Toyota RAV4 (XA40) 2013-2018 Service Manual: Removal

Hint:

- Use the same procedures for the rh side and lh side.

- The procedures listed below are for the lh side.

- When removing the moulding, heat the vehicle body and moulding using a heat light.

Standard heating temperature

Notice:

Do not heat the vehicle body and moulding excessively.

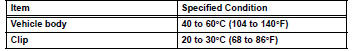

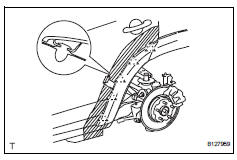

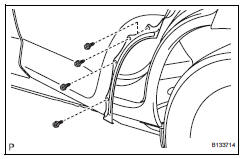

- Remove front fender moulding subassembly lh

- Put protective tape around the moulding.

- Remove the 4 screws and detach the 2 clips.

- Using a moulding remover, detach the 9 clips and remove the moulding.

Notice:

- If reusing the moulding, take care not to damage the moulding.

- Be careful not to damage the vehicle body.

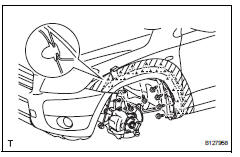

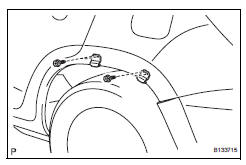

- Remove no. 2 Rear wheel opening extension lh

- Put protective tape around the moulding.

- Remove the screw.

- Using a clip remover, detach the 2 clips and remove the extension.

Notice:

- If reusing the extension, take care not to damage the extension.

- Be careful not to damage the vehicle body.

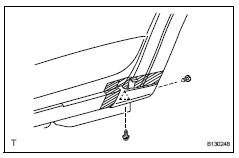

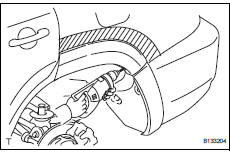

- Remove no. 1 Rear wheel opening extension lh

- Put protective tape around the extension.

- Using a drill bit of less than ö 4 mm (0.16 In.), Drill out the 3 rivet flanges.

Hint:

Wind tape around the drill bit approximately 5 mm (0.20 In.) From the tip of the drill.

Notice:

- Do not drill the rivet at an angle as this will cause damage to the drill and drill hole. Line up the drill and rivet, and carefully drill out the rivet head.

- Be careful as the cut rivet will be very hot.

- Continue drilling and push out the remaining rivet fragments using the drill.

- Using a vacuum cleaner, remove the rivet fragments and shavings from the drilled areas.

- Using a heat light, heat the extension and vehicle body.

- Cut the double-sided tape that holds the moulding to the vehicle body with a knife.

Notice:

- If reusing the extension, take care not to damage the extension.

- Be careful not to damage the vehicle body.

- Using a moulding remover, detach the 5 clips and remove the extension.

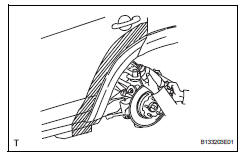

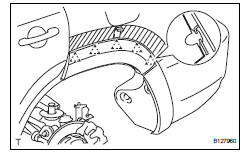

- Remove rear quarter outside moulding lh

- Put protective tape around the moulding.

- Using a drill bit of less than ö 4 mm (0.16 In.), Drill out the 3 rivet flanges.

Hint:

Wind tape around the drill bit approximately 5 mm (0.20 In.) From the tip of the drill.

Notice:

- Do not drill the rivet at an angle as this will cause damage to the drill and drill hole. Line up the drill and rivet, and carefully drill out the rivet head.

- Be careful as the cut rivet will be very hot.

- Continue drilling and push out the remaining rivet fragments using the drill.

- Using a vacuum cleaner, remove the rivet fragments and shavings from the drilled areas.

- Using a heat light, heat the moulding and vehicle body.

- Using a moulding remover, detach the 5 clips and remove the moulding.

Notice:

- If reusing the moulding, take care not to damage the moulding.

- Be careful not to damage the vehicle body.

- Remove no. 2 Rocker panel moulding retainer lh

- Remove the 2 screws and retainer.

- Remove quarter opening retainer lh

- Remove the 4 screws and retainer.

- Remove no. 1 Rocker panel moulding retainer lh

- Remove the 4 screws and 2 retainers.

Outside moulding

Outside moulding

Components

...

Installation

Installation

Hint:

Use the same procedures for the rh side and lh side.

The procedures listed below are for the lh side.

When installing the moulding, heat the vehicle body and

moulding using a heat ligh ...

Other materials:

Maintenance data (fuel, oil

level, etc.)

Dimensions and weights

*1:Unladen vehicle

*2:Vehicles without 235/55R19 tires

*3:Vehicles with 235/55R19 tires

*4:Vehicles without towing package

*5:Vehicles with towing package

Seating capacity

Vehicle identification

â– Vehicle identification number

The vehicle identification number

(VIN) is the ...

Headlight relay circuit

Description

When the light control switch, located on the headlight dimmer switch, is

turned to the head position, the

head relay illuminates the headlights.

Wiring diagram

Inspection procedure

Perform active test by intelligent tester (headlight)

Connect the intelligent tester ( ...

If a warning message is displayed

The multi-information display

shows warnings of system

malfunctions,

incorrectly performed operations,

and messages that

indicate a need for maintenance.

When a message is

shown, perform the correction

procedure appropriate

to the message.

If a warning message is displayed

again after the appropri ...