Toyota RAV4 (XA40) 2013-2018 Service Manual: Monitor drive pattern

- Test monitor drive pattern for ect

Caution:

Perform this drive pattern on a level surface and strictly observe the posted speed limits and traffic laws while driving.

Hint:

Performing this drive pattern is one method to simulate the ect's malfunction detection conditions.

The dtcs may not be detected through ordinary, everyday driving. Also, dtcs may not be detected through this drive pattern.

- Preparation for driving

- Warm up the engine sufficiently (engine coolant temperature is 60°c (140°f) or higher).

- Drive the vehicle when the atmospheric

temperature is -10°c (14°f) or higher.

Malfunction is not detected when the atmospheric temperature is less than -10°c (14°f).

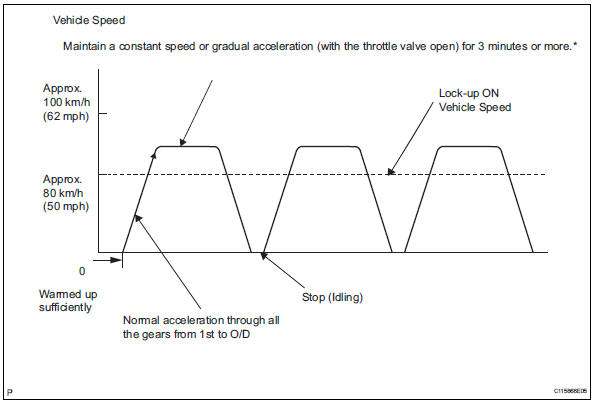

- Drive pattern

- Drive the vehicle through all the gears.

Stop→1st → 2nd →3rd → o/d → o/d (lock-up on).

- Repeat the above drive pattern 3 times or more.

Notice:

- When using the intelligent tester, the monitor status can be found in "enhanced obd ii / data list" or under "carb obd ii".

- In the event that the drive pattern must be interrupted (due to traffic conditions or other factors), the drive pattern can be resumed and, in most cases, the monitor can be completed.

Caution:

Perform this drive pattern on a level road as much as possible and strictly observe the posted speed limits and traffic laws while driving.

Hint:

*: Drive at such a speed in the uppermost gear to engage lock-up. The vehicle can be driven at a speed lower than the speed shown in the above diagram under the lock-up condition.

Notice:

It is necessary to drive the vehicle for approximately 30 minutes to detect dtc p0711 (transmission fluid temperature sensor "a" performance).

Manual shifting test

Manual shifting test

Manual shifting test

Hint:

Through this test, it can be determined whether the

trouble occurs in the electrical circuit or if it is a

mechanical problem in the transaxle.

If any abnorm ...

Problem symptoms table

Problem symptoms table

Hint:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "suspected area"

column ...

Other materials:

Dinghy towing

Your vehicle is not designed

to be dinghy towed (with 4

wheels on the ground)

behind a motor home.

NOTICE

â– To avoid serious damage to

your vehicle

Do not tow your vehicle with 4

wheels on the ground.

â– To prevent causing serious

damage to the transmission

and AWD system (AWD models)

2WD models: ...

Center power outlet socket (for ac power supply)

Components

Removal

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

Remove console rear end panel (see page ip-

19)

...

Evaporative emission control system incorrect purge flow

Dtc summary

Description

The description can be found in the evap (evaporative emission) system (see

page es-335).

Inspection procedure

Refer to the evap system (see page es-340).

Monitor description

The two monitors, key-off and purge flow, are used to detect malfunctions

relating ...