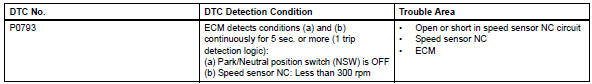

Toyota RAV4 (XA40) 2013-2018 Service Manual: Intermediate shaft speed sensor "A"

![]()

Description

This sensor detects the rotation speed of the counter gear. By comparing the counter gear speed signal (nc) with the direct clutch speed sensor signal (nt), the ecm detects the shift timing of the gears and approximately controls the engine torque and hydraulic pressure according to various conditions. Thus smooth gear shifting is performed.

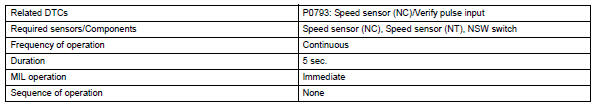

Monitor description

The nc terminal of the ecm detects revolution signals from speed sensor nc (counter gear rpm). The ecm calculates gear shifts by comparing speed sensor nt with speed sensor nc.

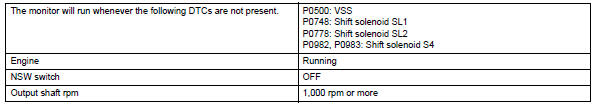

While the vehicle is operating in the 2nd, 3rd or o/d gear position with the shift lever on d, if the counter gear revolution is less than 300 rpm*1 and the output shaft revolution is more than 1,000 rpm*2, the ecm detects the trouble, illuminates the mil and stores the dtc.

*1: Pulse is not output or is irregularly output.

*2: The vehicle speed is 50 km/h (31 mph) or more.

Monitor strategy

Typical enabling conditions

Typical malfunction thresholds

![]()

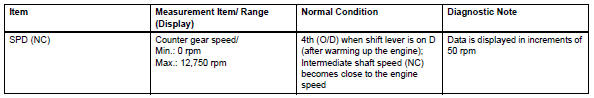

Component operating range

![]()

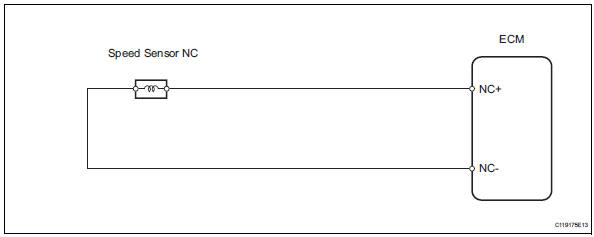

Wiring diagram

Inspection procedure

Hint:

Using the intelligent tester's data list allows switch, sensor, actuator and other item values to be read without removing any parts. Reading the data list early in troubleshooting is one way to save time.

Notice:

In the table below, the values listed under "normal condition" are reference values. Do not depend solely on these reference values when deciding whether a part is faulty or not.

- Warm up the engine.

- Turn the ignition switch off.

- Connect the intelligent tester to the can vim. Then connect the can vim to the dlc3.

- Turn the ignition switch on and turn the tester on.

- Enter the following menus: diagnosis / enhanced obd ii / data list.

- Follow the instructions on the tester and read the data list.

Hint:

- Spd (nc) is always 0 rpm while driving: open or short in the sensor or circuit.

- Spd (nc) is always more than 0 and less than 300 rpm while driving the vehicle at 50 km/h (31 mph) or more: sensor trouble, improper installation, or intermittent connection trouble of the circuit.

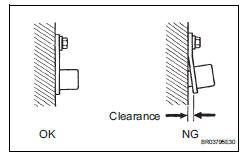

- Inspect speed sensor (installation)

- Check the speed sensor nc installation.

Ok: installation bolt is tightened properly and there is no clearance between the sensor and transaxle case.

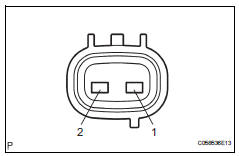

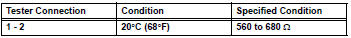

- Inspect speed sensor nc

- Disconnect the b24 sensor connector from the transaxle.

- Measure the resistance of the sensor.

Standard resistance

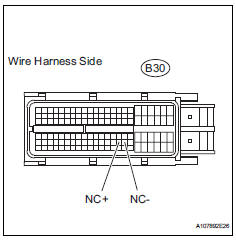

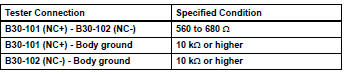

- Check wire harness (speed sensor - ecm)

- Disconnect the b30 ecm connector.

- Measure the resistance of the wire harness side connector.

Standard resistance

Replace ecm

Pressure control solenoid "b" electrical (shift solenoid valve sl2)

Pressure control solenoid "b" electrical (shift solenoid valve sl2)

Description

Shifting from 1st to o/d is performed in combination with the on and off

operation of the shift solenoid

valves sl1 and sl2, which are controlled by the ecm. If an open or short ci ...

Shift solenoid "d" control circuit

Shift solenoid "d" control circuit

Description

Shifting from 1st to o/d is performed in combination with the on and off

operation of the shift solenoid

valves sl1 and sl2, which are controlled by the ecm. If an open or short ci ...

Other materials:

Room temperature sensor circuit

Description

The room temperature sensor is installed in the instrument panel to detect

the room temperature and

control the heater and air conditioner auto mode. The resistance of the room

temperature sensor

changes in accordance with the room temperature. As the temperature decreases,

...

Data list / active test

Read data list

Hint:

Using the intelligent tester's data list allows switch,

sensor, actuator and other item values to be read without

removing any parts. Reading the data list early in

troubleshooting is one way to save time.

Connect the intelligent tester (with can vim) to the

dlc3 ...

Terminals of ecm

Check ecm

Measure the voltage of the ecm connector.

Hint:

Each ecm terminal's standard voltage is shown in

the table below.

In the table, first follow the information under

"condition". Look under "symbols (terminal no.)"

For the terminals to be inspected. ...