Toyota RAV4 (XA40) 2013-2018 Service Manual: Intake air temperature sensor gradient too high

Description

The intake air temperature (iat) sensor, mounted on the mass air flow (maf) meter, monitors the iat.

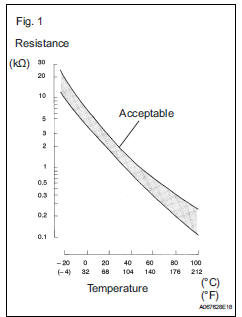

The iat sensor has a built-in thermistor with a resistance that varies according to the temperature of the intake air. When the iat is low, the resistance of the thermistor increases. When the temperature is high, the resistance drops. These variations in resistance are transmitted to the ecm as voltage changes (see fig. 1).

The iat sensor is powered by a 5 v supply from the tha terminal of the ecm, via resistor r.

Resistor r and the iat sensor are connected in series. When the resistance value of the iat sensor changes, according to changes in the iat, the voltage at terminal tha also varies. Based on this signal, the ecm increases the fuel injection volume when the engine is cold to improve driveability.

Monitor description

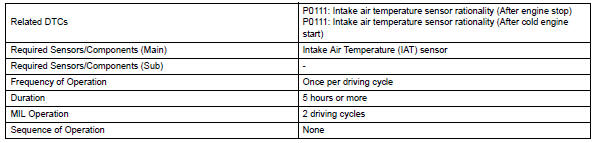

The ecm performs obd ii monitoring based on the values from the intake air temperature sensor. If there is no change of the sensor value within the normal range, the ecm will not be able to perform obd ii monitoring or will misdiagnose that there is a malfunction in the sensor. The ecm detects the stuck intake air temperature sensor value by performing monitoring after the ignition switch is turned off or the engine is started (short soak or long soak).

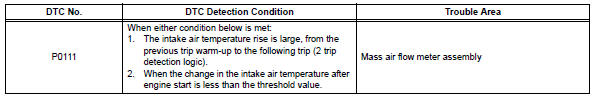

Monitor strategy

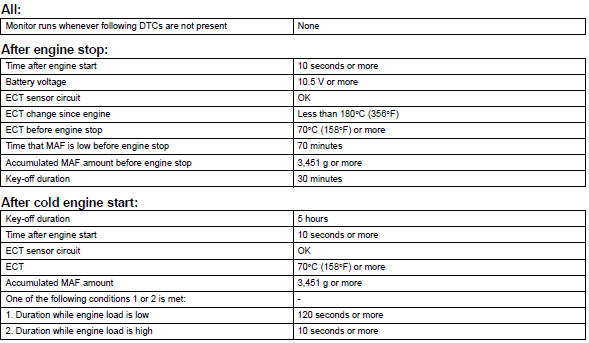

Typical enabling conditions

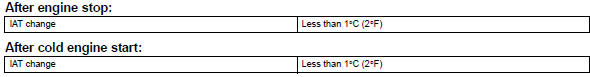

Typical malfunction thresholds

Wiring diagram

Refer to dtc p0110 (see page es-88).

Inspection procedure

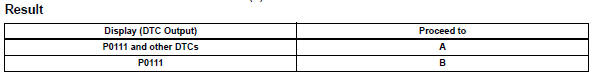

- Check any other dtcs output (in addition to dtc p0111)

- Connect the intelligent tester to the dlc3.

- Turn the ignition switch on.

- Turn the tester on.

- Enter the following menus: diagnosis / enhanced obd ii / dtc info / current codes.

- Read dtcs.

Hint:

If any dtcs other than p0111 are output, troubleshoot those dtcs first.

Intake air temperature circuit malfunction

Intake air temperature circuit malfunction

Description

The intake air temperature (iat) sensor, mounted on the mass air flow (maf)

meter, monitors the iat.

The iat sensor has a built-in thermistor with a resistance that varies ac ...

Engine coolant temperature circuit

Engine coolant temperature circuit

Description

A thermistor, whose resistance value varies according to the ect, is built

into the engine coolant

temperature (ect) sensor.

The structure of the sensor and its connection to th ...

Other materials:

Using the cd player

Power

Volume

Cd eject

Selecting a track or displaying

track list

Searching playback

Random play or back button

Repeat play

Fast-forwarding or rewinding

Changing the audio source/

playback

Playback/pause

Selecting a track

Displaying text message

Loading cds

Insert ...

On-vehicle inspection

Hint:

When pressing the switch for 0.3 Seconds or less, the roof

glass moves but auto operation does not operate.

Check auto operation

Turn the ignition switch on.

When the roof glass is fully closed, press the slide

open switch for 0.3 Seconds or more. Check that

the roof glass au ...

Srs airbags

The srs airbags inflate when the vehicle is subjected to certain

types of severe impacts that may cause significant injury to the

occupants. They work together with the seat belts to help reduce

the risk of death or serious injury.

Srs front airbags

Srs driver airbag/front passenger airb ...