Toyota RAV4 (XA40) 2013-2018 Service Manual: Ecm communication stop mode (2005/11-2006/01)

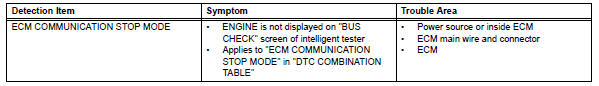

Description

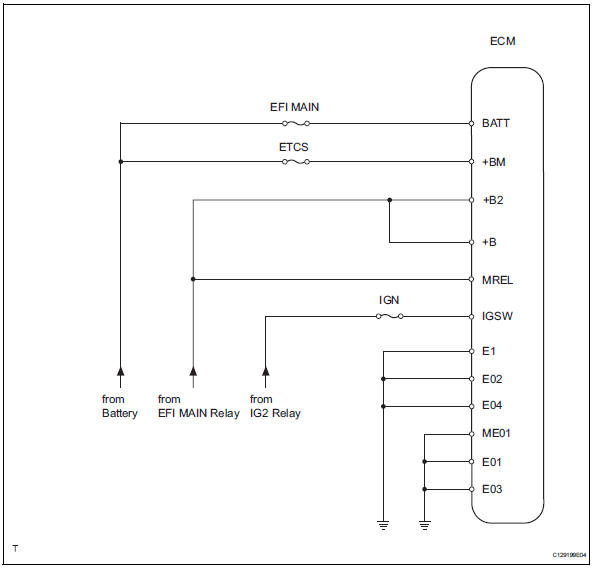

Wiring diagram

Inspection procedure

Notice:

- Turn the ignition switch off before measuring the resistances of the main wire and the branch wire.

- After the ignition switch is turned off, check that the key reminder warning system and light reminder warning system are not in operation.

- Before measuring the resistance, leave the vehicle for at least 1 minute and do not operate the ignition switch, any switches or doors. If doors need to be opened in order to check connectors, open the doors and leave them open.

Hint:

Operating the ignition switch, any switches or any doors triggers related ecu and sensor communication with the can, which causes resistance variation.

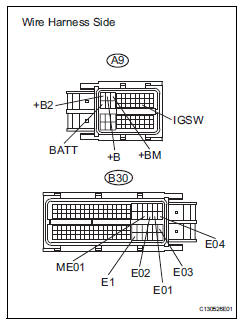

- Check wire harness (ecm - battery and body ground)

- Disconnect the a9 and b30 ecm connectors.

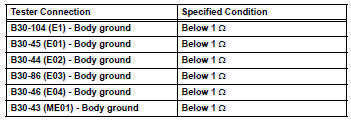

- Measure the resistance of the wire harness side connector.

Standard resistance

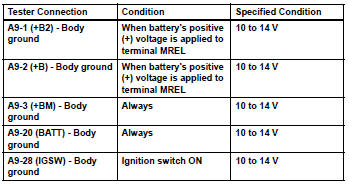

- Measure the voltage of the wire harness side connector.

Standard voltage

Replace ecm

Yaw rate sensor communication stop mode

Yaw rate sensor communication stop mode

Description

Wiring diagram

Inspection procedure

Notice:

Turn the ignition switch off before measuring the resistances of the

main wire and the branch

wire.

After the ignition swi ...

Ecm communication stop mode (2006/01- )

Ecm communication stop mode (2006/01- )

Description

Wiring diagram

Inspection procedure

Notice:

Turn the ignition switch off before measuring the resistances of the

main wire and branch

wire.

After the ignition swi ...

Other materials:

Hill-start assist control

When the engine is stopped by

the Stop & Start system when

the vehicle is on an incline,

when the brake pedal is

released, brake force is temporarily

maintained to prevent the

vehicle from rolling backwards

before the engine is restarted

and drive force is generated.

When drive force is generat ...

Screen for general settings

Press the “setup” button.

Select “general” on the “setup”

screen.

“English”, “français” or

“español” can be selected.

On/off can be selected to

sound beeps.

Select to change the screen

color.

Select to change the keyboard

layout.

...

Front airbag sensor rh circuit malfunction

Description

The front airbag sensor rh consists of the diagnostic circuit, the frontal

deceleration sensor, etc.

If the center airbag sensor assembly receives signals from the frontal

deceleration sensor, it determines

whether or not the srs should be activated.

Dtc b1610/13 is recor ...