steel

chips. Look carefully at the chips and particles

in the pan and on the magnet to anticipate what

type of wear you will find in the transaxle.

Steel (magnetic): bearing, gear and plate wear brass (non-magnetic): bush wear

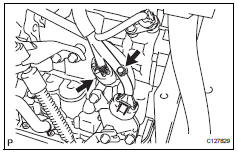

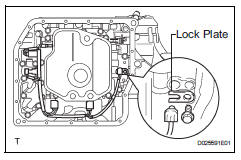

- Remove transmission wire

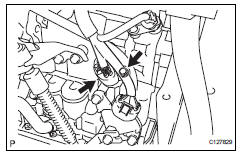

- Disconnect the 5 shift solenoid valve connectors.

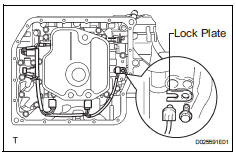

- Remove the bolt, lock plate and atf temperature sensor.

- Disconnect the transmission wire connector.

- Remove the bolt and transmission wire.

- Remove the o-ring from the transmission wire.

Inspection

- Inspect transmission wire

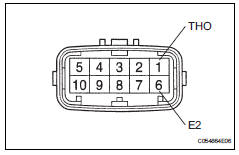

- Disconnect the b27 wire connector.

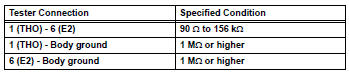

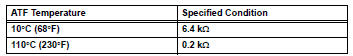

- Measure the resistance of the transmission wire.

Standard resistance

Hint:

If the resistance is not as specified for either of the atf temperatures shown in the table below, the driveability of the vehicle may decrease.

Standard resistance

Installation

- Install transmission wire

- Coat a new o-ring of the transmission wire connector with atf.

- Install the transmission wire.

- Install the bolt.

- Connect the connector.

- Coat the o-ring of the atf temperature sensor with atf.

- Install the atf temperature sensor with the lock plate and bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*Lbf)

- Connect the 5 shift solenoid valve connectors.

- Install automatic transaxle oil pan subassembly

- Install the 3 magnets in the oil pan.

- Install a new gasket and the oil pan with the 18 bolts.

Torque: 7.6 N*m (77 kgf*cm, 67 in.*Lbf)

- Install no. 1 Engine under cover

- Connect cable to negative battery terminal

- Add automatic transaxle fluid

Fluid type: toyota genuine atf ws

- Inspect transaxle fluid level

- Inspect the fluid level (see page ax-102).

- Perform reset memory

- Perform the reset memory procedures (a/t initialization) (see page ax-18).

Speed sensor

Speed sensor

Components

Removal

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent ai ...

Valve body assembly

Valve body assembly

Components

Removal

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

preven ...

Other materials:

Blind Spot Monitor operation

â– Objects that can be detected while driving

The Blind Spot Monitor uses rear side radar sensors to detect the

following vehicles traveling in adjacent lanes and advises the driver

of the presence of such vehicles via the indicators on the outside

rear view mirrors.

Vehicles that are traveling ...

Low pitched horn

Components

Removal

Remove radiator support opening cover

(see page et-4)

Remove front fender liner lh (see page et-4)

Remove front fender liner rh (see page et-4)

Remove front bumper cover (see page et-5)

Remove low pitched horn

Disconnect the horn connector.

Remove th ...

How to proceed with troubleshooting

Hint:

Use these procedures to troubleshoot the engine immobiliser

system.

*: Use the intelligent tester.

Vehicle brought to workshop

Inspect battery voltage

Standard voltage:

11 to 14 v

If the voltage is below 11 v, recharge or replace the battery

before proceeding.

cran ...