Toyota RAV4 (XA40) 2013-2018 Service Manual: Disassembly (2005/11-2006/01)

- Remove front axle inboard joint boot no. 2 Clamp lh

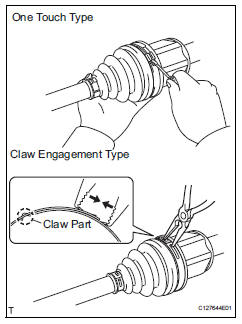

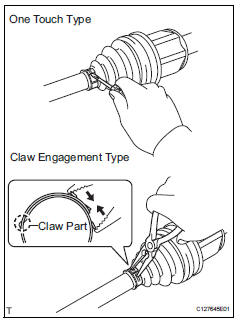

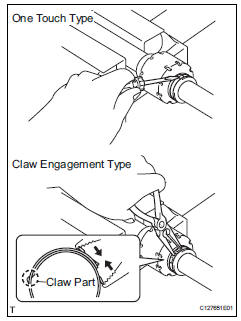

- One touch type:

- Using a screwdriver, remove the inboard joint boot clamp, as shown in the illustration.

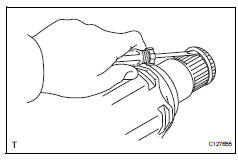

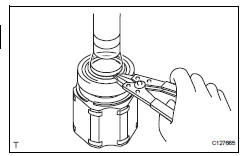

- Claw engagement type:

- Using needle-nose pliers, remove the inboard joint boot clamp, as shown in the illustration.

- Remove front axle inboard joint boot no. 2 Clamp rh

Hint:

Use the same procedures described for the lh side.

- Remove front axle inboard joint boot clamp lh

- One touch type:

- Using a screwdriver, remove the inboard joint boot clamp, as shown in the illustration.

- Claw engagement type:

Using needle-nose pliers, remove the inboard joint boot clamp, as shown in the illustration.

- Remove front axle inboard joint boot clamp rh

Hint:

Use the same procedures described for the lh side.

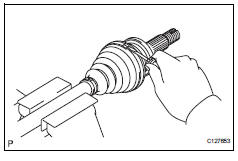

- Remove front axle inboard joint boot

- Remove the boot from the inboard joint.

- Remove front drive inboard joint assembly lh

- Remove any old grease from the inboard joint.

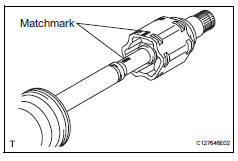

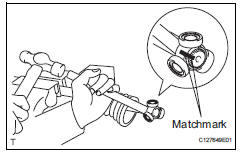

- Put matchmarks on the inboard joint and outboard joint shaft.

Notice:

Do not punch the marks.

- Remove the inboard joint from the outboard joint shaft.

- Using a snap ring expander, remove the shaft snap ring.

- Put matchmarks on the outboard joint shaft and tripod joint.

Notice:

Do not punch the marks.

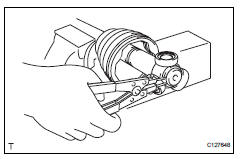

- Using a brass bar and hammer, tap out the tripod joint from the outboard joint shaft.

Notice:

Do not tap the rollers.

- Remove the inboard joint boot.

- Remove front drive shaft damper clamp lh

- One touch type:

- Using a screwdriver, remove the drive shaft damper clamp, as shown in the illustration.

- Claw engagement type:

Using needle-nose pliers, remove the drive shaft damper clamp, as shown in the illustration.

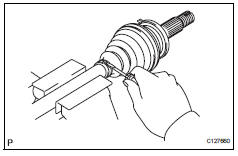

- Remove front drive shaft damper lh

- Remove the front drive shaft damper from the outboard joint shaft.

- Remove front axle outboard joint boot no. 2 Clamp lh

- Using a screwdriver, remove the outboard joint boot clamp, as shown in the illustration.

- Remove front axle outboard joint boot clamp lh

- Using a screwdriver, remove the outboard joint boot clamp, as shown in the illustration.

- Remove front axle outboard joint boot

- Remove the outboard joint boot from the outboard joint shaft.

- Remove any old grease from the outboard joint.

- Remove front drive shaft hole snap ring lh

- Using a screwdriver, remove the hole snap ring.

- Remove front drive shaft dust cover lh

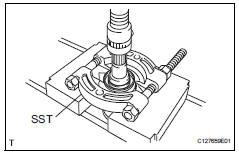

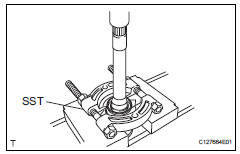

- Using sst and a press, press out the shaft dust cover

Sst 09950-00020

Notice:

Be careful not to drop the inboard joint

- Remove front drive shaft dust cover rh

Hint:

Use the same procedures described for the lh side.

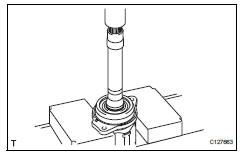

- Remove drive shaft bearing case

- Using a screwdriver, remove the bearing case snap ring.

- Using a press, press out the drive shaft bearing case.

Hint:

Be careful not to drop the inboard joint

- Remove front drive shaft dust cover

- Using sst and a press, press out the drive shaft dust cover.

Sst 09950-00020

Hint:

Be careful not to drop the inboard joint

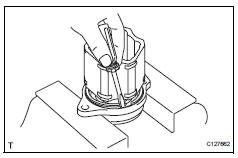

- Remove front drive shaft bearing

- Using a snap ring expander, remove the snap ring.

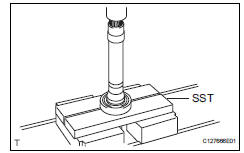

- Using sst and a press, press out the drive shaft bearing.

Sst 09527-10011

- Remove the snap ring.

Removal

(2006/01- )

Removal

(2006/01- )

Remove front wheel

Drain automatic transaxle fluid

Drain the automatic transaxle fluid for u140f (see

page ax-147).

Drain the automatic transaxle fluid for u241e (see

page ax-146).

...

Disassembly (2006/01- )

Disassembly (2006/01- )

Remove front axle inboard joint boot no. 2 Clamp

One touch type:

using a screwdriver, remove the inboard joint boot

clamp, as shown in the illustration.

Claw engagement type:

usin ...

Other materials:

Cruise control

Summary of functions

Use the cruise control to maintain a set speed without depressing the

accelerator pedal.

Indicators

Cruise control switch

Setting the vehicle speed

Press the “on-off” button to

activate the cruise control.

Cruise control indicator will come

on.

...

Outer mirror switch

Inspection

Inspect outer mirror switch assembly

The l position of the left/right adjustment switch:

measure the resistance of the mirror switch.

Standard resistance (for left side)

If the result is not as specified, replace the switch

assembly.

The r position of the left/r ...

Oxygen (a/f) sensor signal stuck

Hint:

Although the dtc titles say oxygen sensor, these dtcs relate to the

air-fuel ratio (a/f) sensor.

Sensor 1 refers to the sensor mounted in front of the three-way

catalytic converter (twc) and

located near the engine assembly.

Description

The a/f sensor generates a voltage* ...