Toyota RAV4 (XA40) 2013-2018 Service Manual: Fuel pump

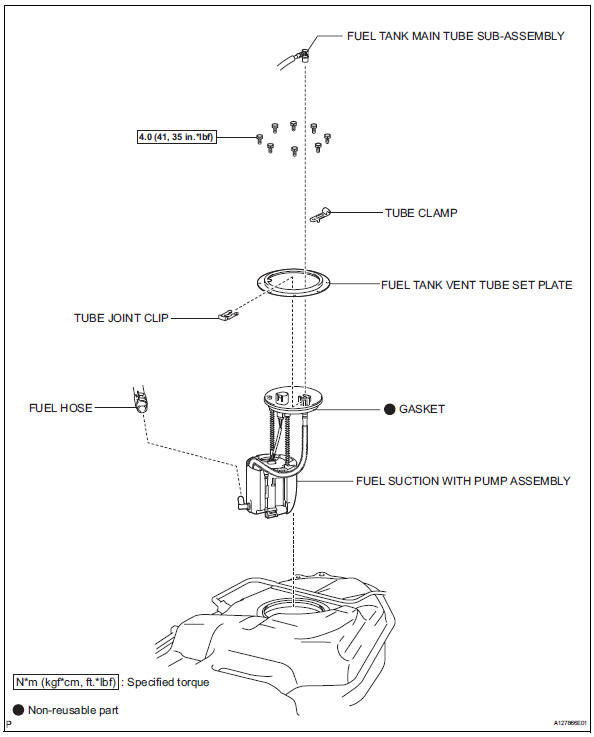

Components

Removal

- Remove fuel tank assembly

- Remove the fuel tank (see page fu-39).

- Remove fuel tank main tube sub-assembly

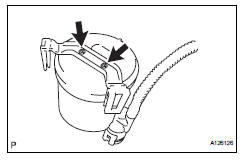

- Remove the joint clip and fuel tank main tube.

Caution:

- Before removing the tube joint clip, check for foreign matter around the clip. Clean if necessary.

- Keep the o-ring free of foreign matter, as it becomes contaminated easily.

- Do not use any tools in this procedure.

- Do not forcefully bend or twist the tube.

- Put the tube in a plastic bag to prevent damage and contamination.

- If the fuel suction plate and tube are stuck together, pinch the tube and turn it carefully to disconnect it.

- Be careful not to damage the clip. If the clip is damaged, replace it.

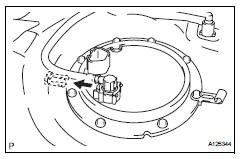

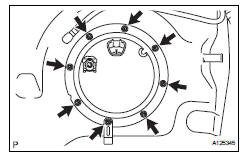

- Remove fuel tank vent tube set plate

- Remove the 8 bolts and set plate.

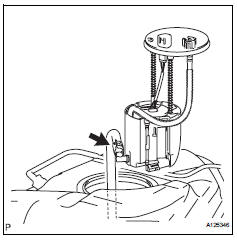

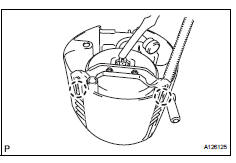

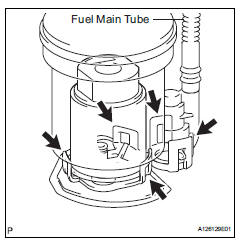

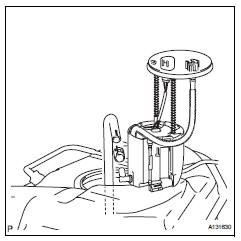

- Remove fuel suction with pump assembly

- Disconnect the fuel hose and remove the fuel pump from the fuel tank.

Notice:

Do not damage the fuel pump.

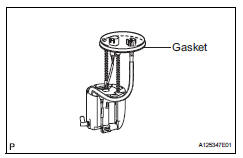

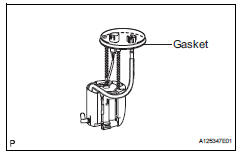

- Remove the gasket from the fuel pump.

