Toyota RAV4 (XA40) 2013-2018 Service Manual: Basic inspection

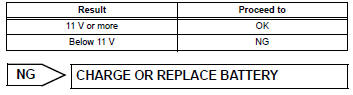

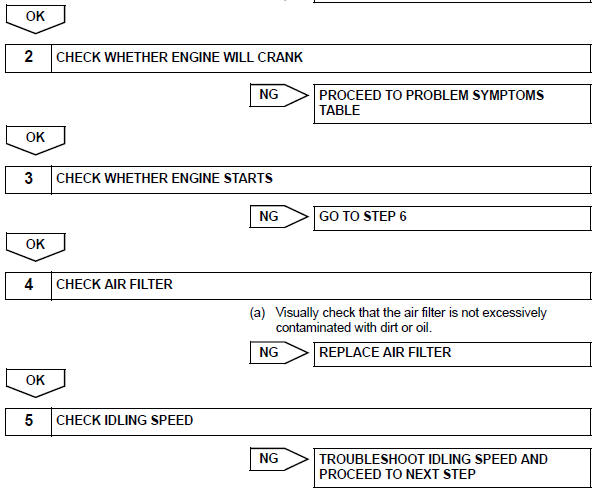

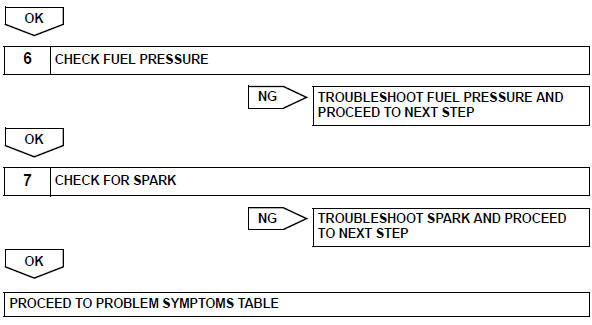

When a malfunction is not confirmed by the dtc check, troubleshooting should be carried out in all circuits considered to be possible causes of the problem. In many cases, by carrying out the basic engine check shown in the following flowchart, the location of the problem can be found quickly and efficiently. Therefore, using this check is essential when engine troubleshooting.

![]()

Notice:

Conduct this check with the engine stopped and ignition

switch off.

Check for intermittent problems

Check for intermittent problems

Hint:

Inspect the vehicle's ecm using check mode. Intermittent

problems are easier to detect with the intelligent tester when

the ecm is in check mode. In check mode, the ecm uses 1

trip detection ...

Registration

Registration

Notice:

The vehicle identification number (vin) must be input

into the replacement ecm.

Hint:

The vin is a 17-digit alphanumeric number. The intelligent

tester is required to register the vin.

...

Other materials:

Rear no. 1 Suspension arm

Components

Removal

Hint:

Use the same procedures for the rh side and lh side.

The procedures listed below are for the lh side.

Remove rear wheel

Remove rear no. 1 Suspension arm assembly lh

Support the no. 2 Suspension arm lh.

Remove the bolt and 2 nuts from t ...

Adjusting the mirrors

Make sure that you can see backward clearly by adjusting the inside

and outside rear view mirrors properly.

Caution

Observe the following precautions.

Failure to do so may result in death or serious injury.

Do not adjust the position of the driver’s seat while driving.

Doing so could ...

Antenna location and effective range

Antenna location

Antennas outside the cabin

Antennas inside the cabin

Antenna outside the luggage

compartment

Effective range (areas within which the electronic key is

detected)

When locking or unlocking

the doors

The system can be operated

when the electronic key is with ...