Toyota RAV4 (XA40) 2013-2018 Service Manual: Fuel injector

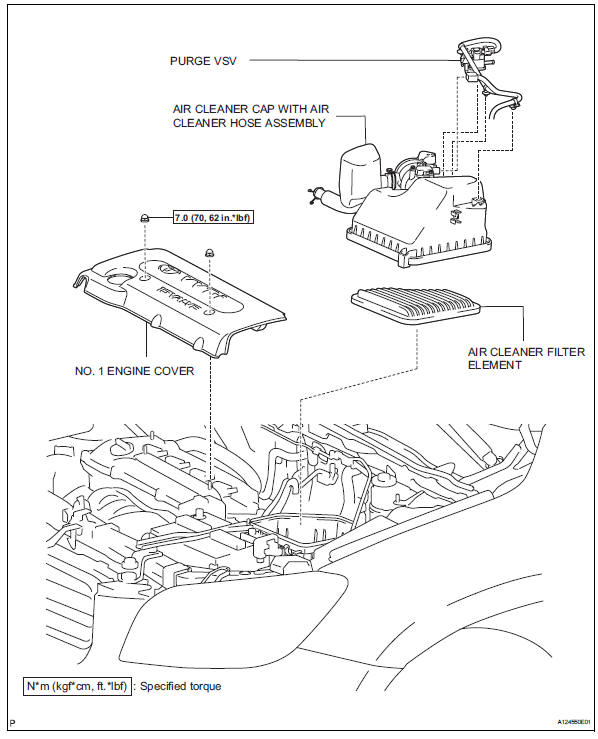

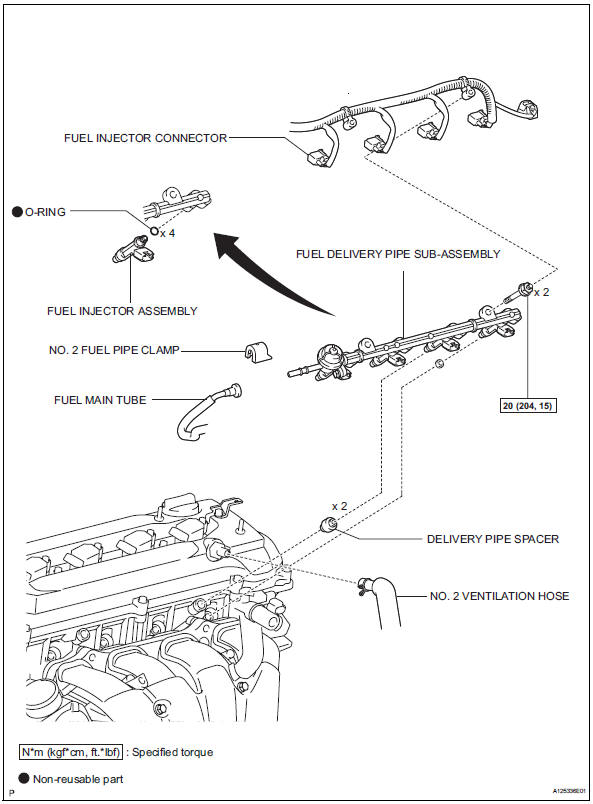

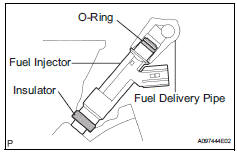

Components

Removal

- Discharge fuel system pressure

Caution:

- Discharge fuel system pressure procedures must be performed before disconnecting any part of the fuel system.

- After performing the discharge fuel system pressure procedures, pressure will remain in the fuel line. When disconnecting the fuel line, place a cloth or equivalent over fittings to reduce the risk of fuel spray.

- Remove the console box (see page ir-83).

- Disconnect the connector.

- Start the engine. After the engine has stopped, turn the ignition switch off.

Hint:

Dtc p0171 (system too lean) may be set.

- Check that the engine does not start.

- Remove the fuel tank cap, and let the air out of the fuel tank.

- Connect the connector.

- Install the console box (see page ir-90).

- Disconnect cable from negative battery terminal

Caution:

Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to prevent airbag and seat belt pretensioner activation.

- Remove no. 1 Engine cover (see page es-410)

- Remove air cleaner cap sub-assembly (see page es-411)

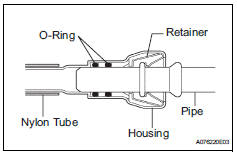

- Disconnect fuel main tube

Notice:

Do not forcibly bend and twist the fuel main tube.

