Toyota RAV4 (XA40) 2013-2018 Service Manual: Installation

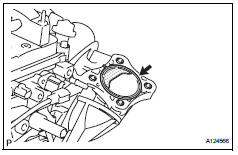

- Install throttle body

- Install a new gasket onto the intake manifold.

- Install the throttle body and fuel pipe clamp with the 4 bolts.

Torque: 30 n*m (305 kgf*cm, 22 ft.*Lbf)

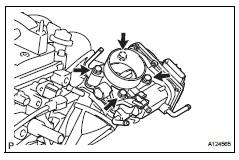

- Connect the fuel tube into the clamp.

- Connect the wire harness clamp.

- Connect the throttle position sensor and control motor connector.

- Connect the no. 1 Throttle body hose to the throttle body

- Connect the no. 2 Water by-pass hose to the throttle body.

- Connect the water by-pass hose to the throttle body.

- Connect the purge line hose to the throttle body.

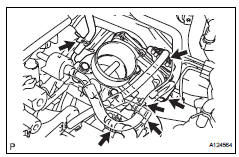

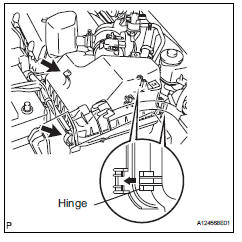

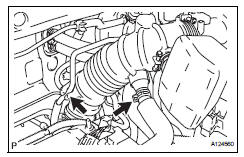

- Install air cleaner cap

- Install the air cleaner filter element onto the air cleaner case.

- Insert the hinge part of the air cleaner cap into the air cleaner case, then hang the 2 hook clamps.

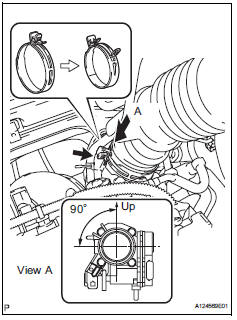

- Align the matchmarks of the no. 1 Air cleaner hose

and throttle body, and then connect the air cleaner

hose no. 1 To the throttle body and unfasten the no.

1 Air cleaner hose clamp.

Notice:

Make sure that the hose clamp is at the correct angle.

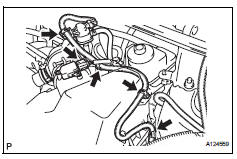

- Connect the purge line hose to the clamp.

- Connect the no. 2 Ventilation hose to the air cleaner hose.

- Install the 4 wire harness clamps.

- Connect the mass air flow meter connector.

- Connect cable to negative battery terminal

- Add engine coolant (see page co-6)

- Check for engine coolant leakage (see page co-1)

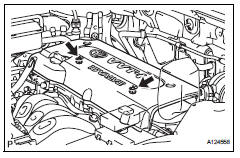

- Install no. 1 Engine cover

- Install the cover with the 2 nuts.

Torque: 7.0 N*m (71 kgf*cm, 62 in.*Lbf)

Inspection

Inspection

Inspect throttle body

Measure the resistance of the throttle control motor.

Standard resistance

If the result is not as specified, replace the throttle

body. ...

Knock sensor

Knock sensor

...

Other materials:

Problem symptoms table

Hint:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "suspected area"

column of the table. Check each symptom by checking the

suspected areas in the order they are listed. Re ...

Diagnosis system

Check dlc3

Check the dlc3:

the power steering ecu uses can (iso11898-1)

and iso9141-2 for communication protocol. The

terminal arrangement of the dlc3 complies with

sae j1962 and matches the iso9141-2 format.

Notice:

*: Before measuring the resistance, leave the

vehicle ...

System voltage

Description

The battery supplies electricity to the ecm even when the ignition switch is

in the off position. This

power allows the ecm to store data such as dtc history, freeze frame data and

fuel trim values. If the

battery voltage falls below a minimum level, the memory is cleared and ...