Toyota RAV4 (XA40) 2013-2018 Service Manual: Evaporative emission system reference orifice

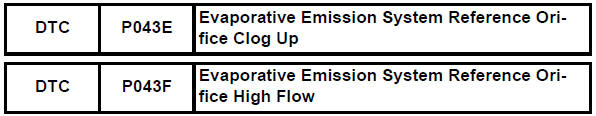

Dtc summary

Hint:

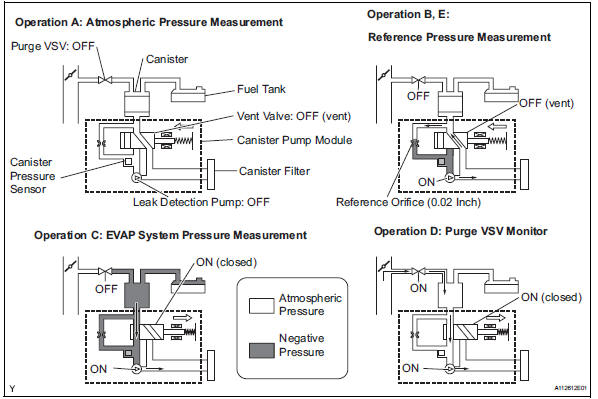

The reference orifice is located inside the canister pump module.

Description

The description can be found in the evap (evaporative emission) system (see page es-335).

Inspection procedure

Refer to the evap system (see page es-340).

Monitor description

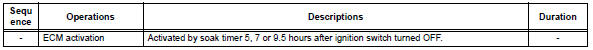

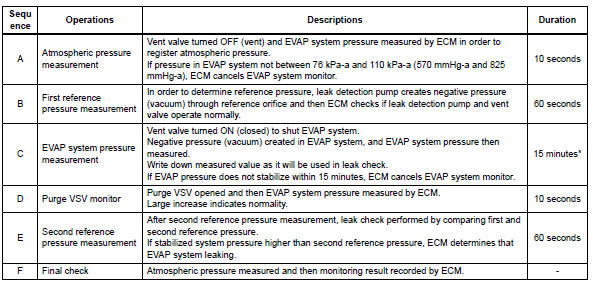

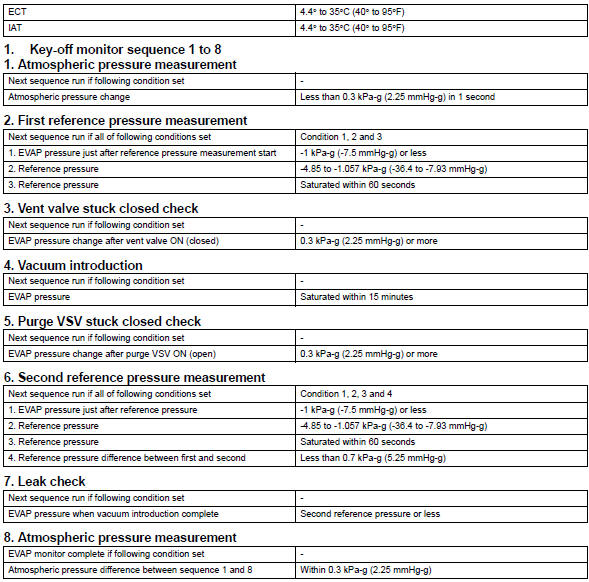

5 Hours* after the ignition switch is turned off, the leak detection pump creates negative pressure (vacuum) in the evap system. The ecm monitors for leaks and actuator malfunctions based on the evap pressure.

Hint:

*: If the engine coolant temperature is not below 35°c (95°f) 5 hours after the ignition switch is turned off, the monitor check starts 2 hours later. If it is still not below 35°c (95°f) 7 hours after the ignition switch is turned off, the monitor check starts 2.5 Hours later.

*: If only a small amount of fuel is in the fuel tank, it takes longer for the evap pressure to stabilize.

