Toyota RAV4 (XA40) 2013-2018 Service Manual: Stuck in deceleration sensor

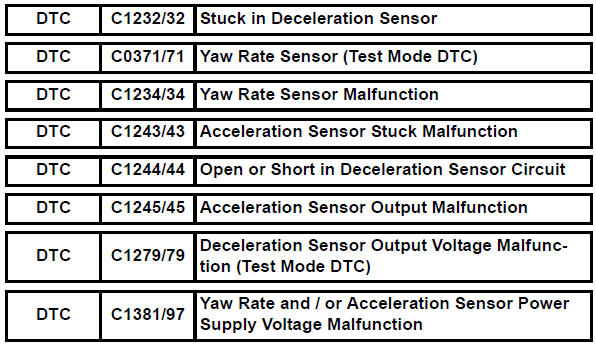

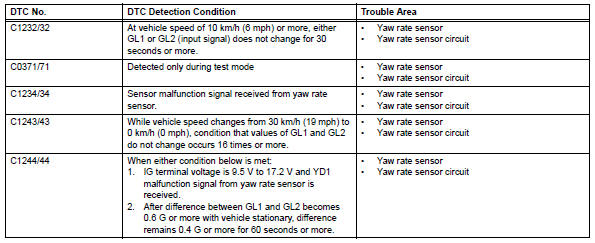

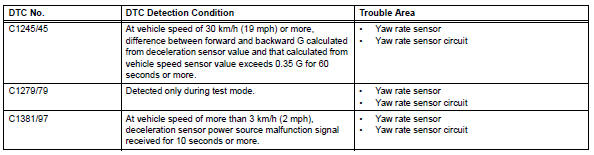

Description

The skid control ecu receives signals from the yaw rate and deceleration sensor via the can communication system.

The yaw rate sensor has a built-in deceleration sensor and detects the vehicle's condition using 2 circuits (gl1: g sensor 1, gl2: g sensor 2).

If there is trouble in the bus lines between the yaw rate and deceleration sensor and the can communication system, dtc u0123/62 (malfunction in can communication with the yaw rate sensor) and u0124/95 (malfunction in can communication with the deceleration sensor) are output.

These dtcs are also output when the calibration has not been completed.

Dtcs c0371/71 and c1279/79 are deleted when the yaw rate and deceleration sensor sends a yaw rate and/or deceleration signal or test mode ends. Dtcs c0371/71 and c1279/79 are output only in test mode.

Wiring diagram

Refer to dtc c1210/23, c1336/39 (see page bc-89).

Inspection procedure

Notice:

When replacing yaw rate and deceleration sensor, perform zero point calibration (see page bc- 24).

Hint:

When dtc u0123/62, u0124/95 or u0126/63 is output together with dtc c1232/32, c1234/34, c1243/ 43, c1244/44, c1245/45, or c1387/97, inspect and repair the trouble areas indicated by dtc u0123/62, u0124/95 or u0126/63 first.

- Check dtc

- Clear the dtc (see page bc-47).

- Turn the ignition switch off.

- Turn the ignition switch on again and check that no can communication system dtc(s) is output.

- Drive the vehicle at a speed of 30 km/h (19 mph) or more and check that no dtcs are output.

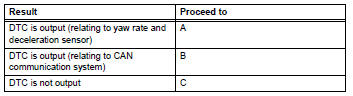

Result

- Check yaw rate sensor installation

- Check that the yaw rate sensor has been installed correctly (see page bc-211).

Ok: the sensor is tightened to the specified torque.

The sensor is not tilted.

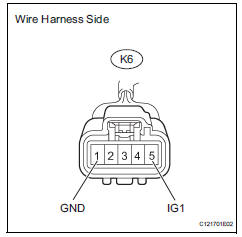

- Check wire harness (yaw rate sensor - battery and body ground)

- Disconnect the k6 sensor connector.

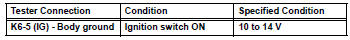

- Measure the voltage of the wire harness side connector.

Standard voltage

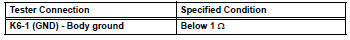

- Measure the resistance of the wire harness side connector.

Standard resistance

Replace yaw rate sensor

Steering angle sensor circuit malfunction

Steering angle sensor circuit malfunction

Description

The steering sensor signal is sent to the skid control ecu via the can

communication system. When

there is a malfunction in the can communication system, it is detected by the

st ...

Low battery positive voltage

Low battery positive voltage

Description

When there is an abnormality in the power supply circuit of the brake

actuator (skid control ecu), the skid

control ecu sets a dtc and the operation is prohibited by the fail-safe ...

Other materials:

Rear occupant classification sensor lh collision detection

Description

Dtc b1787 is output when the occupant classification ecu receives a collision

detection signal sent by

the rear occupant classification sensor lh when an accident occurs.

Dtc b1787 is also output when the front seat assembly rh is subjected to a

strong impact, even if an

actua ...

Evaporator temperature sensor circuit

Description

The no. 1 Cooler thermistor (evaporator temperature sensor) is installed on

the evaporator in the air

conditioning unit to detect the temperature of the cooled air that has passed

through the evaporator and to

control the air conditioner. It sends signals to the air conditioni ...

Air-fuel ratio (a/f) and heated oxygen (ho2) sensor

monitors (active air-fuel ratio control type)

Preconditions

The monitor will not run unless:

2 Minutes or more have elapsed since the engine

was started.

The engine coolant temperature (ect) is 75┬░c

(167┬░f) or more.

Cumulative driving time at a vehicle speed of 48

km/h (30 mph) or more exceeds 6 minutes.

Air-fuel rat ...