Toyota RAV4 (XA40) 2013-2018 Service Manual: Passenger side buckle switch circuit malfunction

Description

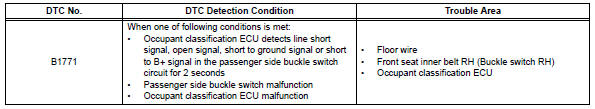

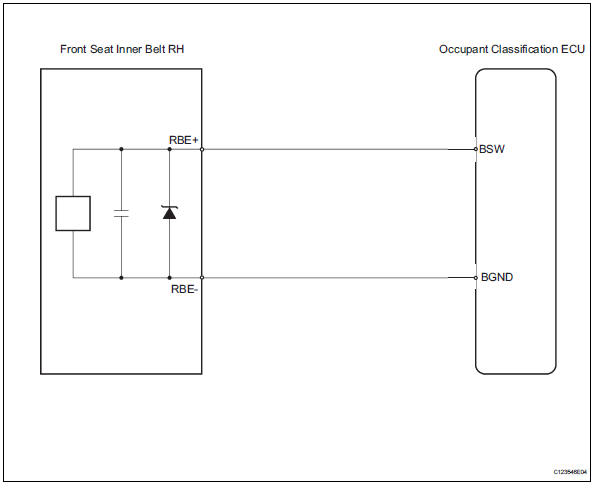

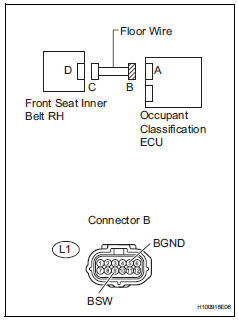

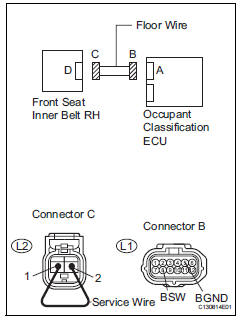

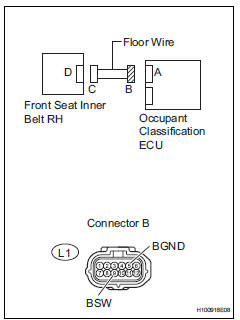

The passenger side buckle switch circuit consists of the occupant classification ecu and the front seat inner belt rh.

Dtc b1771 is recorded when a malfunction is detected in the passenger side buckle switch circuit.

Troubleshoot dtc b1771 first when dtcs b1771 and b1795 are output simultaneously

Wiring diagram

Inspection procedure

Hint

- If troubleshooting (wire harness inspection) is difficult to perform, remove the front passenger seat installation bolts to see the undersurface of the seat cushion.

- In the above case, hold the seat so that it does not tip over. Holding the seat for a long period of time may cause a problem, such as seat rail deformation. Hold the seat up only for as long as necessary.

- Check for dtc

- Turn the ignition switch on.

- Clear the dtcs (see page rs-249).

Hint:

First clear dtcs stored in the occupant classification ecu and then in the center airbag sensor.

- Turn the ignition switch off.

- Turn the ignition switch on.

- Check the dtcs (see page rs-249).

Ok: dtc b1771 is not output.

Hint:

Dtcs other than dtc b1771 may be output at this time, but they are not related to this check.

- Check connection of connector

- Turn the ignition switch off.

- Disconnect the cable from the negative (-) battery terminal, and wait for at least 90 seconds.

- Check that the connectors are properly connected to the occupant classification ecu and the front seat inner belt rh.

Ok: the connectors are properly connected.

- Check floor wire (to b+)

- Disconnect the connectors from the occupant classification ecu and the front seat inner belt rh.

- Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

- Turn the ignition switch on.

- Measure the voltage of the wire harness side connector.

Standard voltage

- Check floor wire (for open)

- Turn the ignition switch off.

- Disconnect the cable from the negative (-) battery terminal, and wait for at least 90 seconds

- Using a service wire, connect terminals l2-2 and l2-1 of connector c.

Notice:

Do not forcibly insert a service wire into the terminals of the connector when connecting them.

