Toyota RAV4 (XA40) 2013-2018 Service Manual: Transmission range sensor circuit malfunction (prndl input)

Description

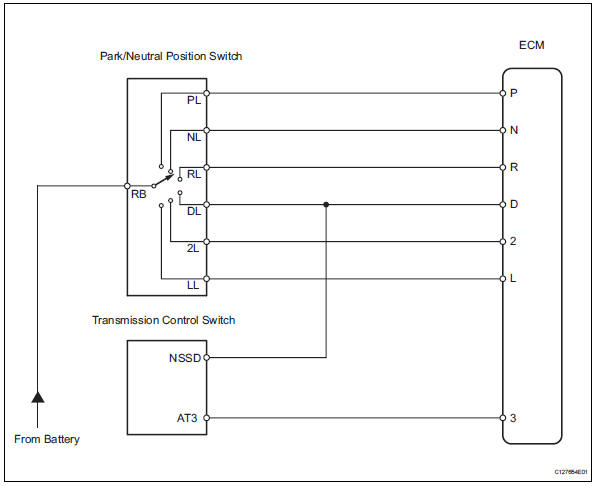

The park/neutral position (pnp) switch detects the shift lever position and sends signals to the ecm.

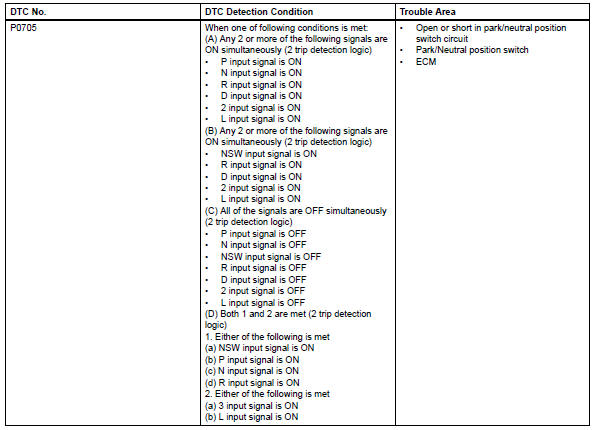

Monitor description

These dtcs indicate a problem with the park/neutral position switch and the wire harness in the park/ neutral position switch circuit.

The park/neutral position switch detects the shift lever position and sends a signal to the ecm.

For security, the park/neutral position switch detects the shift lever position so that the engine can be started only when the shift lever is on p or n.

The park/neutral position switch sends a signal to the ecm according to the shift lever position (r, d, 3, 2 or l).

The ecm determines that there is a problem with the switch or related parts if it receives more than 1 position signal simultaneously. The ecm will illuminate the mil and store the dtc.

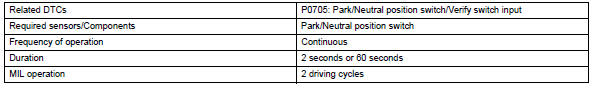

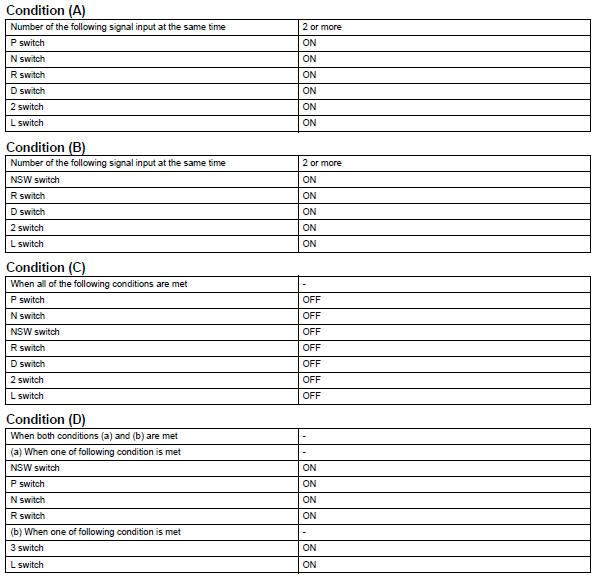

Monitor strategy

![]()

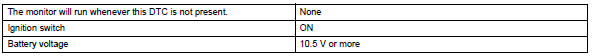

Typical enabling conditions

Typical malfunction thresholds

Component operating range

![]()

Wiring diagram

Inspection procedure

Hint:

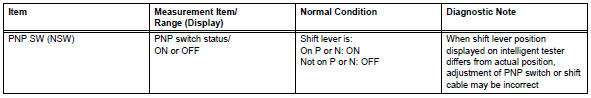

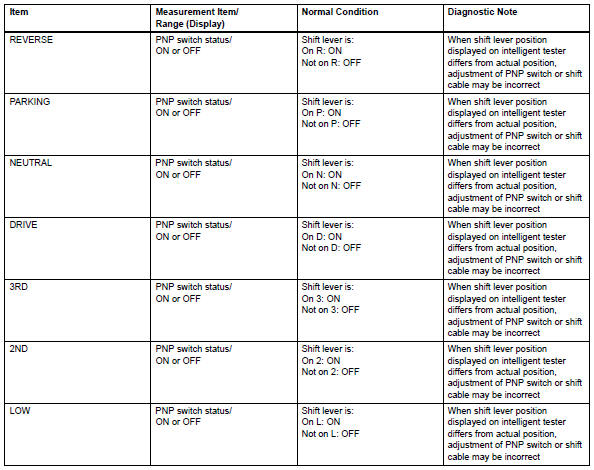

Using the intelligent tester's data list allows switch, sensor, actuator and other item values to be read without removing any parts. Reading the data list early in troubleshooting is one way to save time.