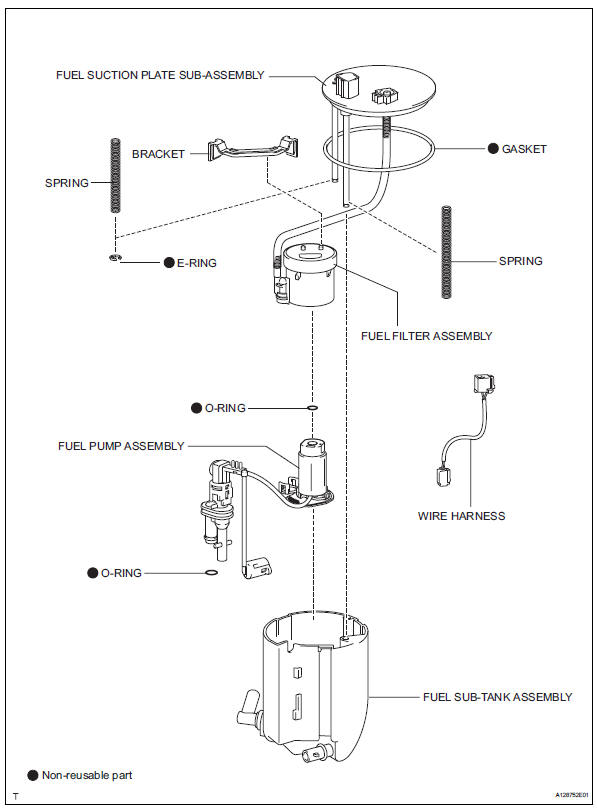

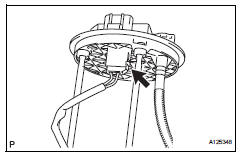

- Remove fuel sub-tank assembly

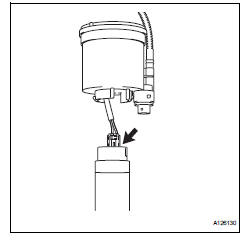

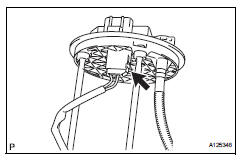

- disconnect the wire harness.

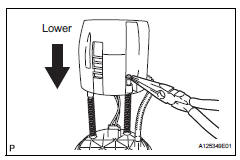

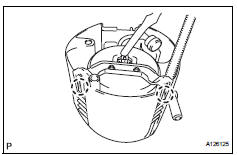

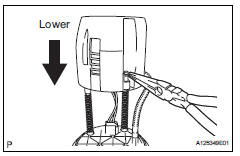

- Using needle nose pliers, remove the e-ring.

Hint:

Slightly lower the sub-tank to remove the e-ring.

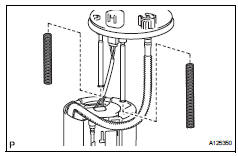

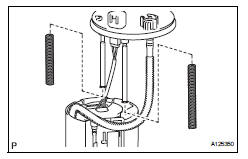

- Remove the 2 springs from the 2 shaft.

- Remove the 2 springs from the 2 shaft.

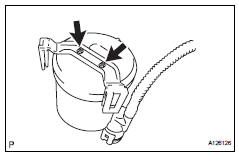

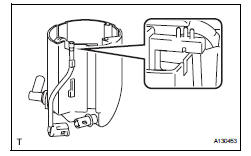

- Detach the 2 claws and remove the sub-tank.

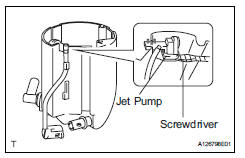

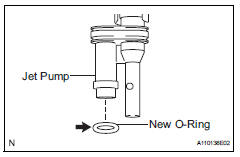

- Disengage the claw of the jet pump nozzle.

- Using a screwdriver with the tip taped, remove the jet pump.

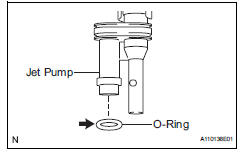

- Remove the o-ring from the jet pump.

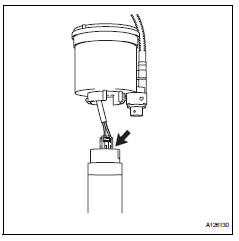

- Remove bracket

- Using a screwdriver, detach the 2 claws and remove the bracket.

Hint:

Tape the screwdriver tip before use.

- Remove fuel pump assembly

- Detach the 5 claws on the filter and remove the fuel pump from the fuel filter.

Hint:

When removing the claw, do not disconnect the fuel main tube.

- Disconnect the fuel pump connector.

- Remove the o-ring from the fuel filter.

