Toyota RAV4 (XA40) 2013-2018 Service Manual: Valve body

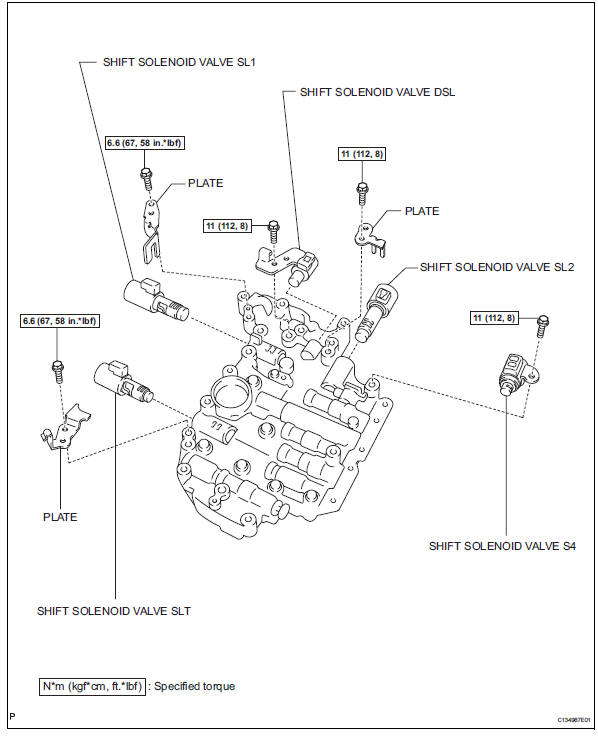

Components

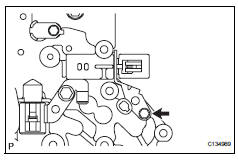

Disassembly

- Remove shift solenoid valve slt

- Remove the bolt, plate and shift solenoid valve slt from the valve body.

- Remove shift solenoid valve sl1

- Remove the bolt, plate and shift solenoid valve sl1 from the valve body.

- Remove shift solenoid valve dsl

- Remove the bolt and shift solenoid valve dsl from the valve body.

- Remove shift solenoid valve sl2

- Remove the bolt, plate and shift solenoid valve sl2 from the valve body.

- Remove shift solenoid valve s4

- Remove the bolt and shift solenoid valve s4 from the valve body.

- Remove manual valve

- Remove the manual valve from the valve body.

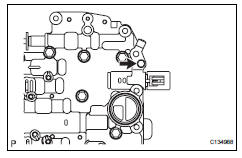

Reassembly

- Install manual valve

- Install the manual valve to the valve body.

- Install shift solenoid valve s4

- Install the shift solenoid valve s4 to the valve body with the bolt.

Torque: 11 n*m (112 kgf*cm, 9 ft.*Lbf)

- Install shift solenoid valve sl2

- Install the shift solenoid valve sl2 to the valve body with the bolt and plate.

Torque: 11 n*m (112 kgf*cm, 8 ft.*Lbf)

- Install shift solenoid valve dsl

- Install the shift solenoid valve dsl to the valve body with the bolt.

Torque: 11 n*m (112 kgf*cm, 8 ft.*Lbf)

- Install shift solenoid valve sl1

- Install the shift solenoid valve sl1 to the valve body with the bolt and plate.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*Lbf)

- Install shift solenoid valve slt

- Install the shift solenoid valve slt to the valve body with the bolt and plate.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*Lbf)

Underdrive clutch

Underdrive clutch

Components

Disassembly

Inspect pack clearance of underdrive

clutch (see page ax-247)

Remove no. 1 Underdrive clutch disc

Using a screwdriver, pry out the underdrive clutch

fla ...

Differential case

Differential case

Components

Disassembly

Remove front differential ring gear

Place the matchmarks on the ring gear and

differential case.

Remove the 14 bolts.

Using a plastic-fa ...

Other materials:

Power outlet socket

Components

Removal

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

Remove switch base (see page ip-21)

Remove power o ...

Diagnosis system

Description

When troubleshooting obd ii (on-board diagnostics)

vehicles, the intelligent tester (complying with sae

j1987) must be connected to the dlc3 (data link

connector 3) of the vehicle. Various data in the vehicle's

ecm (engine control module) can be then read.

Obd ii regulations ...

Fuel pump shut off

system

To minimize the risk of fuel leakage when the engine stalls or

when an airbag inflates upon collision, the fuel pump shut off

system stops the supply of fuel to the engine.

Follow the procedure below to restart the engine after the system is

activated.

Vehicles without a smart key system

Tu ...