Notice:

In the table below, the values listed under "normal condition" are reference values. Do not depend solely on these reference values when deciding whether a part is faulty or not.

- Warm up the engine.

- Turn the ignition switch off.

- Connect the intelligent tester to the can vim. Then connect the can vim to the dlc3.

- Turn the ignition switch on and turn the tester on.

- Enter the following menus: diagnosis / enhanced obd ii / data list.

- Follow the instructions on the tester and read the data list.

- Check wire harness (park/neutral position switch - battery)

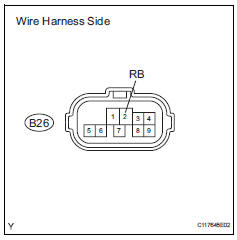

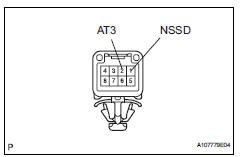

- Disconnect the b26 park/neutral position switch connector.

- Turn the ignition switch on.

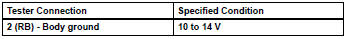

- Measure the voltage.

Standard voltage

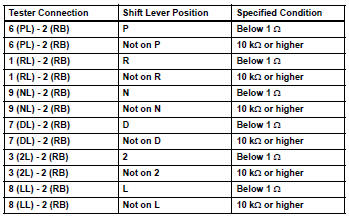

- Inspect park/neutral position switch

- Disconnect the b26 park/neutral position switch connector.

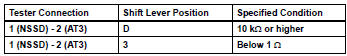

- Measure the resistance of the park/neutral position switch when the shift lever is moved to each position.

Standard resistance

- Check wire harness (ecm - battery and body ground)

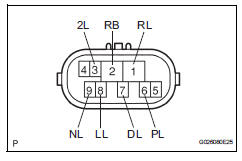

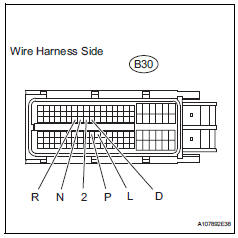

- Disconnect the b30 ecm connector.

- Turn the ignition switch on.

- Measure the voltage of the wire harness side connector.

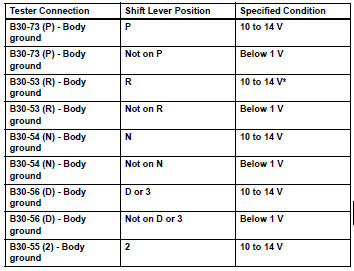

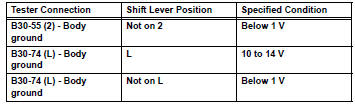

Standard voltage

Hint:

*: The voltage will drop slightly due to the illumination of the back-up light.

- Check wire harness (park/neutral position switch - transmission control switch)

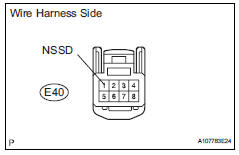

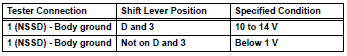

- Disconnect the e40 switch connector.

- Turn the ignition switch on.

- Measure the voltage when the shift lever is moved to each position.

Standard voltage

- Inspect transmission control switch

- Disconnect the e40 switch connector.

- Measure the resistance of the switch when the shift lever is moved to each position.

Standard resistance

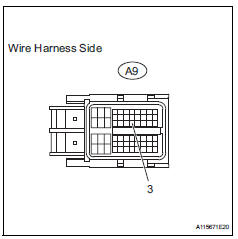

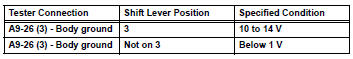

- Check wire harness (transmission control switch - battery and body ground)

- Disconnect the a9 ecm connector.

- Turn the ignition switch on.

- Measure the voltage of the wire harness side connector.

Standard voltage

Hint:

*: The voltage will drop slightly due to the illumination of the back-up light.

Diagnostic trouble code chart

Diagnostic trouble code chart

If a dtc is displayed during the dtc check, check the circuit

listed in the table below and proceed to the page given.

Hint:

*1: "Comes on" means the malfunction indicator lamp

(mil) ...

Transmission fluid temperature sensor "A" circuit

Transmission fluid temperature sensor "A" circuit

Description

The automatic transmission fluid (atf) temperature sensor converts the atf

temperature into a

resistance value which is input into the ecm.

The ecm applies a voltage to the temp ...

Other materials:

Data list / active test

Read data list

Hint:

Using the intelligent tester's data list allows switch,

sensor, actuator and other item values to be read without

removing any parts. Reading the data list early in

troubleshooting is one way to save time.

Connect the intelligent tester to the dlc3.

Turn the igni ...

Data list / active test

Read data list

Hint:

Using the intelligent tester's data list allows switch,

sensor, actuator and other item values to be read without

removing any parts. Reading the data list early in

troubleshooting is one way to save time.

Connect the intelligent tester (with can vim) to the

dlc3 ...

Abnormal temperature inside

Description

The tire pressure warning valve and transmitter measures tire internal

temperature as well as tire

pressure, and transmits the information to the tire pressure monitor receiver

along with the transmitter id.

If the measured temperature is out of the specified range, the tire ...