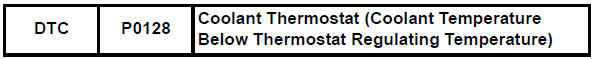

Toyota RAV4 (XA40) 2013-2018 Service Manual: Coolant thermostat (coolant temperature below thermostat regulating temperature)

Hint:

This dtc relates to the thermostat.

Description

This dtc is set when the engine coolant temperature (ect) does not reach 75°c (167°f) despite sufficient engine warm-up time having elapsed.

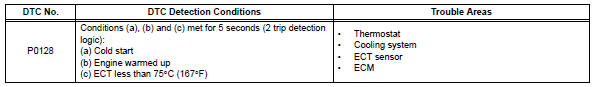

Monitor description

The ecm estimates the ect based on the starting temperature, engine loads, and engine speeds. The ecm then compares the estimated temperature with the actual ect. When the estimated ect reaches 75°c (167°f), the ecm checks the actual ect. If the actual ect is less than 75°c (167°f), the ecm interprets this as a malfunction in the thermostat or the engine cooling system and sets the dtc.

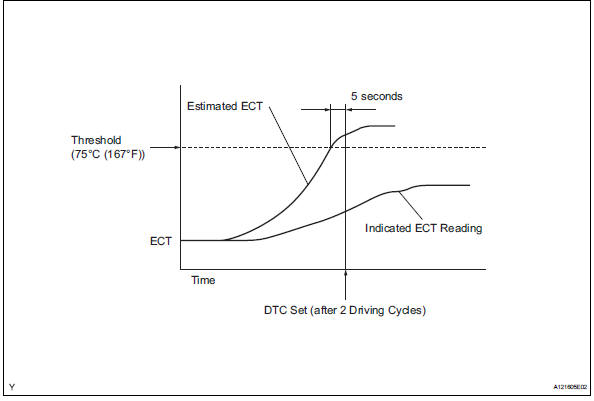

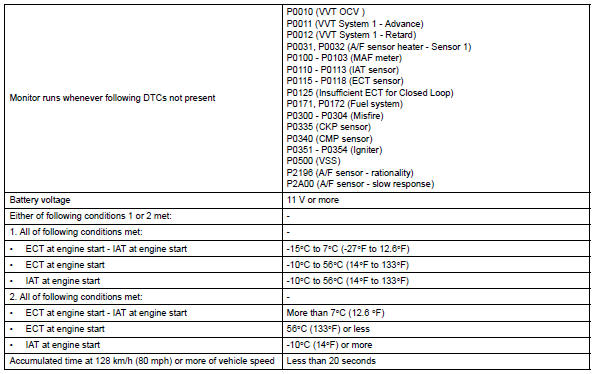

Monitor strategy

![]()

Typical enabling conditions

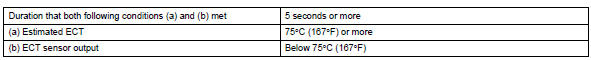

Typical malfunction thresholds

Inspection procedure

Hint:

Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

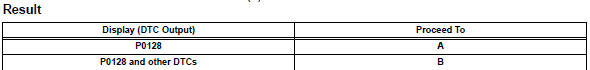

- Check any other dtcs output (in addition to dtc p0128)

- Connect the intelligent tester to the dlc3.

- Turn the ignition switch on.

- Turn the tester on.

- Select the following menu items: diagnosis / enhanced obd ii / dtc info / current codes.

- Read dtcs.

Hint:

If any dtcs other than p0128 are output, troubleshoot those dtcs first.

- Check cooling system

- Check for defects in the cooling system that might cause the system to be too cold, such as abnormal radiator fan operation or any modifications.

- Inspect thermostat

- Remove the thermostat (see page co-15).

- Measure the valve opening temperature of the thermostat.

Standard value: 80 to 84°c (176 to 183°f)

Hint:

In addition to the above check, confirm that the valve is completely closed when the temperature is below the standard.

- Reinstall the thermostat (see page co-15).

Insufficient coolant temperature for closed loop fuel control

Insufficient coolant temperature for closed loop fuel control

Description

Refer to dtc p0115 (see page es-105).

Monitor description

The resistance of the ect sensor varies in proportion to the actual ect. The

ect supplies a constant

voltage to the ...

Oxygen sensor circuit

Oxygen sensor circuit

Description

In order to obtain a high purification rate of the carbon monoxide (co),

hydrocarbon (hc) and nitrogen

oxide (nox) components in the exhaust gas, a twc is used. For the most effici ...

Other materials:

Evaporator temperature sensor circuit

Description

The no. 1 Cooler thermistor (evaporator temperature sensor) is installed on

the evaporator in the air

conditioning unit to detect the temperature of the cooled air that has passed

through the evaporator and to

control the air conditioner. It sends signals to the air conditioni ...

Transmission range sensor circuit malfunction (prndl input)

Description

The park/neutral position (pnp) switch detects the shift lever position and

sends signals to the ecm.

Monitor description

These dtcs indicate a problem with the park/neutral position switch and the

wire harness in the park/

neutral position switch circuit.

The park/neu ...

Diagnostic trouble code chart

If a dtc is displayed during the dtc check, check the circuit

listed for the dtc in the table below (refer to the appropriate

page).

Hint:

When the srs warning light remains on and the normal

system code is output, a decrease in the source voltage is

likely to occur. This malfunction is n ...