Toyota RAV4 (XA40) 2013-2018 Service Manual: Evaporative emission system switching valve control

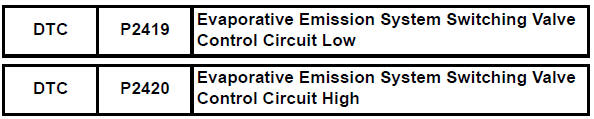

Dtc summary

Hint:

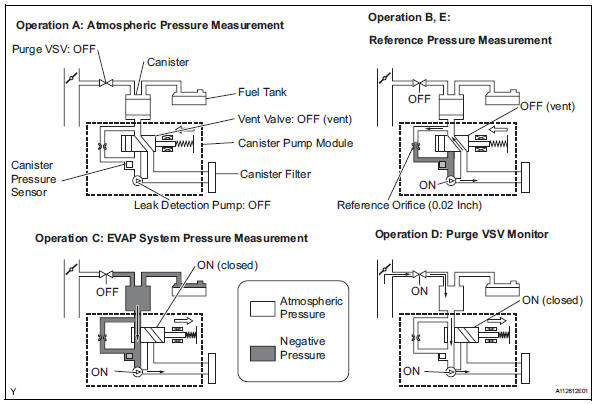

The vent valve is built into the canister pump module.

Description

The description can be found in the evap (evaporative emission) system (see page es-335).

Inspection procedure

Refer to the evap system (see page es-340).

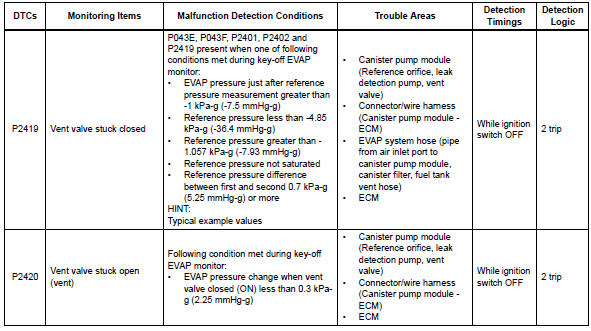

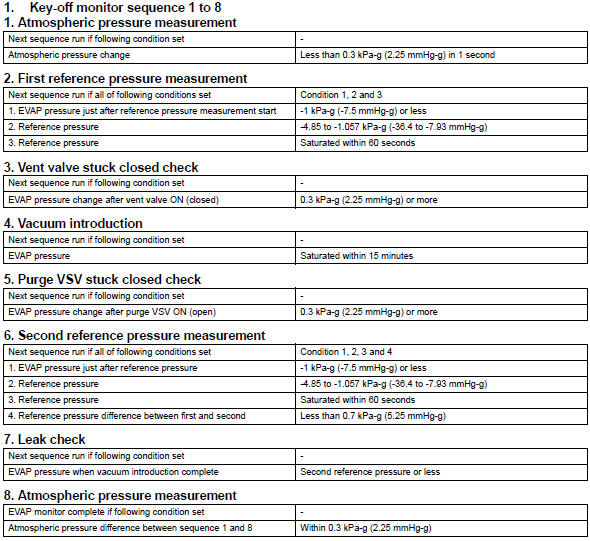

Monitor description

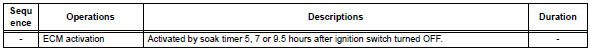

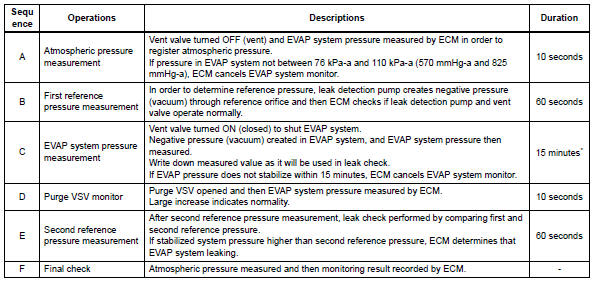

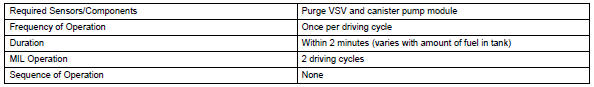

5 Hours* after the ignition switch is turned off, the leak detection pump creates negative pressure (vacuum) in the evap system. The ecm monitors for leaks and actuator malfunctions based on the evap pressure.

Hint:

*: If the engine coolant temperature is not below 35°c (95°f) 5 hours after the ignition switch is turned off, the monitor check starts 2 hours later. If it is still not below 35°c (95°f) 7 hours after the ignition switch is turned off, the monitor check starts 2.5 Hours later.

*: If only a small amount of fuel is in the fuel tank, it takes longer for the evap pressure to stabilize.