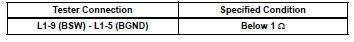

- Measure the resistance of the wire harness side connectors.

Standard resistance

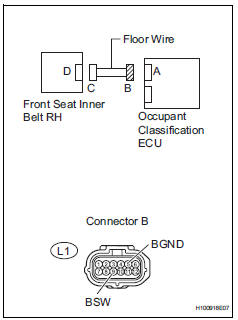

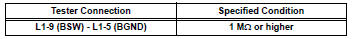

- Check floor wire (for short)

- Disconnect the service wire from connector c.

- Measure the resistance of the wire harness side connector.

Standard resistance

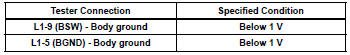

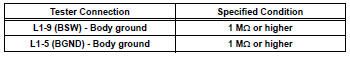

- Check floor wire (to ground)

- Measure the resistance of the wire harness side connector.

Standard resistance

- Check for dtc

- Connect the connectors to the occupant classification ecu and the front seat inner belt rh.

- Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

- Turn the ignition switch on.

- Clear the dtcs (see page rs-249).

Hint:

First clear dtcs stored in the occupant classification ecu and then in the center airbag sensor.

- Turn the ignition switch off.

- Turn the ignition switch on.

- Check the dtcs (see page rs-249).

Ok: dtc b1771 is not output.

Hint

Dtcs other than dtc b1771 may be output at this time, but they are not related to this check.

- Replace front seat inner belt assembly rh

- Turn the ignition switch off.

- Disconnect the cable from the negative (-) battery terminal, and wait for at least 90 seconds.

- Replace the front seat inner belt rh (see page sb-21).

Hint:

Perform the inspection using parts from a normal vehicle if possible.

- Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

- Turn the ignition switch on.

- Clear the dtcs (see page rs-249).

Hint:

First clear dtcs stored in the occupant classification ecu and then in the center airbag sensor.

- Turn the ignition switch off.

- Turn the ignition switch on.

- Check the dtcs (see page rs-249).

Ok: dtc b1771 is not output.

Hint:

Dtcs other than dtc b1771 may be output at this time, but they are not related to this check.

- Replace occupant classification ecu

- Turn the ignition switch off.

- Disconnect the cable from the negative (-) battery terminal, and wait for at least 90 seconds.

- Replace the occupant classification ecu (see page rs- 392).

- Perform zero point calibration

- Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

- Connect the intelligent tester (with can vim) to the dlc3.

- Turn the ignition switch on.

- Using the intelligent tester, perform the zero point calibration (see page rs-241).

Ok: completed is displayed.

- Perform sensitivity check

- Using the intelligent tester, perform the sensitivity check (see page rs-241).

Standard value: 27 to 33 kg (59.52 To 72.75 Lb)

End

Diagnostic trouble code chart

Diagnostic trouble code chart

If a trouble code is displayed during the dtc check, check

the circuit listed for the code in the table below (proceed to

the page listed for that circuit).

...

Front occupant classification sensor lh circuit

malfunction

Front occupant classification sensor lh circuit

malfunction

Description

The front occupant classification sensor lh circuit consists of the occupant

classification ecu and the

front occupant classification sensor lh.

Dtc b1780 is recorded when a mal ...

Other materials:

Rear occupant classification sensor lh circuit malfunction

Description

The rear occupant classification sensor lh circuit consists of the occupant

classification ecu and the rear

occupant classification sensor lh.

Dtc b1782 is recorded when a malfunction is detected in the rear occupant

classification sensor lh

circuit.

Wiring diagram

...

Inspection

Inspect crankshaft position sensor

Measure the resistance of the sensor.

Standard resistance

Notice:

Cold and hot mean the temperature of the coils

themselves. Cold is from -10 to 50ÂḞc (14 to

122ÂḞf) and hot is from 50 to 100ÂḞc (122 to

212ÂḞf).

If the result is not as specif ...

Brake Hold

The brake hold system

keeps the brake applied

when the shift lever is in D,

S or N with the system on

and the brake pedal has

been depressed to stop the

vehicle. The system

releases the brake when the

accelerator pedal is

depressed with the shift

lever in D or S to allow

smooth start off.

Enabling t ...