Toyota RAV4 (XA40) 2013-2018 Service Manual: Freeze frame data

- Description

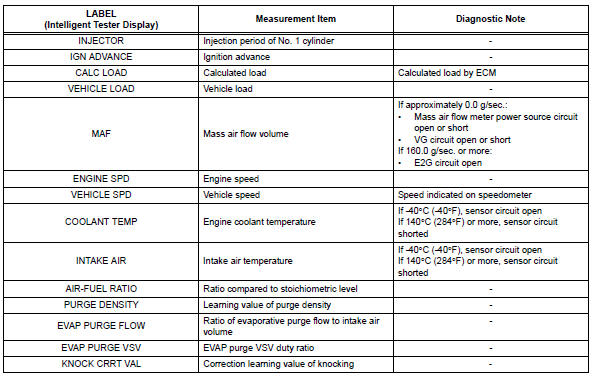

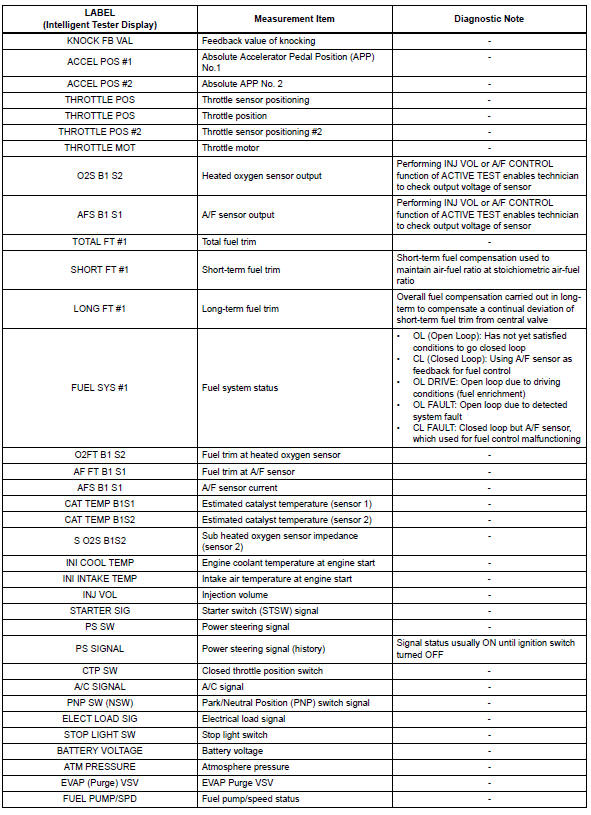

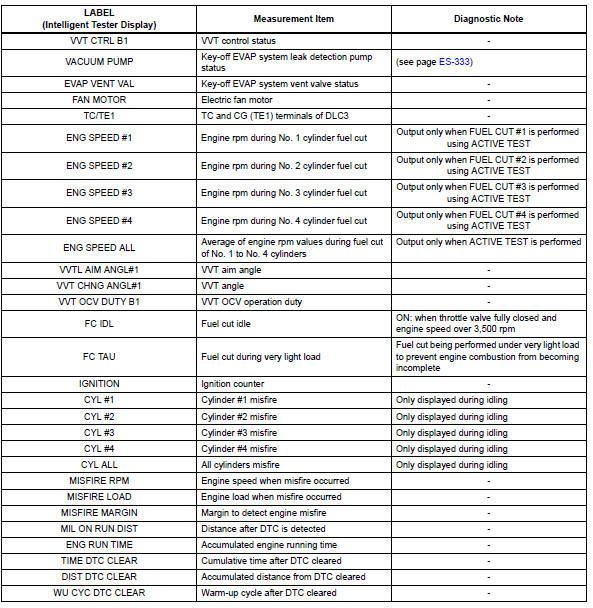

Freeze frame data records the engine conditions (fuel system, calculated load, engine coolant temperature, fuel trim, engine speed, vehicle speed, etc.) When a malfunction is detected. When troubleshooting, it can help determine if the vehicle was running or stopped, the engine was warmed up or not, the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

Hint:

If it is impossible to duplicate the problem even though a dtc is detected, confirm the freeze frame data.

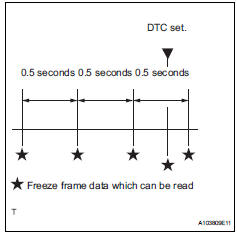

The ecm records engine conditions in the form of freeze frame data every 0.5 Seconds. Using the intelligent tester, 5 separate sets of freeze frame data can be checked.

- 3 Data sets before the dtc was set.

- 1 Data set when the dtc was set.

- 1 Data set after the dtc was set.

These data sets can be used to simulate the condition of the vehicle around the time of the occurrence of the malfunction. The data may assist in identifying the cause of the malfunction, and in judging whether it was temporary or not.

- List of freeze frame data

Dtc check / clear

Dtc check / clear

Notice:

When the diagnosis system is changed from normal

mode to check mode or vice versa, all dtcs and freeze

frame data recorded in normal mode are erased. Before

changing modes, always check an ...

Check mode procedure

Check mode procedure

Hint:

Intelligent tester only:

compared to normal mode, check mode is more sensitive to

malfunctions. Therefore, check mode can detect the

malfunctions that cannot be detected by normal mode.

Not ...

Other materials:

Air conditioning filter

The air conditioning filter must be changed regularly to maintain

air conditioning efficiency.

Removal method

Vehicles without a smart key system: turn the engine switch to the

“lock” position.

Vehicles with a smart key system: turn the engine switch off.

Open the glove box. Slide ...

Solenoid circuit

Description

This solenoid is turned on in accordance with signals from the skid control

ecu and controls the pressure

on the wheel cylinders to control the braking force.

The solenoid and solenoid relay are built into the abs and traction actuator.

Hint:

Dtcs c0226/21, c0236/22, c02 ...

Valve body

Components

Disassembly

Remove shift solenoid valve slt

Remove the bolt, plate and shift solenoid valve slt

from the valve body.

Remove shift solenoid valve sl1

Remove the bolt, plate and shift solenoid valve sl1

from the valve body.

Remove shift solenoid ...