Toyota RAV4 (XA40) 2013-2018 Service Manual: Brake switch "b" circuit high

![]()

Description

The purpose of this circuit is to prevent the engine from stalling while driving in the lock-up condition when the brakes are suddenly applied.

When the brake pedal is depressed, this switch sends a signal to the ecm. Then the ecm cancels the operation of the lock-up clutch while braking is in progress.

Monitor description

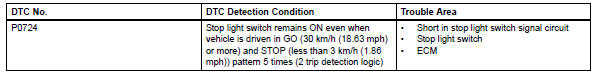

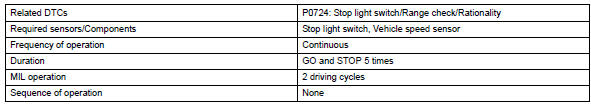

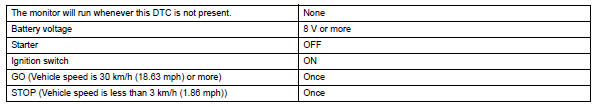

This dtc indicates that the stop light switch remains on. When the stop light switch remains on during go and stop driving, the ecm interprets this as a fault in the stop light switch. Then the mil illuminates and the ecm stores the dtc. The vehicle must go (30 km/h (18.63 Mph) or more) and stop (less than 3 km/h (1.86 Mph)) 5 times for 2 driving cycles in order for the dtc to be output.

Monitor strategy

Typical enabling conditions

Typical malfunction thresholds

![]()

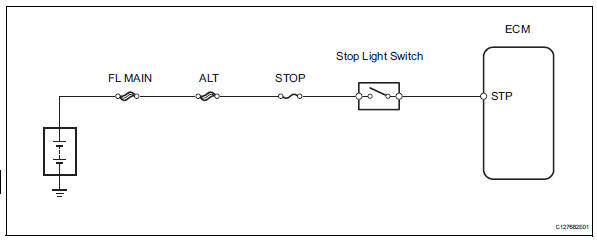

Wiring diagram

Inspection procedure

Hint:

Using the intelligent tester's data list allows switch, sensor, actuator and other item values to be read without removing any parts. Reading the data list early in troubleshooting is one way to save time.

Notice:

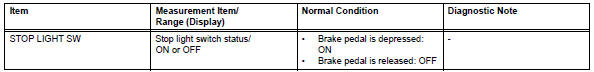

In the table below, the values listed under "normal condition" are reference values. Do not depend solely on these reference values when deciding whether a part is faulty or not.

- Warm up the engine.

- Turn the ignition switch off.

- Connect the intelligent tester to the can vim. Then connect the can vim to the dlc3.

- Turn the ignition switch on

- Turn the intelligent tester on.

- Enter the following menus: diagnosis / enhanced obd ii / data list.

- Follow the instructions on the tester and read the data list.

- Inspect stop light switch

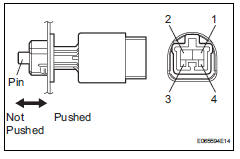

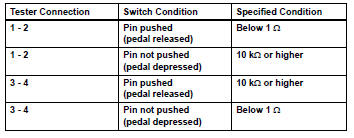

- Remove the a3 stop light switch.

- Measure the resistance of the switch.

Standard resistance

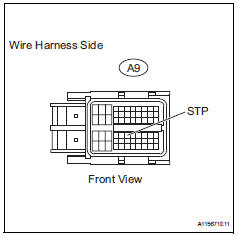

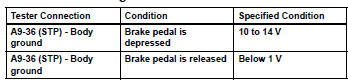

- Check wire harness (ecm - battery)

- Measure the voltage of the wire harness side connector.

Standard voltage

Vin not programmed or mismatch - ecm / pcm

Vin not programmed or mismatch - ecm / pcm

Description

Dtc p0630 is set when the vehicle identification number (vin) is not stored

in the engine control module

(ecm) or the input vin is incorrect. Input the vin with the intelligent tester. ...

Battery current sensor circuit

Battery current sensor circuit

Description

The battery current sensor installed on the positive (+) battery terminal

detects the amount of current

supplied from the generator.

The battery current sensor changes curre ...

Other materials:

Diagnostic trouble code chart (2006/01- )

Hint:

When the air conditioning system functions properly, dtc

b1400/00 is output.

Hint:

*1: Dtc b1422/22 (compressor lock sensor circuit) is

indicated only for a currently occurring malfunction for 2grfe.

To confirm dtc b1422/22, perform the following steps:

With the ignition swit ...

Towing related terms

Gcwr (gross combination weight rating)

The maximum allowable gross

combination weight. The gross

combination weight is the sum

of the total vehicle weight

(including the occupants, cargo

and any optional equipment

installed on the vehicle) and the

weight of the trailer being towed

(inc ...

Installation

Hint:

Use the same procedures for the rh side and lh side.

The procedures listed below are for the lh side.

Install no. 2 Seat leg box protector

Attach the clip to install the protector.

Install the clip.

Install rear no. 1 Floor mat support side plate

Install rear no ...