Toyota RAV4 (XA40) 2013-2018 Service Manual: Terminals of ecm

Hint:

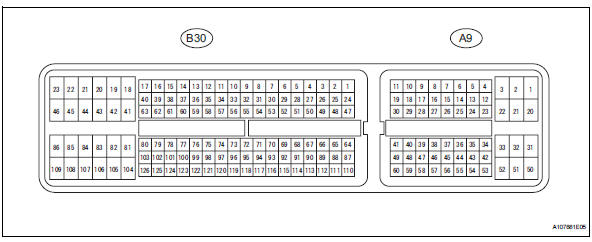

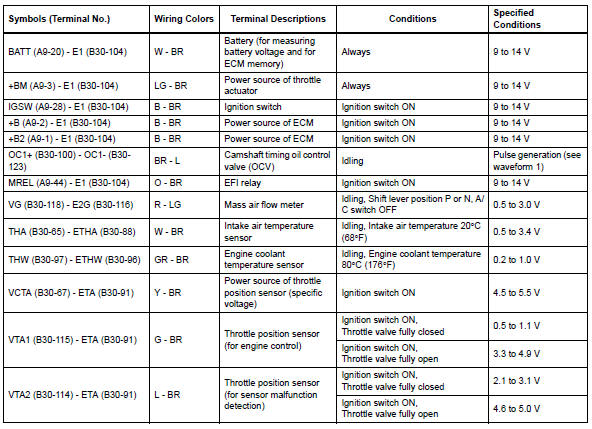

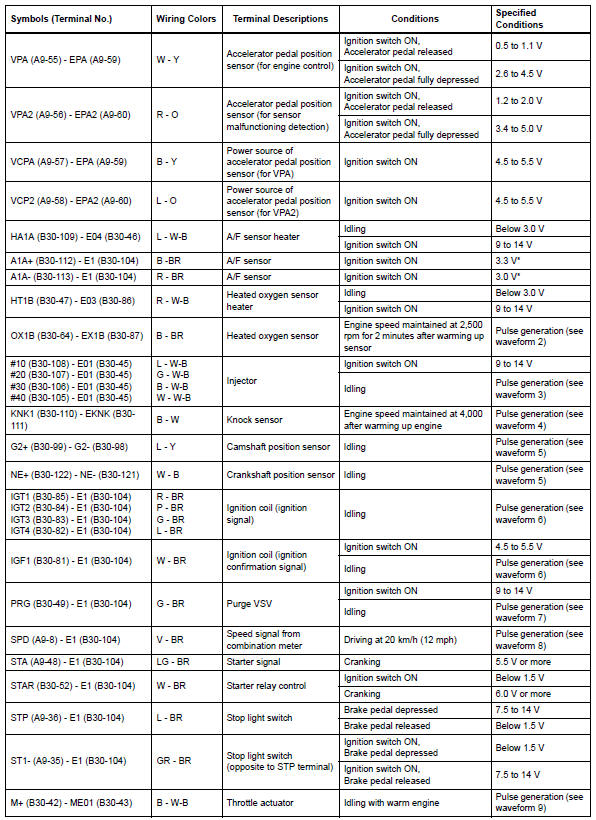

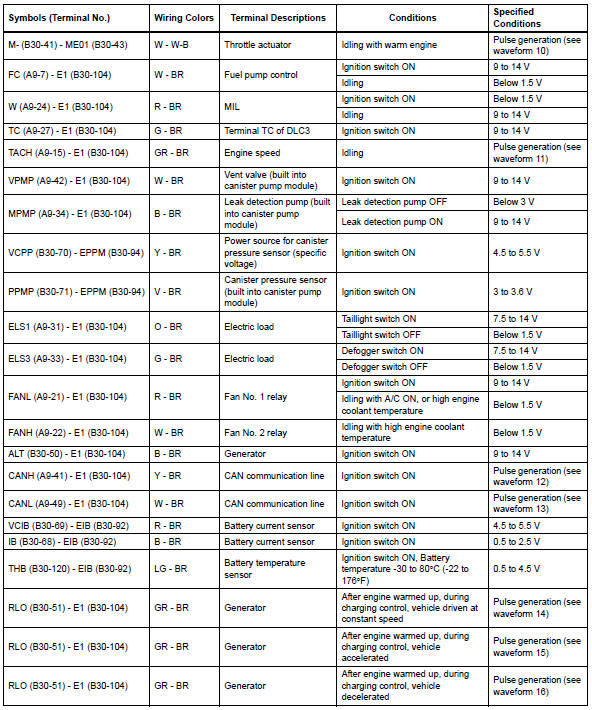

The standard normal voltage between each pair of ecm terminals is shown in the table below. The appropriate conditions for checking each pair of terminals are also indicated. The result of checks should be compared with the standard normal voltage for that pair of terminals, displayed in the specified condition column. The illustration above can be used as a reference to identify the ecm terminal locations.

Hint:

*: The ecm terminal voltage is constant regardless of the output voltage from the sensor.

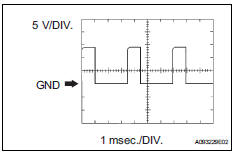

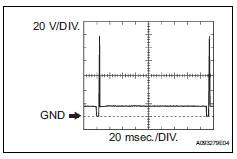

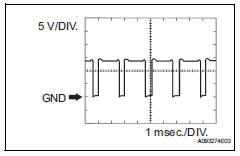

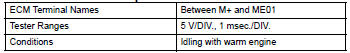

Waveform 1

Camshaft

Camshaft

timing oil control valve (ocv)

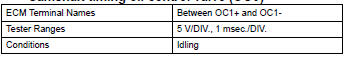

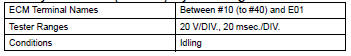

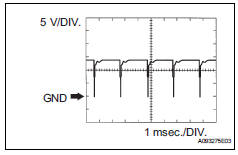

- Waveform 2

Heated oxygen

Heated oxygen

sensor

Hint:

In data list, item o2s b1 s2 shows the ecm input values from the heated oxygen sensor.

