Toyota RAV4 (XA40) 2013-2018 Service Manual: Inspection

- Inspect starter assembly

Notice:

These tests must be performed within 3 to 5 seconds to avoid burning out the coil.

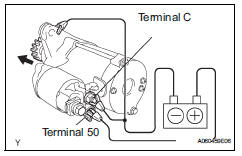

- Perform the pull-in test.

- Disconnect the lead wire from terminal c.

- Connect the battery to the magnetic switch as

shown in the illustration. Check that the clutch

pinion gear extends.

If the clutch pinion gear does not move, replace the magnetic switch.

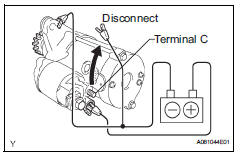

- Perform the hold-in test.

- Maintain the battery connections of the pull-in

test above, but disconnect the negative (-) lead

from terminal c. Check that the pinion gear

remains extended.

If the clutch pinion gear returns inward, replace the magnetic switch.

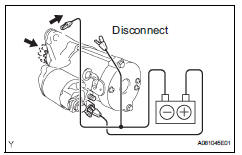

- Check the clutch pinion gear return.

- Disconnect the negative (-) lead from the

switch body. Check that the clutch pinion gear

returns.

If the clutch pinion gear does not return, replace the magnetic switch.

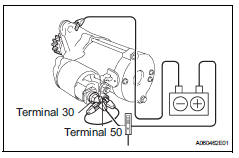

- Perform the no-load performance test.

- Connect the lead wire to terminal c. Make sure that the lead is not grounded.

- Clamp the starter in a vise.

- Connect the battery and an ammeter to the starter as shown in the illustration.

- Check that the starter rotates smoothly and

steadily while the pinion gear is moving out.

Then measure the current.

Standard current: 90 a or less at 11.5 V

If result is not as specified, replace the starter assembly.

- Inspect magnetic switch assembly

- Check the plunger.

- Push in the plunger and check that it returns

quickly to its original position.

If necessary, replace the magnetic switch assembly.

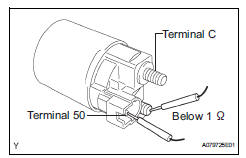

- Check if the pull-in coil has an open circuit.

- Measure the resistance between terminals 50 and c.

Standard resistance:

below 1

If the result is not as specified, replace the magnetic switch assembly.

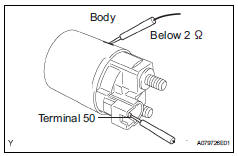

- Check if the hold-in coil has an open circuit.

- Measure the resistance between terminal 50 and the switch body.

Standard resistance:

below 2

If the result is not as specified, replace the magnetic switch assembly.

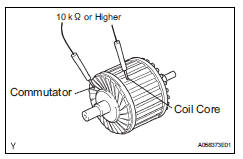

- Inspect starter armature assembly

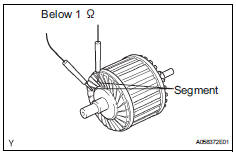

- Check if the commutator has an open circuit.

- Measure the resistance between the segments of the commutator.

Standard resistance:

below 1

If the result is not as specified, replace the armature assembly.

- Check if the commutator is grounded.

- Measure the resistance between the commutator and armature coil core.

Standard resistance:

10 k or higher

or higher

If the result is not as specified, replace the armature assembly

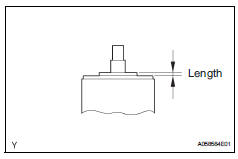

- Check the commutator for contamination and burns

on its surface.

If the surface is dirty or burnt, correct it with sandpaper (no. 400) Or a lathe

- Using a vernier caliper, measure the commutator's length.

Standard length: 3.1 To 3.8 Mm (0.122 To 0.150 In.)

If the length is greater than the maximum, replace the starter armature assembly.

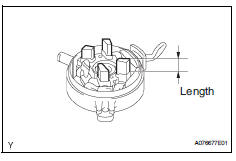

- Inspect starter commutator end frame assembly

- Using a vernier caliper, measure the brush length.

Standard length: 4.0 To 9.0 Mm (0.158 To 0.359 In.)

If the length is less than the minimum, replace the end frame assembly.

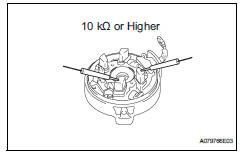

- Check the brush insulation.

- Measure the resistance between the positive (+) and negative (-) brush.

Standard resistance:

10 k or higher

or higher

If the result is not as specified, repair or replace the end frame assembly.

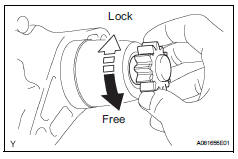

- Inspect starter clutch

- Check the starter clutch.

- Rotate the clutch pinion gear counterclockwise

and check that it turns freely. Try to rotate the

clutch pinion gear clockwise and check that it

locks.

If necessary, replace the starter drive housing assembly.

Disassembly

Disassembly

Remove magnetic switch assembly

Remove the nut and disconnect the lead wire from

the magnetic switch.

Remove the 2 screws holding the magnetic switch

to the starter drive housin ...

Reassembly

Reassembly

Hint:

Use high-temperature grease to lubricate the bearings,

gears, return spring and steel ball when assembling the

starter.

Install planetary gear

Apply grease to the planetary gears an ...

Other materials:

Dtc check / clear

Check dtc (using sst (check wire))

Check the dtcs (present trouble code).

Turn the ignition switch on, and wait for

approximately 60 seconds.

Using sst, connect terminals 13(tc) and 4(cg)

of the dlc3.

Sst 09843-18040

Notice:

Connect the terminals to the correct

positio ...

Wireless remote control

The keys are equipped with the

following wireless remote control:

Vehicles without smart key

system

Locks all the doors

Sounds the alarm

Unlocks all the doors

Opens the side windows*

*: This setting must be customized

at your Toyota dealer.

Vehicles with smart key system

Locks all the do ...

Tire pressure warning valve and transmitter

Components

Removal

Remove front tire

Remove rear tire

Remove tire pressure warning valve subassembly

Remove the valve core and cap, and release air

from the tire.

After ensuring that air is sufficiently released,

remove the nut and washer that are used to fix the

tire pres ...