Inspection

- Inspect fuel pump

- Check the fuel pump resistance.

- Measure the resistance between terminals 1 and 2.

Standard resistance: 0.2 To 3.0 ٠at 20°c (68°f)

If the result is not as specified, replace the fuel pump.

- Check fuel pump operation.

- Apply battery voltage to terminals 1 and 2.

Check that the pump operates.

Notice:

- These tests must be completed within 10 seconds to prevent the coil from burning out.

- Keep the fuel pump as far away from the battery as possible.

- Always the voltage on and off on the battery side, not the fuel pump side.

If the pump does not operate, replace the fuel pump.

Installation

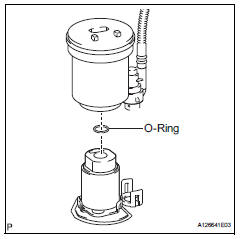

- Install fuel pump assembly

- Connect the pump harness connector.

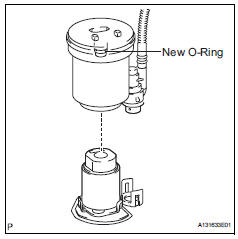

- Apply gasoline to a new o-ring and install the o-ring to the fuel filter.

- Attach the 5 claws to the claw holes and install the fuel pump.

- Install bracket

- Attach the 2 claws to the claw holes and install the bracket.

- Install fuel sub-tank assembly

- Apply gasoline to a new o-ring and install it to the jet pump.

- Install the jet pump while aligning it to the installation position of the sub-tank.

- Install the jet pump nozzle.

- Attach the 2 claws to the claw holes and install the fuel sub-tank.

- Connect the wire harness.

- Install the spring to the fuel suction plate shaft and install them to the sub-tank.

- Using needle-nose pliers, install a new e-ring.

Hint:

Slightly lower the sub-tank to install the e-ring.

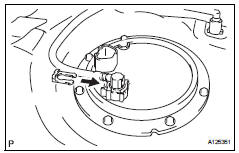

- Install fuel suction with pump assembly

- Install a new gasket onto the fuel pump.

Connect the fuel hose and install the fuel pump into the fuel tank.

Notice:

Do not damage the fuel pump filter.

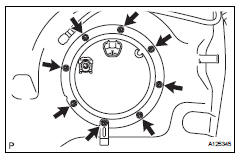

- Install fuel tank vent tube set plate

- Install the set plate with the 8 bolts.

Torque: 4.0 N*m (41 kgf*cm, 35 in.*Lbf)

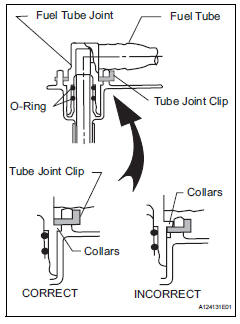

- Install fuel tank main tube sub-assembly

- Install the fuel tube with the joint clips.

Caution:

- Check that there are no scratches or foreign objects on the connecting parts.

- Check that the fuel tube joint is inserted securely.

- Check that the fuel tube joint clip is on the collars of the fuel tube joint.

- After installing the tube joint clip, check that the fuel tube joint has not been pulled off.

- Be careful not to damage the clip. If the clip is damaged, replace it.

Install fuel tank assembly

- Install the fuel tank (see page fu-44).

Fuel pressure pulsation damper

Fuel pressure pulsation damper

Components

Removal

Discharge fuel system pressure (see page

fu-9)

Disconnect cable from negative battery

terminal

Remove no. 1 Engine cover (see page es-410)

Remove air cleaner ...

Fuel tank

Fuel tank

Components

Removal

Discharge fuel system pressure (see page

fu-9)

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cabl ...

Other materials:

Removal

Drain engine coolant (see page co-6)

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

Remove air cleaner cap (see page es-41 ...

Automatic transmission

Select the shift position

depending on your purpose

and situation.

Shift position purpose

and functions

P - Parking the vehicle/

starting the engine

R - Reversing

N - Neutral

D - Normal driving*1

S - S mode driving*2

*1:Shifting to the D position allows

the system to select a gear suitable

for ...

System description

System description

Hint:

The skid control ecu forms a single unit with the abs

and traction actuator.

Abs (anti-lock brake system):

the abs helps prevent the wheels from locking

when the brakes are applied firmly or on a slippery

surface.

Operation description:

the skid ...