Toyota RAV4 (XA40) 2013-2018 Service Manual: On-vehicle inspection

Notice:

- Perform the maf meter inspection according to the procedures below.

- Only replace the maf meter when both the long ft#1 value and maf value in the data list (with the engine stopped) are not within the normal operating range.

- Inspect mass air flow meter

- Perform confirmation driving pattern.

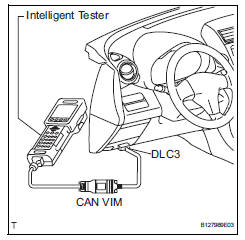

- Connect the intelligent tester to the dlc3.

- Turn the ignition switch on.

- Turn the tester on.

- Clear the dtcs (see page es-35).

- Start the engine and warm it up with all accessory switches off until the engine coolant temperature is 75°c (167°f) or more.

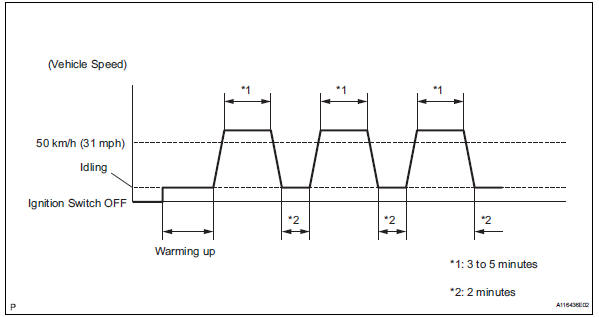

- Drive the vehicle at 50 km/h (31 mph) or more for 3 to 5 minutes*1.

- Allow the engine to idle for 2 minutes*2.

- Perform steps *1 and *2 at least 3 times.

- Read the value using the intelligent tester (long ft#1).

- Select the following menu items: diagnosis / enhanced obd ii / data list / primary / long ft#1.

- Read the values displayed on the tester.

Standard value: within -15 to +15%

If the result is not within the specified range, perform the inspection below.

- Read the value using the intelligent tester (maf).

Notice:

- Turn off the engine.

- Perform the inspection with the vehicle indoors and on a level surface.

- Perform the inspection of the maf meter while it is installed to the air cleaner case (installed to the vehicle).

- During the test, do not use the exhaust air duct to perform suction on the exhaust pipe.

- Turn the ignition switch to acc.

- Turn the ignition switch on (do not run the engine).

- Turn the tester on.

- Select the following menu items: diagnosis / enhanced obd ii / data list / primary / maf.

- Wait 30 seconds, and read the values on the intelligent tester.

Standard condition: less than 0.45 G/sec.

- If the result is not as specified, replace the maf meter.

- If the result is within the specified range, inspect the cause of the extremely rich or lean air-fuel ratio (see page es-147).

Mass air flow meter

Mass air flow meter

Components

...

Removal

Removal

Disconnect cable from negative battery terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensi ...

Other materials:

Open in abs solenoid relay circuit

Description

The solenoid relay supplies power to the abs solenoid and trc solenoid.

After the ignition switch is turned on, the vehicle speed has reached 6 km/h (4

mph) and the solenoid is

determined to be normal by the initial check self-diagnosis, the relay switches

on. If any open or ...

Checking and replacing

fuses

If any of the electrical components do not operate, a fuse may

have blown. If this happens, check and replace the fuses as necessary.

Vehicles without a smart key system:

turn the engine switch to the “lock” position.

Vehicles with a smart key system:

turn the engine switch off.

Aft ...

If the engine will not start

If the engine will not start

even though correct starting

procedures are being

followed, consider

each of the following

points:

The engine will not start

even though the starter

motor operates normally

One of the following may be the

cause of the problem:

There may not be sufficient

fuel in the v ...