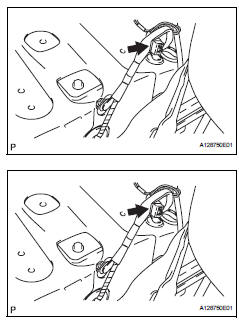

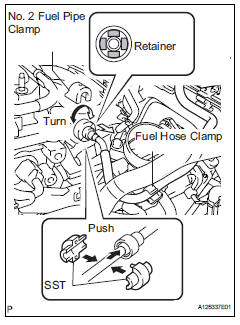

- Remove the fuel tube from the fuel hose clamp.

- Remove the fuel pipe clamp.

- Wipe off any dirt on the fuel tube connector.

- Hold the fuel tube connector, and then install sst.

Sst 09268-21010

- Turn sst to align the retainer inside the fuel tube connector with the chamfered part of sst.

- Insert sst into the fuel tube and hold it. Then push the fuel tube connector toward sst side.

- Mount the retainer of the fuel tube connector onto the chamfered part of sst.

- Slide sst and fuel tube connector together towards the fuel tube until they make a "click" sound, and then disconnect the fuel tube.

- Drain the fuel remaining inside the fuel tube.

- Cover the fuel tube and fuel pipe with a plastic bag to protect the disconnected part.

- Disconnect no. 2 ventilation hose

- Disconnect the no. 2 Ventilation hose from the ventilation valve.

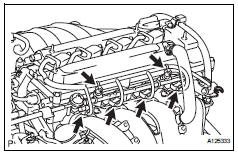

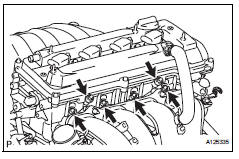

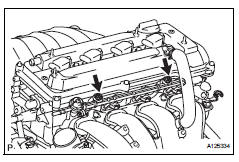

- Remove fuel delivery pipe sub-assembly

- Remove the 2 wire harness clamps.

- Disconnect the 4 fuel injector connectors.

- Remove the 2 bolts, then remove the fuel delivery pipe together with the 4 fuel injectors.

Notice:

Be careful not to drop the fuel injectors when removing the fuel delivery pipe.

- Remove the 2 delivery pipe spacers from the cylinder head.

- Remove the 4 insulators from the cylinder head.

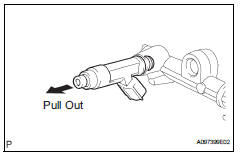

- Remove fuel injector assembly

- Pull the 4 fuel injectors out of the fuel delivery pipe.

Inspection

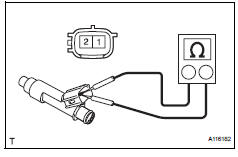

- Inspect fuel injector assembly

- Measure the resistance between the injector terminals.

Standard resistance: 11.6 To 12.4 ٠at 20°c (68°f)

If the result is not as specified, replace the injector.

- Inspect the injector injection.

Caution:

Keep the injector away from sparks during the test.

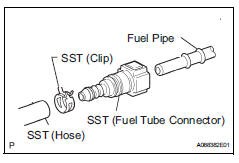

- Connect sst (fuel tube connector) to sst (hose), then connect them to the fuel pipe (vehicle side).

Sst 09268-31011 (09268-41500, 90467- 13001, 95336-08070)

- Install the o-ring to the fuel injector.

- Connect sst (adapter and hose) to the injector, and hold the injector and union with sst (clamp).

Sst 09268-31011 (09268-41110, 09268- 41130, 09268-41310)

- Put the injector into the graduated cylinder.

Caution:

Install a suitable vinyl tube onto the injector to contain gasoline spray.

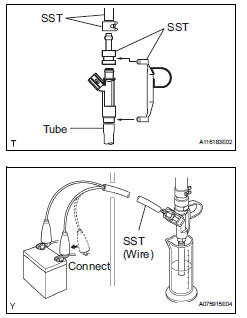

- Operate the fuel pump.

- Connect sst (wire) to the injector and the

battery for 15 seconds, and measure the

injection volume with the graduated cylinder.

Test each injector 2 or 3 times.

Sst 09842-30080

Standard injection volume: 76 to 92 cm3 (4.6 To 5.6 Cu in.) Per 15 seconds

Standard difference between each injector: 16 cm3 (1.0 Cu in.) Or less

- Inspect the fuel leakage.

- Disconnect the sst (wire) tester probes from the battery and check the fuel leakage from the injector.

Standard fuel drop: 1 drop or less per 12 minutes

- Turn the ignition switch off.

- Disconnect the cable from the negative (-) battery terminal.

- Remove sst.

Sst 09842-30080

- Disconnect the intelligent tester from the dlc3.

