Toyota RAV4 (XA40) 2013-2018 Service Manual: Propeller shaft assembly

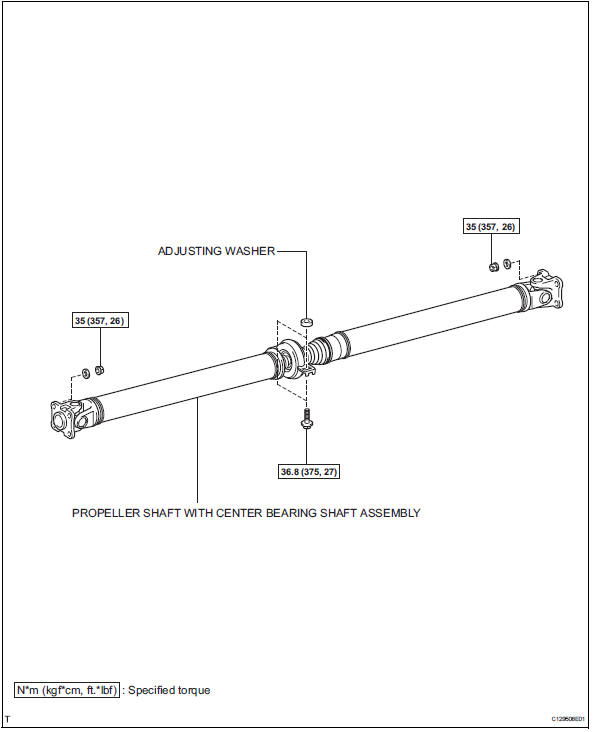

Components

Removal

- Remove propeller shaft with center bearing shaft assembly

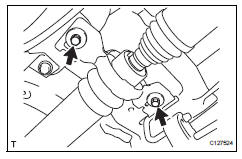

- Remove the 2 bolts and 2 adjusting washers, and disconnect the propeller with center bearing shaft.

Notice:

- During the removal, do not exert excessive force on the universal joint.

- When removing, transporting or storing the propeller with center bearing shaft assembly, do not allow the no. 2 Joint angle to exceed 20Đ®

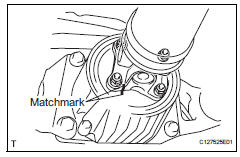

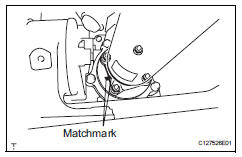

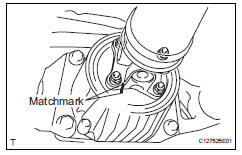

- Place matchmarks on the differential carrier and propeller shaft.

- Remove the 4 nuts and 4 washers, and disconnect the propeller shaft and differential carrier.

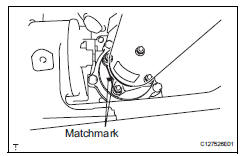

- Place matchmarks on the transfer and propeller shaft.

- Remove the 4 nuts and 4 washers, and disconnect the propeller shaft from the transfer.

Inspection

- Inspect propeller shaft with center bearing shaft assembly

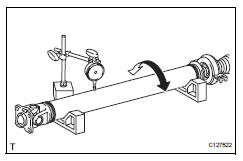

- Using a dial indicator, measure the propeller shaft runout for front side.

Maximum runout: 0.4 Mm (0.02 In.)

If the shaft runout is greater than the maximum, replace the propeller shaft.

Notice:

Place the dial indicator on the center of the shaft, and perpendicular to the shaft.

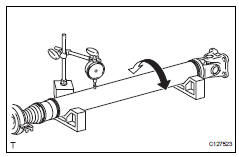

- Using a dial indicator, measure the propeller shaft runout for rear side.

Maximum runout: 0.4 Mm (0.02 In.)

If the shaft runout is greater than the maximum, replace the propeller shaft.

Notice:

Place the dial indicator on the center of the shaft, and perpendicular to the shaft.

- Inspect joint angle

- Before the angle measurement, use procedures like the examples below to stabilize each part.

- Rotate the propeller shaft several times by hand.

- Set the jack to the differential, and raise and lower it.

