Toyota RAV4 (XA40) 2013-2018 Service Manual: Air fuel ratio sensor

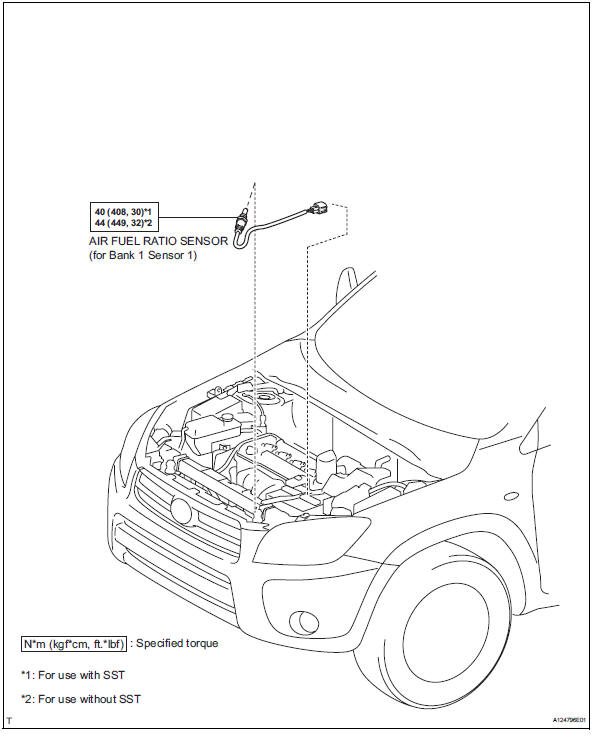

Components

On-vehicle inspection

- Check air fuel ratio compensation system

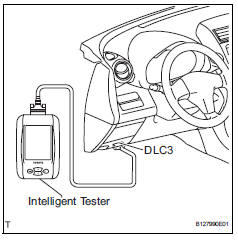

- Connect the intelligent tester to the dlc3.

- Turn the ignition switch on.

- Select the following menu items: data list / a/fs b1 s1 and o2s b1 s2.

- Warm up the a/f sensor with the engine speed at 2,500 rpm for approximately 2 minutes.

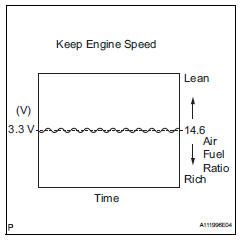

- Keep the engine speed at 2,500 rpm and confirm that the display of "a/fs b1 s1" is as shown in the illustration.

Hint:

- The illustration may slightly differ from the display on the intelligent tester.

- Only the intelligent tester displays the waveform of the a/f sensor.

- Confirm that the display of "o2s b1 s2" changes between 0 to 1 v with the engine speed at 2,500 rpm.

Ok: the voltage output oscillates more than 8 times in 10 seconds.

Notice:

- Perform the check immediately after warming the engine up.

- If the voltage variation could not be verified, warm up the a/f sensor again. If it could not be verified even after warming up the sensor again, check for dtcs (see page es-292).

Removal

- Disconnect cable from negative battery terminal

Caution:

Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to prevent airbag and seat belt pretensioner activation.

- Remove air fuel ratio sensor (for bank 1 sensor 1)

- Disconnect the sensor connector.

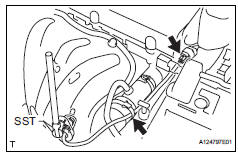

- Using sst, remove the sensor from the exhaust manifold.

Sst 09224-00010

Inspection

- Inspect air fuel ratio sensor (for bank 1 sensor 1)

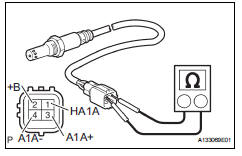

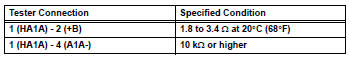

- Measure the resistance of the sensor.

Standard resistance

If the resistance is not as specified, replace the sensor.

Installation

- Install air fuel ratio sensor (for bank 1 sensor 1)

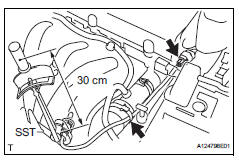

- Using sst, install the sensor to the exhaust manifold.

Sst 09224-00010

Torque: 40 n*m (408 kgf*cm, 30 ft.*Lbf) for use with sst

44 N*m (449 kgf*cm, 32 ft.*Lbf) for use without sst

Hint:

- Use a torque wrench with a fulcrum length of 30 cm (11.81 In.).

- Make sure sst and wrench are connected in a straight line.

- Connect the sensor connector.

- Connect cable to negative battery terminal

- Check for exhaust gas leaks

Ventilation valve

Ventilation valve

Components

Removal

Remove no. 1 Engine cover (see page em-22)

Remove ventilation valve sub-assembly

Disconnect the ventilation hose from the ventilation

valve.

Using a ...

Heated oxygen sensor

Heated oxygen sensor

Components

Removal

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent ai ...

Other materials:

Data list / active test

Read data list

Hint:

Using the intelligent tester's data list allows switch,

actuator and other item values to be read without

removing any parts. Reading the data list early in

troubleshooting is one way to save time.

Connect the intelligent tester (with can vim) to the

dlc3.

Turn ...

System diagram

System diagram (2005/11-2006/01)

System diagram (2006/01- )

...

Tire information

Typical tire symbols

Full-size tire

Compact spare tire

Tire size

DOT and Tire Identification Number (TIN)

Location of treadwear indicators

Tire ply composition and materials

Plies are layers of rubber-coated parallel cords. Cords are the strands

which form the plies in a tire.

Radial tir ...