Toyota RAV4 (XA40) 2013-2018 Service Manual: Shift solenoid "d" performance (shift solenoid valve s4)

System description

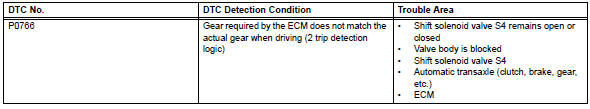

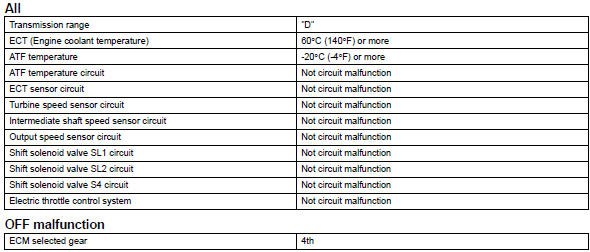

The ecm uses signals from the output shaft speed sensor and input speed sensor to detect the actual gear position (1st, 2nd, 3rd or o/d gear).

Then the ecm compares the actual gear with the shift schedule in the ecm memory to detect mechanical problems of the shift solenoid valves, valve body or automatic transaxle (clutch, brake, gear, etc.).

Monitor description

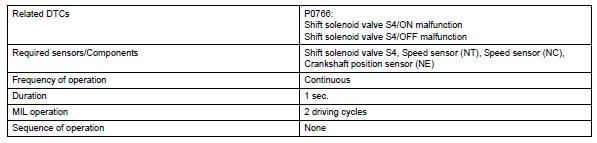

This dtc indicates a stuck off malfunction of the shift solenoid valve s4, stuck on malfunction of the shift solenoid valve sl2, or brake control valve malfunction. The ecm commands gear shifts by turning the shift solenoid valves on/off. When the gear position commanded by the ecm and the actual gear position are not the same, the ecm illuminates the mil and stores the dtc.

Monitor strategy

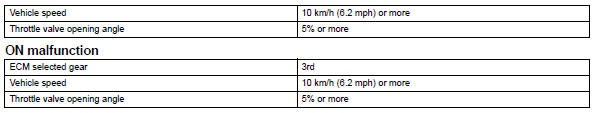

Typical enabling conditions

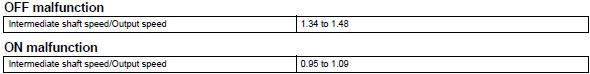

Typical malfunction thresholds

Either of the following conditions is met: off malfunction or on malfunction

2 Detections are necessary per driving cycle: 1st detection: temporary flag on

2Nd detection: pending fault code on

Inspection procedure

Hint:

Performing the intelligent tester's active test allows relay, vsv, actuator and other items to be operated without removing any parts. Performing the active test early in troubleshooting is one way to save time.

The data list can be displayed during the active test.

- Warm up the engine.

- Turn the ignition switch off.

- Connect the intelligent tester to the can vim. Then connect the can vim to the dlc3.

- Turn the ignition switch on and turn the tester on.

- Enter the following menus: diagnosis / enhanced obd ii / active test.

- Follow the instructions on the tester and perform the active test.

Hint:

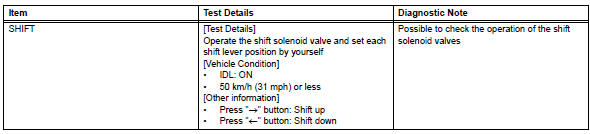

While driving, the shift position can be forcibly changed with the tester.

Comparing the shift position commanded by the active test with the actual shift position enables you to confirm the problem (see page ax-31).

Hint:

- This test can be conducted when the vehicle speed is 50 km/h (31 mph) or less.

- The shift position commanded by the ecm is shown in the data list/shift display on the tester.

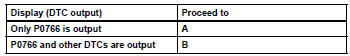

- Check other dtc output (in addition to dtc p0766)

- Connect the intelligent tester to the can vim. Then connect the can vim to the dlc3.

- Turn the ignition switch on and turn the tester on.

- Enter the following menus: diagnosis / enhanced obd ii / dtc info / current codes.

- Read the dtcs using the tester.

Result

Hint:

If any other codes besides p0766 are output, perform troubleshooting for those dtcs first.

- Inspect shift solenoid valve s4

- Remove the shift solenoid valve s4.

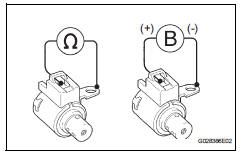

- Measure the resistance between the solenoid valve terminal and solenoid valve body.

Standard resistance:

11 to 15  at 20°c (68°f)

at 20°c (68°f)

- Connect the battery's positive (+) lead to the terminal of the solenoid valve connector, and the negative (-) lead to the solenoid body. Then check that the valve moves and makes an operating noise.

Ok: valve moves and makes operating noise.

- Inspect transmission valve body assembly

- Check the transmission valve body assembly.

Ok: there are no foreign objects on each valve.

- Inspect torque converter clutch assembly

- Check the torque converter clutch assembly (see page ax-153).

Ok: the torque converter clutch operates normally.

Repair or replace automatic transaxle assembly

Pressure control solenoid "A" electrical (shift solenoid valve sl1)

Pressure control solenoid "A" electrical (shift solenoid valve sl1)

Description

Shifting from 1st to o/d is performed in combination with the on and off

operation of the shift solenoid

valves sl1 and sl2, which are controlled by the ecm. If an open or short circu ...

Pressure control solenoid "B" performance (shift solenoid valve sl2)

Pressure control solenoid "B" performance (shift solenoid valve sl2)

Description

The ecm uses signals from the output shaft speed sensor and input speed

sensor to detect the actual

gear position (1st, 2nd, 3rd or o/d gear).

Then the ecm compares the actual g ...

Other materials:

Seat belt pretensioners (front seats)

The pretensioners help the seat

belts to quickly restrain the occupants

by retracting the seat belts

when the vehicle is subjected to

certain types of severe frontal or

side collision or a vehicle rollover.

The pretensioners do not activate

in the event of a minor frontal

impact, a minor ...

Reassembly

Caution:

Wear protective gloves. Sharp areas on the seat frame

(with adjuster) may injure your hands.

Install front seat wire

Install seat position airbag sensor (see

page rs-390)

Install lumbar support adjuster assembly

Install the lumbar support adjuster with the 2

screws.

...

Ignition key cylinder light

Components

Removal

Disconnect cable from negative battery

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

Place front wheels facing straight ahead

Remove steering pad ...