Toyota RAV4 (XA40) 2013-2018 Service Manual: Torque converter and drive plate

Inspection

- Inspect torque converter clutch assembly

- Inspect the one-way clutch.

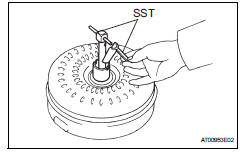

- Install sst to the inner race of the one-way

clutch.

Sst 09350-32014 (09351-32010)

- Set sst so that it fits in the notch of the

converter hub and in the outer race of the oneway

clutch.

Sst 09350-32014 (09351-32020)

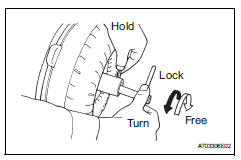

- With the torque converter standing on its side, check that the clutch locks when sst is turned counterclockwise and rotates freely and smoothly when turned clockwise. If the results are not as specified, clean the converter and recheck the one-way clutch. If the results still are not as specified, replace the converter.

- Determine the condition of the torque converter clutch.

- Check that the following conditions are met:

- During the stall test or when the shift lever is on n, metallic sounds are not emitted from the torque converter clutch.

- The one-way clutch turns in one direction and locks in the other direction.

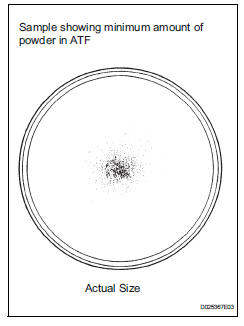

- The amount of powder in the atf is not

greater than the sample shown in the

illustration.

If the results are not as specified, replace the torque converter clutch assembly.

Hint:

The sample illustration shows approximately 0.25 Liters (0.26 Us qts, 0.22 Imp. Qts) of the atf taken from a removed torque converter clutch.

- Replace the atf in the torque converter clutch.

- If the atf is discolored and/or has a foul odor, stir the atf in the torque converter clutch thoroughly and drain the atf with the torque converter facing upward.

- Clean and check the oil cooler and oil pipe line.

- If the torque converter clutch is inspected or the atf is replaced, clean the oil cooler and oil pipe line.

- Apply compressed air of 196 kpa (2 kgf/cm2, 28 psi) into the inlet hose.

- If a large amount of powder is found in the atf, add new atf using a bucket pump and clean the oil cooler and oil pipe line again.

- If the atf is cloudy, inspect the oil cooler (radiator).

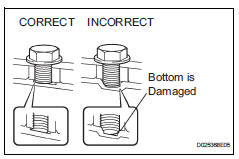

- Prevent deformation of the torque converter clutch and damage to the oil pump gear.

- When any marks due to interference are found on the end of the bolt for the torque converter clutch and on the bottom of the bolt hole, replace the bolt and torque converter clutch.

- All of the bolts should be the same length.

- Make sure no spring washers are missing.

- Inspect drive plate and ring gear subassembly

- Set up a dial indicator and measure the drive plate runout.

Maximum runout: 0.30 Mm (0.0118 In.)

If the runout is greater than the maximum or if the ring gear is damaged, replace the drive plate. If installing a new drive plate, note the orientation of the spacers and tighten the bolts.

Torque: 98 n*m (999 kgf*cm, 72 ft.*Lbf)

- Check the ring gear for any damage.

If the ring gear is damaged, replace the drive plate.

Automatic transaxle assembly

Automatic transaxle assembly

Components

Removal

Remove engine assembly with transaxle

Remove the engine with transaxle (see page em-

98).

Drain automatic transaxle fluid

Remove the drain plug and gask ...

Automatic transaxle unit

Automatic transaxle unit

Components

...

Other materials:

Bluetooth®

When using the bluetooth® audio system

In the following conditions, the system may not function.

If the portable audio player is turned off

If the portable audio player is not connected

If the portable audio player’s battery is low

There may be a delay if a cellular phone connection i ...

Making a phone call

To enter the “phone” mode, press the off-hook switch.

Making a phone call

Dialing by inputting a name

Speed dialing

Dialing by entering the number

Dialing from call histories

Receiving a phone call

Answering the phone

Refusing the call

Operations during a call

Transfer ...

Reassembly

Hint:

Use the same procedures for the rh side and lh side.

The procedures listed below are for the lh side.

Install seat lock release band

Install the band with nut.

Hint:

After installing the band, feed it through the

seatback frame hole towards the rear of the vehicle.

I ...