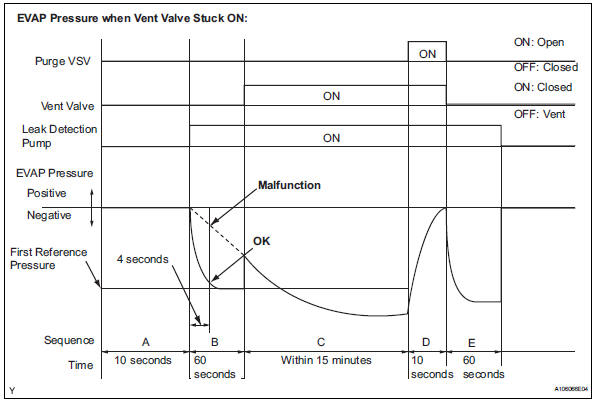

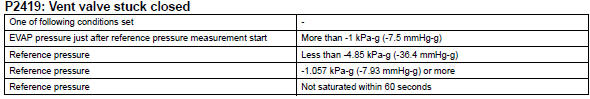

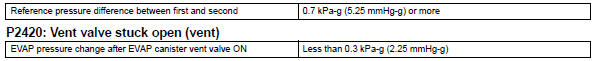

- P2419: vent valve stuck closed

In operation b, the leak detection pump creates negative pressure (a vacuum) through the reference orifice. The evap system pressure is then measured by the ecm, using the canister pressure sensor, to determine the reference pressure. If the pressure exceeds -1.057 Kpa-g (-7.93 Mmhg-g) 4 seconds after the leak detection pump is turned on, the ecm interprets this as the vent valve being stuck closed.

The ecm illuminates the mil and sets the dtc (2 trip detection logic).

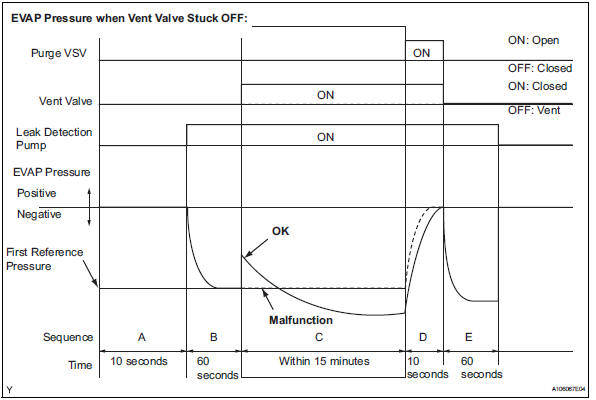

- P2420: vent valve stuck open (vent)

In operation c, the vent valve turns on (closes) and the evap system pressure is then measured by the ecm, using the canister pressure sensor, to conduct an evap leak check. If the pressure does not increase when the vent valve is open, the ecm interprets this as the vent valve being stuck open. The ecm illuminates the mil and sets the dtc.

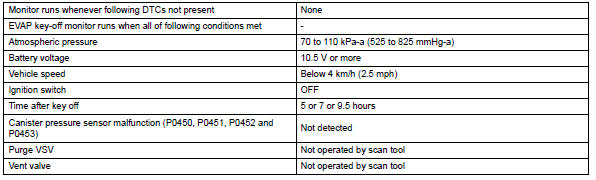

Monitor strategy

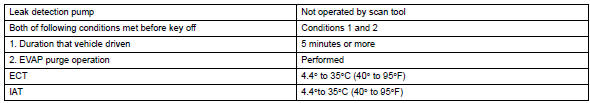

Typical enabling conditions

Typical malfunction thresholds

"Saturated" indicates that the evap pressure change is less than 0.286 Kpa-g (2.14 Mmhg-g) in 60 seconds.

Monitor result

Refer to checking monitor status (see page es-17).

Evaporative emission leak detection pump

Evaporative emission leak detection pump

Dtc summary

Hint:

The leak detection pump is built into the canister pump module.

Description

The description can be found in the evap (evaporative emission) system (see

page es-335).

I ...

Ecm / pcm internal engine off timer performance

Ecm / pcm internal engine off timer performance

Dtc summary

Description

To ensure the accuracy of the evap (evaporative emission) monitor values, the

soak timer, which is built

into the ecm, measures 5 hours (+-15 minutes) from when th ...

Other materials:

Automatic transmission

Select the shift position

depending on your purpose

and situation.

Shift position purpose

and functions

P - Parking the vehicle/

starting the engine

R - Reversing

N - Neutral

D - Normal driving*1

S - S mode driving*2

*1:Shifting to the D position allows

the system to select a gear suitable

for ...

Front power seat lumbar switch

Inspection

Inspect front power seat lumbar switch lh

Measure the resistance between the terminals when

the switch is operated.

Standard resistance

If the result is not as specified, replace the switch. ...

For safe driving

For safe driving, adjust the

seat and mirror to an appropriate

position before driving.

Correct driving posture

Adjust the angle of the seatback

so that you are sitting

straight up and so that you do

not have to lean forward to

steer.

Adjust the seat so that you

can depress the pedals full ...