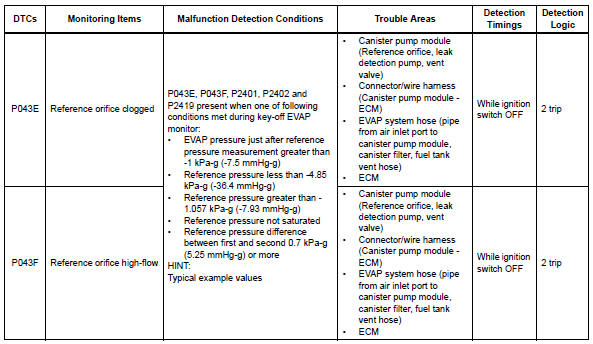

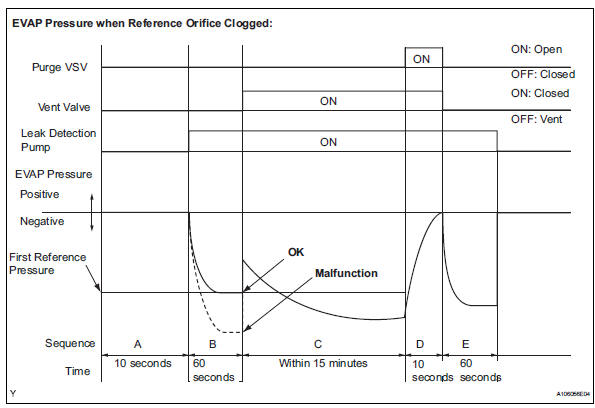

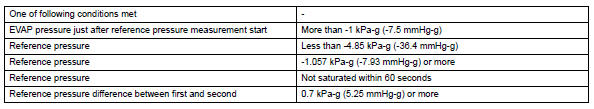

- P043e: reference orifice clogged

In operation b, the leak detection pump creates negative pressure (vacuum) through the reference orifice.

The evap system pressure is then measured by the ecm, using the canister pressure sensor, to determine the reference pressure. If the pressure is lower than -4.85 Kpa-g (-36.4 Mmhg-g), the ecm interprets this as a clog malfunction in the reference orifice, and stops the evap system monitor.

The ecm then illuminates the mil and sets the dtc (2 trip detection logic).

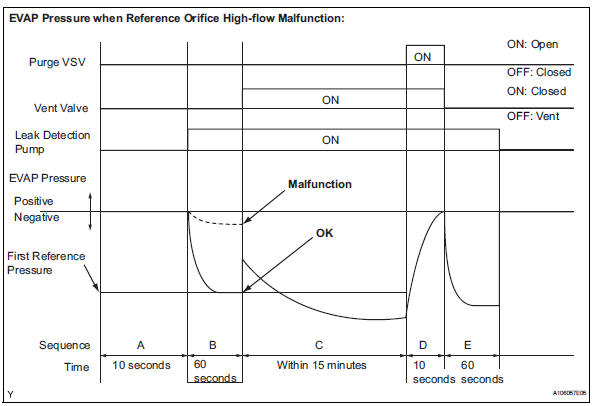

- P043f: reference orifice high-flow

In operation b, the leak detection pump creates negative pressure (vacuum) through the reference orifice.

The evap system pressure is then measured by the ecm using the canister pressure sensor to determine the reference pressure. If the pressure is higher than -1.057 Kpa-g (-7.93 Mmhg-g), the ecm interprets this as a high-flow malfunction in the reference orifice, and stops the evap system monitor. The ecm then illuminates the mil and sets the dtc (2 trip detection logic).

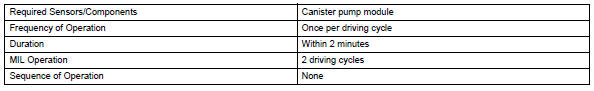

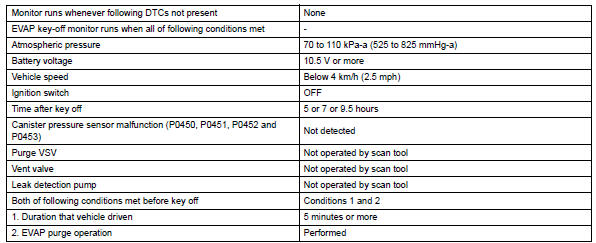

Monitor strategy

Typical enabling conditions

Typical malfunction thresholds

"Saturated" indicates that the evap pressure change is less than 0.286 Kpa-g (2.14 Mmhg-g) in 60 seconds.

Monitor result

Refer to checking monitor status (see page es-17).

Catalyst system efficiency below threshold (bank 1)

Catalyst system efficiency below threshold (bank 1)

Monitor description

The ecm uses sensors mounted in front of and behind the three-way catalytic

converter (twc) to

monitor its efficiency.

The first sensor, the air-fuel ratio (a/f) sensor, ...

Evaporative emission control system incorrect purge flow

Evaporative emission control system incorrect purge flow

Dtc summary

Description

The description can be found in the evap (evaporative emission) system (see

page es-335).

Inspection procedure

Refer to the evap system (see page es-340).

Monito ...

Other materials:

Removal

Hint:

Use the same procedures for the lh side and rh side.

The procedures listed below are for the lh side.

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and ...

Customization

Customizable features

Your vehicle includes a variety of electronic features that can be

personalized to your preferences. The settings of these features

can be changed by using the steering wheel switches, entune

premium audio with navigation or entune audio, or at your

toyota dealer.

Customi ...

Sensor (motor) failure

Description

When the sliding roof drive gear (sliding roof ecu) detects the motor's

malfunction, and the sliding roof

operation is stopped, dtc b2341 is output. When the sliding roof drive gear

(sliding roof ecu) detects the

gear's malfunction, and the sliding roof operation is stopped, d ...