Toyota RAV4 (XA40) 2013-2018 Service Manual: Pressure control solenoid "b" electrical (shift solenoid valve sl2)

Description

Shifting from 1st to o/d is performed in combination with the on and off operation of the shift solenoid valves sl1 and sl2, which are controlled by the ecm. If an open or short circuit occurs in any of the shift solenoid valves, the ecm controls the remaining normal shift solenoid valves to allow the vehicle to be operated safely (see page ax-31).

Monitor description

This dtc indicates an open or short in the shift solenoid valve sl2 circuit. The ecm commands gear shifts by turning the shift solenoid valves on/off. When there is an open or short circuit in any shift solenoid valve circuit, the ecm detects the problem, illuminates the mil and stores the dtc. Also, the ecm performs the fail-safe function and turns the other normal shift solenoid valves on/off. In case of an open or short circuit, the ecm stops sending current to the circuit (see page ax-31).

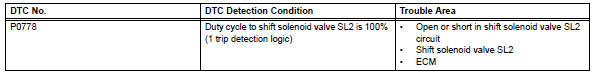

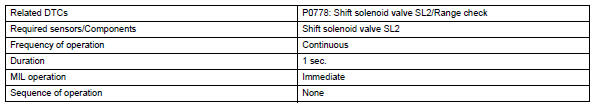

Monitor strategy

Typical enabling conditions

Typical malfunction thresholds

![]()

Component operating range

![]()

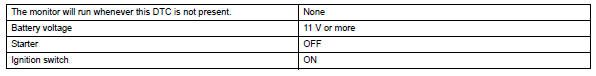

Wiring diagram

Inspection procedure

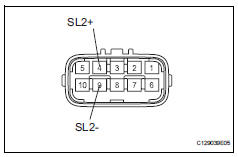

- Inspect transmission wire (shift solenoid valve sl2)

- Disconnect the b27 wire connector.

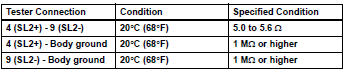

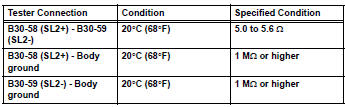

- Measure the resistance of the transmission wire.

Standard resistance

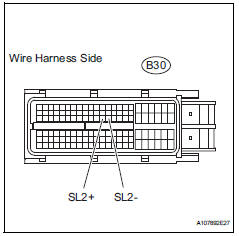

- Check wire harness (transmission wire - ecm)

- Disconnect the b30 ecm connector.

- Measure the resistance of the wire harness side connector.

Standard resistance

Replace ecm

- Inspect shift solenoid valve sl2

- Remove the shift solenoid valve sl2.

- Measure the resistance of the solenoid valve.

Standard resistance: 5.0 To 5.6 Ùat 20°c (68°f)

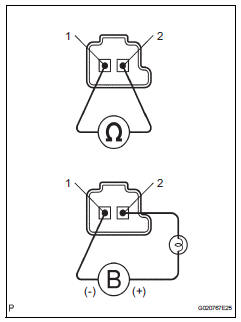

- Connect the battery's positive (+) lead with a 21 w bulb to terminal 2 and the negative (-) lead to terminal 1 of the solenoid valve connector. Then check that the valve moves and makes an operating noise.

Ok: valve moves and makes operating noise.

Repair or replace transmission wire

Pressure control solenoid "B" performance (shift solenoid valve sl2)

Pressure control solenoid "B" performance (shift solenoid valve sl2)

Description

The ecm uses signals from the output shaft speed sensor and input speed

sensor to detect the actual

gear position (1st, 2nd, 3rd or o/d gear).

Then the ecm compares the actual g ...

Intermediate shaft speed sensor "A"

Intermediate shaft speed sensor "A"

Description

This sensor detects the rotation speed of the counter gear. By comparing the

counter gear speed signal

(nc) with the direct clutch speed sensor signal (nt), the ecm detects the shi ...

Other materials:

Suspension & axle front shock absorber with coil spring (for sport package)

Components

Removal

Hint:

Use the same procedures for the rh side and lh side.

The procedures listed below are for the lh side.

Remove front wheel

Remove front speed sensor lh (see page bc-

191)

Remove front stabilizer link assembly lh

(see page sp-30)

Remove front shock a ...

Wheels

If a wheel is bent, cracked or heavily corroded, it should be

replaced. Otherwise, the tire may separate from the wheel or

cause a loss of handling control.

Wheel selection

When replacing wheels, care should be taken to ensure that they are

equivalent to those removed in load capacity, diameter ...

Crankshaft position sensor "A"

Description

The crankshaft position (ckp) sensor system consists of a ckp sensor plate

and a pickup coil.

The sensor plate has 34 teeth and is installed on the crankshaft. The pickup

coil is made of wound copper

wire, an iron core and magnet. The sensor plate rotates and, as each tooth ...