Toyota RAV4 (XA40) 2013-2018 Service Manual: Brake booster

Installation (2005/11-2006/01)

- Install check valve grommet

- Install the grommet to the booster.

- Install brake vacuum check valve assembly

- Install the check valve to the grommet.

- Install brake booster gasket

- Install a new gasket to the booster.

- Install brake master cylinder push rod clevis

- Install the push rod clevis to the booster.

- Temporarily tighten the push rod clevis lock nut.

Hint:

The push rod clevis lock nut will be tightened to a torque specification in the "check and adjust brake pedal height" procedures.

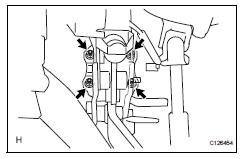

- Install brake booster assembly

- Install the booster with the 4 nuts.

Torque: 12.7 N*m (130 kgf*cm, 9 ft.*Lbf)

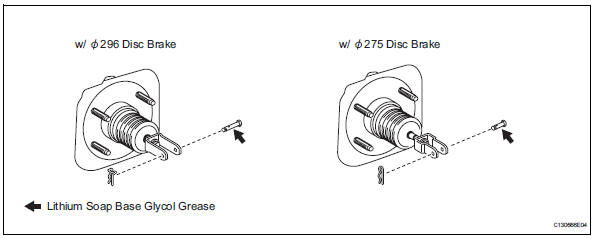

- Install push rod pin

- Apply lithium soap base glycol grease to the push rod pin.

- Install the push rod pin to the push rod clevis.

Notice:

The push rod pin must be installed as shown in the illustration.

- Install the clip to the push rod pin.

Notice:

The clip must be installed as shown in the illustration.

- Check and adjust brake booster push rod (see page br-24)

- Connect vacuum hose

- Connect the vacuum hose to the check valve.

- Install brake master cylinder subassembly (see page br-25)

- Install abs and traction actuator assembly with bracket (see page bc-186)

- Connect brake lines (see page bc-187)

- Fill reservoir with brake fluid (see page br- 6)

- Bleed air from brake master cylinder (see page br-7)

- Bleed air from brake line (see page br-7)

- Bleed air from abs and traction actuator assembly (see page br-8)

- Check and adjust brake pedal height (see page br-13)

- Check brake pedal free play (see page br- 14)

- Check brake pedal reserve distance (see page br-14)

- Check brake fluid level in reservoir (see page br-6)

- Check for brake fluid leakage

- Install air cleaner case sub-assembly

- Install the air cleaner case (see page em-105).

Hint:

Refer to the procedures from the installation of the air cleaner case up until the installation of the purge vsv.

Installation (2006/01- )

- Install check valve grommet

- Install the grommet to the booster.

- Install brake vacuum check valve assembly

- Install the check valve to the grommet.

- Install brake booster gasket

- Install a new gasket to the booster.

- Install brake master cylinder push rod clevis

- Install the push rod clevis to the booster.

- Temporarily tighten the push rod clevis lock nut.

Hint:

The push rod clevis lock nut will be tightened to a torque specification in the "check and adjust brake pedal height" procedures.

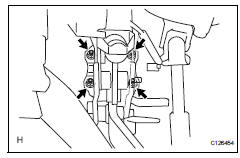

- Install brake booster assembly

- Install the booster with the 4 nuts.

Torque: 12.7 N*m (130 kgf*cm, 9 ft.*Lbf)

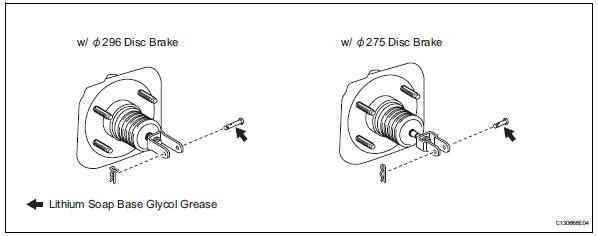

- Install push rod pin

- Apply lithium soap base glycol grease to the push rod pin.

- Install the push rod pin to the push rod clevis.

Notice:

The push rod pin must be installed as shown in the illustration.

- Install the clip to the push rod pin.

Notice:

The clip must be installed as shown in the illustration.

- Check and adjust brake booster push rod (see page br-24)

- Connect vacuum hose

- Connect the vacuum hose to the check valve.

- Install brake master cylinder subassembly (see page br-26)

- Install abs and traction actuator assembly with bracket (see page bc-187)

- Connect brake lines (see page bc-188)

- Fill reservoir with brake fluid (see page br- 6)

- Bleed air from brake master cylinder (see page br-7)

- Bleed air from brake line (see page br-7)

- Bleed air from abs and traction actuator assembly (see page br-8)

- Check and adjust brake pedal height (see page br-15)

- Check brake pedal free play (see page br- 15)

- Check brake pedal reserve distance (see page br-16)

- Check brake fluid level in reservoir (see page br-6)

- Check for brake fluid leakage

- Install air cleaner case sub-assembly (for 2az-fe)

- Install the air cleaner case (see page em-105).

Hint:

Refer to the procedures from the installation of the air cleaner case up until the installation of the purge vsv.

- Install air cleaner case (for 2gr-fe)

- Install the air cleaner case (see page em-31).

Hint:

Refer to the procedures from the installation of the air cleaner case up until the installation of the air cleaner cap sub-assembly.

Brake master cylinder

Brake master cylinder

Components

On-vehicle inspection

Check brake fluid level warning switch

Remove the reservoir filler cap and strainer.

Disconnect the brake fluid level warning switch

connector.

...

Front brake

Front brake

Components

Removal

Hint:

Use the same procedures for the lh side and rh side.

The procedures listed below are for the lh side.

Remove front wheel

Drain brake fluid

Notic ...

Other materials:

When closing the back door

Lower the back door using the

back door handle.

Vehicles without a power back

door

Make sure to push the back door

down from the outside to close it.

Vehicles with a power back

door

The back door closing assist will

activate, and the back door will

fully close automatically.

...

Unlocking and locking the doors

Front doors

Grip the driver’s door handle to

unlock the door. Grip the passenger’s

door handle to unlock all the

doors.*

Make sure to touch the sensor on

the back of the handle.

The doors cannot be unlocked for

3 seconds after the doors are

locked.

*: The door unlock settings can be ...

Opening the fuel tank cap

Pull up the opener to open the

fuel filler door.

Turn the fuel tank cap slowly to

open.

Hang the fuel tank cap on the

back of the fuel filler door.

...