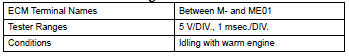

- Waveform 3

Injector no.

Injector no.

1 (To no. 4) Injection signal

Hint:

The wavelength becomes shorter as the engine rpm increases.

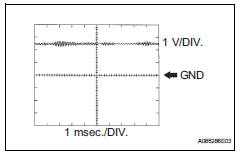

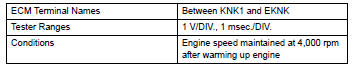

- Waveform 4

Knock sensor

Knock sensor

Hint:

- The wavelength becomes shorter as the engine rpm increases.

- The waveforms and amplitudes displayed differ slightly depending on the vehicle.

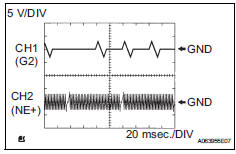

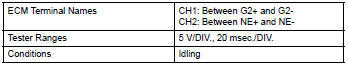

- Waveform 5

Crankshaft

Crankshaft

position sensor and camshaft position

sensor

Hint:

The wavelength becomes shorter as the engine rpm increases.

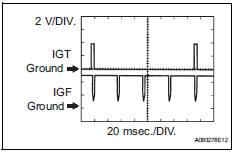

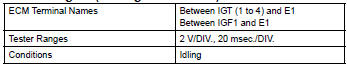

- Waveform 6

Igniter igt

Igniter igt

signal (from ecm to igniter) and igniter

igf signal (from igniter to ecm)

Hint:

The wavelength becomes shorter as the engine rpm increases.

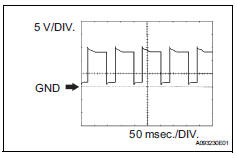

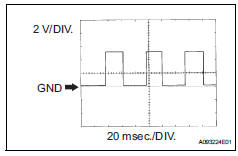

- Waveform 7

Purge vsv

Purge vsv

Hint:

If the waveform is not similar to the illustration, check the waveform again after idling for 10 minutes or more.

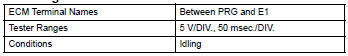

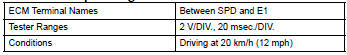

- Waveform 8

Vehicle speed

Vehicle speed

signal

Hint:

The wavelength becomes shorter as the vehicle speed increases.

- Waveform 9

Throttle

Throttle

actuator positive terminal

Hint:

The duty ratio varies depending on the throttle actuator operation.

- Waveform 10

Throttle

Throttle

actuator negative terminal

Hint:

The duty ratio varies depending on the throttle actuator operation.

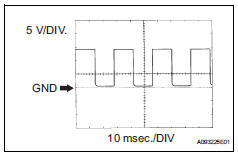

- Waveform 11

Engine speed

Engine speed

signal

Hint:

The wavelength becomes shorter as the engine rpm increases.

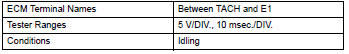

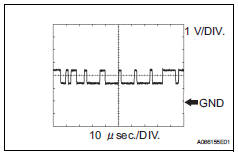

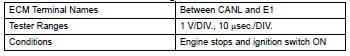

- Waveform 12

Can

Can

communication signal

Hint:

The waveform varies depending on the can communication signal.

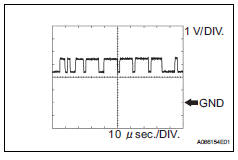

- Waveform 13

Can

Can

communication signal

Hint:

The waveform varies depending on the can communication signal.

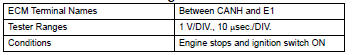

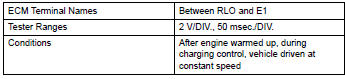

- Waveform 14

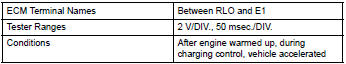

Generator

Generator

Hint:

A constant value is not output, as the duty ratio varies depending on the electrical load and battery condition.

- Waveform 15

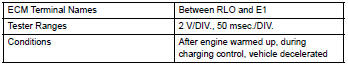

Generator

Generator

Hint:

A constant value is not output, as the duty ratio varies depending on the electrical load and battery condition.

- Waveform 16

Generator

Generator

Hint:

A constant value is not output, as the duty ratio varies depending on the electrical load and battery condition.

Problem symptoms table

Problem symptoms table

Hint:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms are

listed in order of probability in the "suspected area" column of

th ...

Diagnosis system

Diagnosis system

Description

When troubleshooting obd ii (on-board diagnostics)

vehicles, the intelligent tester (complying with sae

j1987) must be connected to the dlc3 (data link

connector 3) of the vehicle ...

Other materials:

Do-it-yourself service precautions

If you perform maintenance

by yourself, be sure to follow

the correct procedure

as given in these sections.

Maintenance

WARNING

The engine compartment contains

many mechanisms and fluids that

may move suddenly, become hot,

or become electrically energized.

To avoid death or serious injury,

obser ...

Compressor and pulley (for 2gr-fe)

Components

Removal

Discharge refrigerant from

refrigeration system (see page ac-172)

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensione ...

Rear occupant classification sensor rh circuit malfunction

Description

The rear occupant classification sensor rh circuit consists of the occupant

classification ecu and the

rear occupant classification sensor rh.

Dtc b1783 is recorded when a malfunction is detected in the rear occupant

classification sensor rh

circuit.

Wiring diagram

...