Toyota RAV4 (XA40) 2013-2018 Service Manual: Yaw rate and deceleration sensor

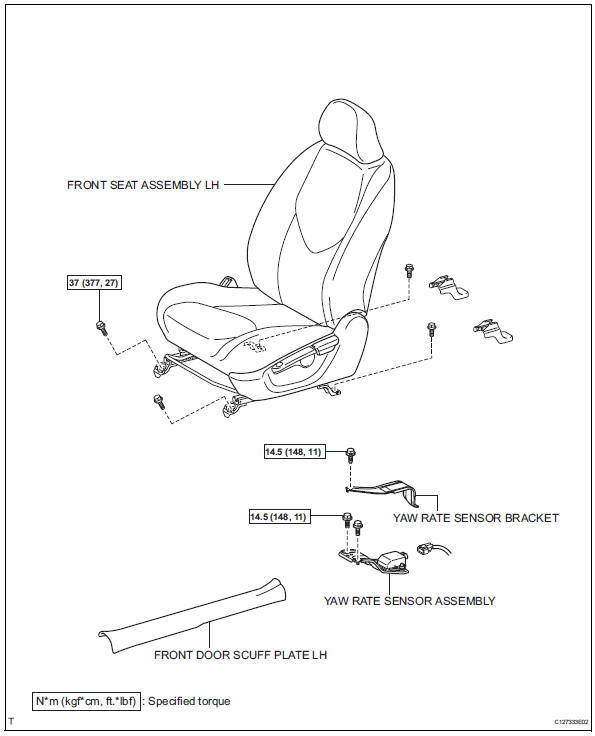

Components

Removal

- Disconnect cable from negative battery terminal

Caution:

Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to prevent airbag and seat belt pretensioner activation.

- Remove front seat assembly lh

- For manual seat: remove the front seat lh (see page se-11).

- For power seat: remove the front seat lh (see page se-27).

- Remove front door scuff plate lh (see page ir-26)

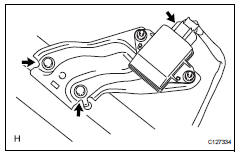

- Remove yaw rate sensor bracket

- Remove the bolt and yaw rate sensor bracket.

- Remove yaw rate sensor assembly

- Disconnect the yaw rate sensor connector.

- Remove the 2 bolts and yaw rate sensor.

Notice:

Do not remove the sensor from the bracket.

Inspection

- Inspect yaw rate sensor

- Inspect the yaw rate sensor. If any of the following occurs, replace the yaw rate sensor with a new one.

- The surface of the sensor is cracked, dented, or chipped.

- The connector or wire harness is scratched, cracked, or damaged.

- The sensor has been dropped.

Installation

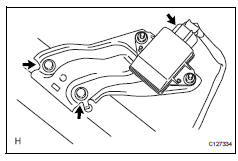

- Install yaw rate sensor assembly

- Install the yaw rate sensor with the 2 bolts.

Torque: 14.5 N*m (148 kgf*cm, 11 ft.*Lbf)

Notice:

- Do not damage the yaw rate sensor.

- Make sure that the yaw rate sensor is installed securely.

- Connect the yaw rate sensor connector.

- Install yaw rate sensor bracket

- Install the bracket with the bolt.

Torque: 14.5 N*m (148 kgf*cm, 11 ft.*Lbf)

- Install front door scuff plate lh (see page ir-59)

- Install front seat assembly lh

- For manual seat: install the front seat (see page se-22).

- For power seat: install the front seat (see page se-37).

- Connect cable to negative battery terminal

- Perform zero point calibration of yaw rate and deceleration sensor

- Perform the yaw rate and deceleration sensor zero point calibration (see page bc-24).

- Inspect yaw rate sensor signal

- Inspect the yaw rate sensor signal (see page bc- 28).

Rear speed sensor (for 4wd)

Rear speed sensor (for 4wd)

Components

Removal

Hint:

Use the same procedures for the lh side and rh side.

The procedures listed below are for the lh side.

Disconnect cable from negative battery

terminal

Ca ...

Steering angle sensor

Steering angle sensor

Components

Removal

Precaution

Caution:

Be sure to read the "precaution" thoroughly

before servicing (see page rs-1).

Disconnect cable from negative battery

terminal

Ca ...

Other materials:

Components

(2006/01- )

...

Garage door opener

The garage door opener can

be programmed using the

HomeLink to operate

garage doors, gates, entry

doors, door locks, home

lighting systems, security

systems, and other devices.

тЦаHomeLink programming procedure

The programming procedures can

also be found at the following URL.

System components

The ...

Power outlets

The power outlet can be used for 12 v accessories that run on

less than 10 a.

Open the lid.

The power outlets can be used when

Vehicles without a smart key system

The engine switch is in the тАЬaccтАЭ or тАЬonтАЭ position.

Vehicles with a smart key system

The engine switch is in ...