Toyota RAV4 (XA40) 2013-2018 Service Manual: Internal control module random access memory (ram) error

Description

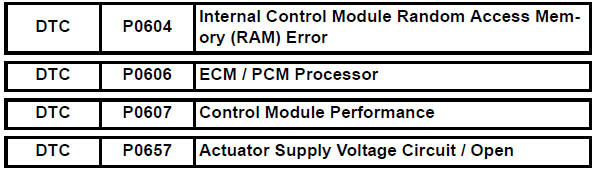

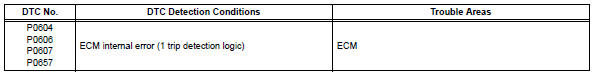

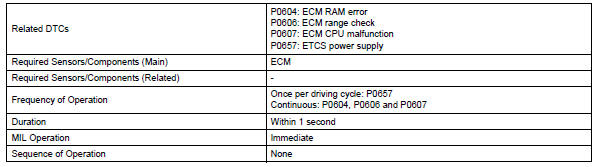

The ecm continuously monitors its own internal memory status, internal circuits, and output signals transmitted to the throttle actuator. This self-check ensures that the ecm is functioning properly. If any malfunction is detected, the ecm sets the appropriate dtc and illuminates the mil.

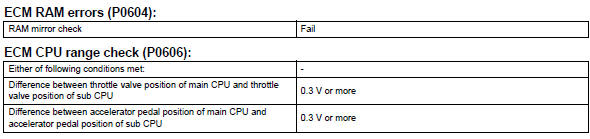

The ecm memory status is diagnosed by internal mirroring of the main cpu and the sub cpu to detect random access memory (ram) errors. The two cpus also perform continuous mutual monitoring. The ecm illuminates the mil and sets a dtc if: 1) outputs from the two cpus are different or deviate from the standards, 2) the signals sent to the throttle actuator deviate from the standards, 3) a malfunction is found in the throttle actuator supply voltage, and 4) any other ecm malfunction is found.

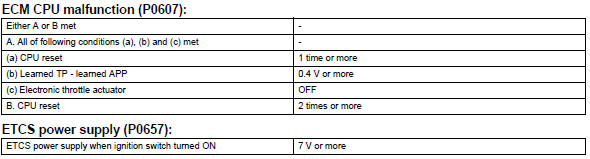

Monitor strategy

Typical enabling conditions

![]()

Typical malfunction thresholds

Inspection procedure

Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

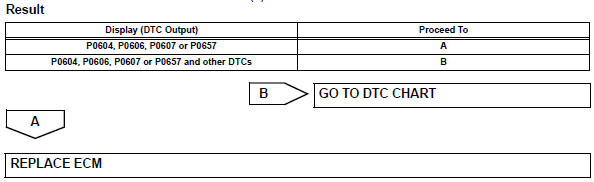

- Check any other dtcs output (in addition to dtc p0604, p0606, p0607 or p0657)

- Connect the intelligent tester to the dlc3.

- Turn the ignition switch on.

- Turn the tester on.

- Select the following menu items: diagnosis / enhanced obd ii / dtc info / current codes.

- Read dtcs.

System voltage

System voltage

Description

The battery supplies electricity to the ecm even when the ignition switch is

in the off position. This

power allows the ecm to store data such as dtc history, freeze frame data and ...

Starter relay circuit high

Starter relay circuit high

Description

While the engine is being cranked, the positive battery voltage is applied to

terminal sta of the ecm. If

the ecm detects the starter control (sta) signal while the vehicle is bein ...

Other materials:

Gauges and meters

The units used on the speedometer may differ depending on the target

region.

Tachometer

Displays the engine speed in revolutions per minute

Speedometer

Displays the vehicle speed

Fuel gauge

Displays the quantity of fuel remaining in the tank

Shift position and shift ran ...

Alarm

The alarm uses light and

sound to give an alert when

an intrusion is detected.

The alarm is triggered in the

following situations when

the alarm is set:

Vehicles without smart key

system: A locked door is

unlocked or opened in any

way other than using the

wireless remote control or

key. (The ...

List screen operation

When a list screen is displayed, use the appropriate buttons to

scroll through the list.

How to scroll

Select to scroll to the next

or previous page.

Appears to the right of

titles, the complete titles are

too long for the display. Select

this button to scroll the title.

Turn th ...