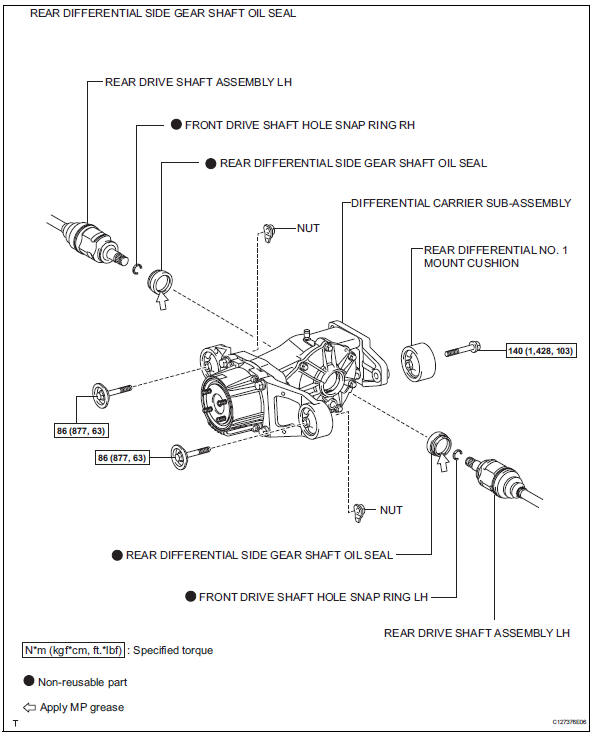

Toyota RAV4 (XA40) 2013-2018 Service Manual: Rear differential side gear shaft oil seal

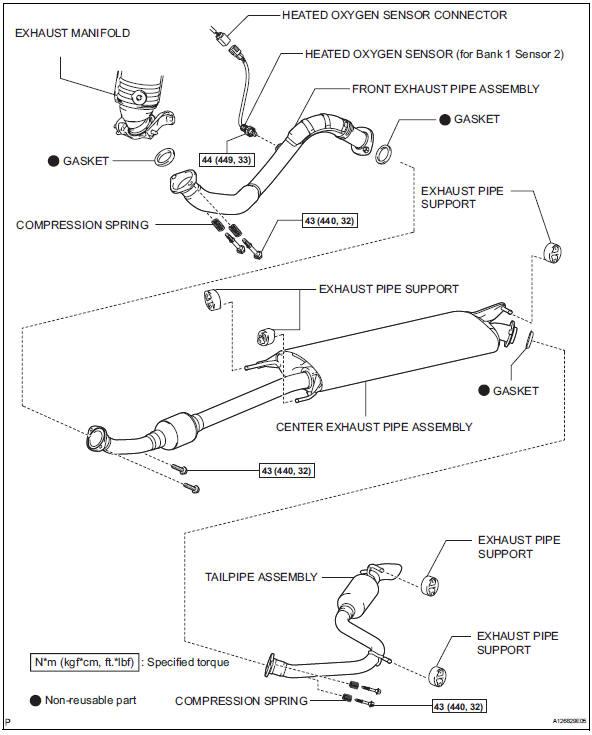

Components

Removal

- Drain differential oil (see page df-10)

- Remove tailpipe assembly

- Remove the tailpipe (see page ex-2).

- Remove center exhaust assembly

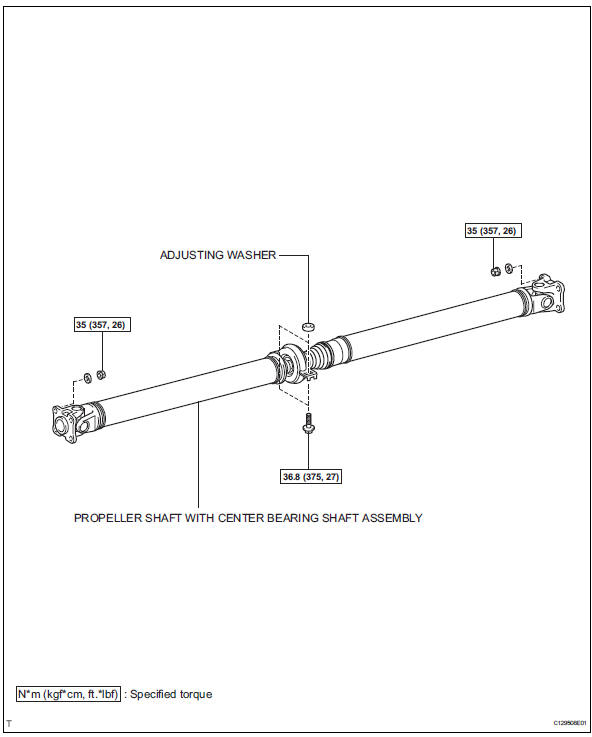

- Remove propeller with center bearing shaft assembly (see page pr-3)

- Remove rear differential carrier subassembly (see page df-18)

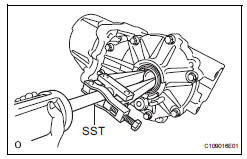

- Remove rear differential side gear shaft oil seal

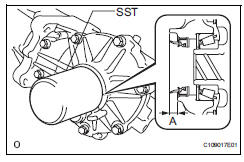

- Using a sst, tap out the 2 oil seals.

Sst 09308-00010

Installation

- Install rear differential side gear shaft oil seal

- Apply a light coat of mp grease to the lip of a new rear differential side gear shaft oil seal.

- Using sst and a hammer, tap the 2 rear differential side gear shaft oil seals into the rear differential carrier and differential side bearing retainer according to the specification.

Sst 09223-00010

Standard oil seal tapping amount (a value): 7.2 +-0.5 Mm (0.28 +-0.02 In.)

- Install rear differential carrier assembly (see page df-44)

- Temporarily install propeller with center bearing shaft assembly (see page pr-5)

- Tighten propeller with center bearing shaft assembly (see page pr-6)

- Inspect and adjust joint angle (see page pr- 4)

- Install center exhaust pipe assembly

- Install the center pipe (see page ex-5).

- Install tailpipe assembly

- Install the tailpipe (see page ex-6).

- Add differential oil

- Add differential oil (see page df-3).

- Check for differential oil leakage

- Check for exhaust gas leakage

If gas is leaking, tighten the areas necessary to stop the leak. Replace damaged parts as necessary.

Differential oil

Differential oil

On-vehicle inspection

Check differential oil

Stop the vehicle on a level surface.

Using a 10 mm socket hexagon wrench, remove the

rear differential filler plug and gasket.

...

Diaphragm oil seal

Diaphragm oil seal

Components

Removal

Drain differential oil

Using a 10 mm socket hexagon wrench, remove the

rear differential drain plug and gasket, and drain the

oil.

Install a new gasket to t ...

Other materials:

Towing related terms

Gcwr (gross combination weight rating)

The maximum allowable gross

combination weight. The gross

combination weight is the sum

of the total vehicle weight

(including the occupants, cargo

and any optional equipment

installed on the vehicle) and the

weight of the trailer being towed

(inc ...

If the shift lever cannot

be shifted from p

If the shift lever cannot be shifted with your foot on the brake

pedal, there may be a problem with the shift lock system (a system

to prevent accidental operation of the shift lever). Have the

vehicle inspected by your toyota dealer immediately.

The following steps may be used as an emergency ...

Diagnosis system

Bus check

Select "bus check" from the "obd / mobd

menu" screen.

Hint:

The ecus and sensors that are properly connected

to the can communication system can be displayed

using the intelligent tester via can vim.

Press "enter" on the intelligen ...