- Reconnect the fuel inlet hose (rear fuel pipe) to the fuel main tube.

Installation

- Install fuel injector assembly

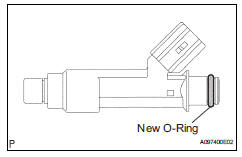

- Apply a light coat of gasoline or spindle oil to new orings, then install one onto each fuel injector.

- Apply a light coat of gasoline or spindle oil to the part of the fuel delivery pipe which comes into contact with the o-ring of the fuel injector.

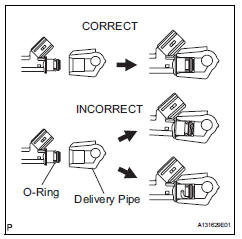

- Apply a light coat of gasoline or spindle oil to the oring again, then install the right and left fuel injectors onto the fuel delivery pipe.

Notice:

Make sure that the o-ring is not cracked or jammed when installing.

- Check that the fuel injector rotates smoothly. If the fuel injector does not rotate, replace the o-ring.

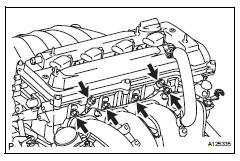

- Install fuel delivery pipe sub-assembly

- Install 4 new insulators into the cylinder head.

- Install the 2 delivery pipe spacers onto the cylinder head.

- Install the fuel delivery pipe together with the 4 fuel injectors, then temporarily tighten the 2 bolts.

Notice:

Be careful not to drop the fuel injectors when installing the fuel delivery pipe.

- Check that the fuel injector rotates smoothly.

If the fuel injector does not rotate, replace the oring.

- Tighten the 2 bolts to the specified torque.

Torque: 20 n*m (205 kgf*cm, 15 ft.*Lb

f)

- Connect the 4 fuel injector connectors.

- Install the 2 wire harness clamps.

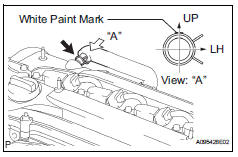

- Connect no. 2 Ventilation hose

- Connect the ventilation hose to the ventilation valve.

Notice:

Make sure that the paint mark and hose clamp are at the correct angle when installing the hose.

- Connect fuel main tube

- Connect the fuel main tube.

- Push the fuel tube connector until it makes a "click" sound.

- Install the fuel pipe clamp.

- Install the fuel tube to the fuel hose clamp.

- Install air cleaner cap sub-assembly (see page es-413)

- Install no. 1 Engine cover (see page es-414)

- Connect cable to battery negative terminal

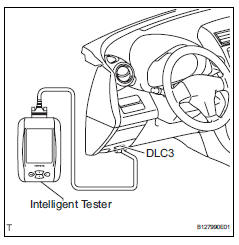

- Check for fuel leakage

- Make sure that there are no fuel leaks after performing maintenance on the fuel system.

- Connect the intelligent tester to the dlc3.

- Turn the ignition switch on, and push the intelligent tester main switch on.

Notice:

Do not start the engine.

- Select the active test mode on the intelligent tester.

Hint:

Refer to the intelligent tester operator's manual for further details.

- Check that there are no leaks from the fuel system.

- Turn the ignition switch off.

- Disconnect the intelligent tester from the dlc3.

Fuel system

Fuel system

Precaution

Before working on fuel system

Do not work near an open flame.

Keep gasoline away from rubber and leather parts.

Discharge the fuel pressure before disconnecting

the fuel lin ...

Fuel pressure regulator

Fuel pressure regulator

Components

Removal

Remove fuel tank assembly

Remove the fuel tank (see page fu-39).

Remove fuel tank main tube sub-assembly

Remove the joint clip and fuel tank main tube ...

Other materials:

Data list / active test (2006/01- )

Read data list

Hint:

Using the intelligent tester's data list allows switch,

sensor, actuator and other item values to be read without

removing any parts. Reading the data list early in

troubleshooting is one way to save time.

Connect the intelligent tester (with can vim) to the

...

How to proceed with troubleshooting

Notice:

Dtcs for the can communication system are as

follows: u0073, u0100, u0105, u0121, u0122, u0123,

u0124, u0126, u0129, c1280, c1296, c1297, and

b1499.

Refer to the troubleshooting procedures of each

system if dtcs regarding the can communication

system are not output.

Turn th ...

Rear seats

Adjustment procedure

Pull up the lever. Then lean back to the desired angle and release the

lever.

When a person sits in the rear center position, align all seatbacks at the

same angle.

Folding down the rear seatbacks

Before folding down the rear seatbacks

Stow the rear center seat bel ...