Notice:

Perform the measurement with a 4 post lift or pit so that the vehicle condition is as close to a standard ground condition as possible.

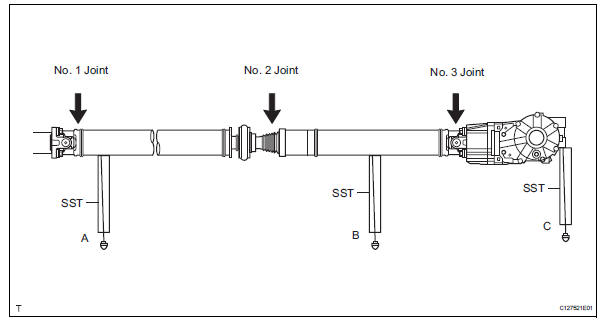

- Using sst, measure the installation angle of the propeller shaft for front side (a in illustration).

Sst 09370-50010 standard angle a:

-2Đ´9'

-3Đ°1' For w/ 3rd seat

- Using sst, measure the installation angle of the propeller shaft for front side (a in illustration) and propeller shaft for rear side (b in illustration).

Sst 09370-50010

Standard angle a-b: 1Đł5'

- Using sst, measure the installation angle of the propeller shaft for rear side (b in illustration) and differential carrier rear side (c in illustration).

Sst 09370-50010

Standard angle b-c: 2Đ°4'

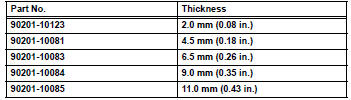

- If the result is not as specified, replace the center support bearing adjusting washer with a more appropriate one.

Notice:

- Use washers of the same thickness on the left and right sides.

- Do not use 2 or more washers stacked together

Standard adjusting washer

Installation

- Temporarily install propeller shaft with center bearing shaft assembly

- Align the matchmarks of the transfer and propeller shaft.

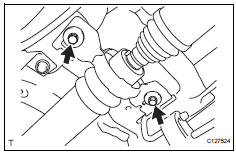

- Temporarily install the propeller shaft with center bearing with the 4 nuts and 4 washers.

- Align the matchmarks of the differential carrier and propeller shaft.

- Temporarily install the propeller shaft with center bearing with the 4 bolts and 4 washers.

- Temporarily install the center support bearing and center support bearing washer with the 2 bolts.

- Tighten propeller shaft with center bearing shaft assembly

- Tighten the 4 nuts of the propeller shaft and transfer

to the torque specification.

Torque: 35 n*m (357 kgf*cm, 26 ft.*Lbf)

- Tighten the 4 nuts of the propeller shaft and

differential carrier to the torque specification.

Torque: 35 n*m (357 kgf*cm, 26 ft.*Lbf)

- Check that the center line of the center support bearing housing is perpendicular to the axis of the propeller shaft.

- Tighten the 2 bolts of the center support bearing to

the torque specification.

Torque: 36.8 N*m (375 kgf*cm, 27 ft.*Lbf)

- Inspect joint angle (see page pr-4)

Propeller shaft system

Propeller shaft system

Problem symptoms table

Hint:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms are

listed in order of probability in the "suspected ...

Seat

Seat

...

Other materials:

Heated steering wheel/seat

heaters/seat ventilators

Heated steering wheel

Warm up the grip of the steering

wheel

Seat heaters

Warm up the seat upholstery

Seat ventilators

Maintain good ventilation by

pulling air through the seat

upholstery

WARNING

â– To prevent minor burn injuries

Care should be taken if anyone in

the following categories ...

On-vehicle inspection

Check accelerator pedal rod

Check the voltage.

Connect the intelligent tester to the dlc3.

Turn the ignition switch on

Turn the intelligent tester on.

Select the menu items: diagnosis /

enhanced obd ii / data list / all /

accel pos #1, accel pos #2.

Operate the acceler ...

Diagnosis system

Description

Sliding roof system data and diagnostic trouble

codes (dtcs) can be read through the vehicle's

data link connector 3 (dlc3). When the system

seems to be malfunctioning, use the intelligent

tester to check for malfunctions and perform repairs.

Check dlc3

The vehi ...