Toyota RAV4 (XA40) 2013-2018 Service Manual: Problem symptoms table

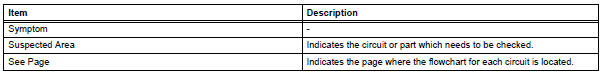

When a "normal" code is output during a dtc check but the problem is still occurring, use the problem symptoms table. The suspected areas (circuits or parts) for each problem symptom are in the table. The suspected areas are listed in order of probability. A description of each of the chart's columns is below.

Hint: in some cases, the problem is not detected by the diagnostic system even though a problem symptom is present. It is possible that the problem is occurring outside the detection range of the diagnostic system, or that the problem is occurring in a completely different system.

Diagnostic trouble code chart

Diagnostic trouble code chart

Look for output diagnostic trouble codes (dtcs) (from the

dtc checks) in the appropriate section's diagnostic trouble

code chart. Use the chart to determine the trouble area and

the proper inspecti ...

Circuit inspection

Circuit inspection

A description of the main areas of each circuit inspection

is below.

Item

Description

description

The major role, operation of the circuit and its component parts are

explai ...

Other materials:

Installation

Install fan and generator v belt

Using sst and 19 mm socket wrench, loosen the vribbed

belt tensioner arm clockwise, then install the

fan and generator v belt.

Sst 09216-42010

Notice:

Be sure to connect sst and the tools so that

they are in line during use.

When retracti ...

Trailer towing tips

Your vehicle will handle differently when towing a trailer. Help to avoid

an accident, death or serious injury, keep the following in mind when

towing:

Speed limits for towing a trailer vary by state or province. Do not

exceed the posted towing speed limit.

Toyota recommends that the vehic ...

Adjusting the position of and opening and closing the air outlets

Front center outlets

Direct air flow to the left or

right, up or down.

Turn the knobs to open or

close the vents.

Turn the knob to open or

close the vent for rear seat

occupants.

Đś

Direct air flow to the left or right,

up or down.

Open the vent.

Close the vent.

...