Toyota RAV4 (XA40) 2013-2018 Service Manual: Disassembly

- Remove radio setting condenser

- Remove the bolt and condenser.

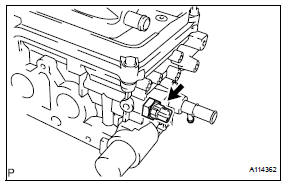

- Remove oil pressure switch

- Using a 24 mm deep socket wrench, remove the sensor.

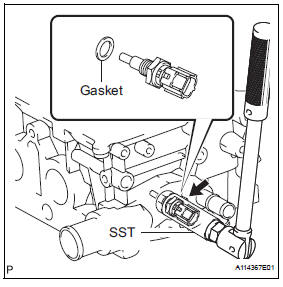

- Remove engine coolant temperature sensor

- Using sst, remove the sensor and gasket.

Sst 09817-33190

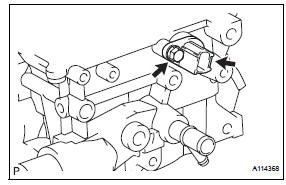

- Remove camshaft position sensor

- remove the bolt and sensor.

- Remove no. 2 Camshaft bearing

- Remove the no. 2 Camshaft bearing.

- Remove no. 1 Camshaft bearing

- Remove the no. 1 Camshaft bearing.

- Remove valve lifter

Hint:

Arrange the valve lifters in the correct order.

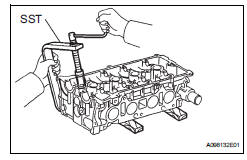

- Remove intake valve

- Place the cylinder head on wooden blocks.

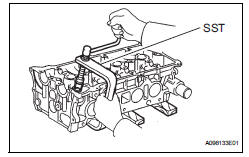

- Using sst, compress the spring, then remove the 2 retainer locks.

Sst 09202-70020 (09202-00010)

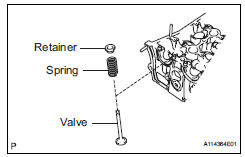

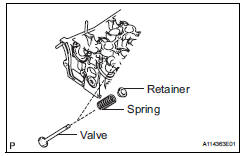

- Remove the retainer, spring and valve from the cylinder head.

Hint:

Arrange the removed parts in the correct order.

- Remove exhaust valve

- Place the cylinder head on wooden blocks.

- Using sst, compress the spring, then remove the 2 retainer locks.

Sst 09202-70020 (09202-00010)

- Remove valve spring seat

- Using compressed air and a magnetic finger, remove the spring seat by blowing air.

Hint:

Arrange the valves, valve springs, spring seats and spring retainers in the correct order.

- Remove valve stem oil seal

- Using needle-nose pliers, remove the 16 oil seals.

Removal

Removal

Discharge fuel system pressure (see page

fu-9)

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) batte ...

Inspection

Inspection

Inspect cylinder head for warpage

Using a precision straightedge and feeler gauge,

measure the warpage of the contact surfaces of the

cylinder block and manifolds.

Maximum warpage: ...

Other materials:

Playing back mp3 and wma discs

Power

Volume

Cd eject

Selecting a file or displaying

folder list

Searching playback

Next commands, random play

or back button

Repeat play

Fast-forwarding, rewinding or

selecting a folder

Changing the audio source/

playback

Playback/pause

Previous commands

Selecti ...

Registering a bluetoothÂź

phone for the first time

To use the hands-free system, it is necessary to register a

bluetoothÂź phone with the system.

Once the phone has been registered, it is possible to use the

hands-free system.

For details about registering a bluetoothÂź device

Turn the bluetoothÂź connection setting of your cellular phon ...

Diagnosis system

Description

The center airbag sensor controls the functions of the

supplemental restraint system (srs) on the vehicle.

Data of the srs can be read in the data link connector

3 (dlc3) of the vehicle. When the system seems to be

malfunctioning, use the intelligent tester to check for a

ma ...