Toyota RAV4 (XA40) 2013-2018 Service Manual: Disassembly (2006/01- )

- Remove front axle inboard joint boot no. 2 Clamp

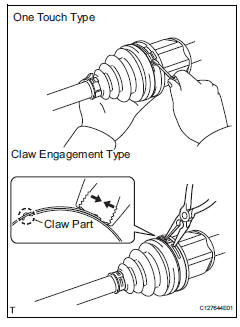

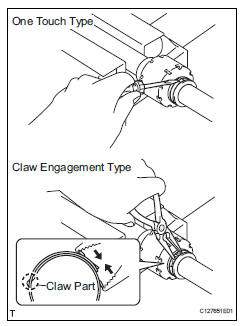

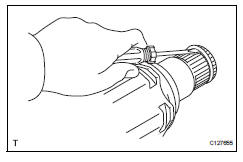

- One touch type: using a screwdriver, remove the inboard joint boot clamp, as shown in the illustration.

- Claw engagement type: using needle-nose pliers, remove the inboard joint boot clamp, as shown in the illustration.

- Remove front axle inboard joint boot clamp

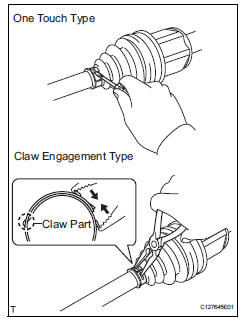

- One touch type: using a screwdriver, remove the inboard joint boot clamp, as shown in the illustration.

- Claw engagement type: using needle-nose pliers, remove the inboard joint boot clamp, as shown in the illustration.

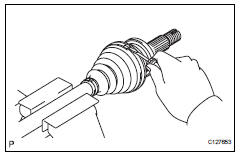

- Remove front axle inboard joint boot

- Remove the boot from the inboard joint.

- Remove front drive inboard joint assembly lh

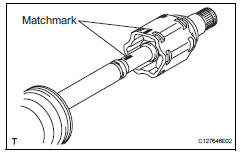

- Remove any old grease from the inboard joint.

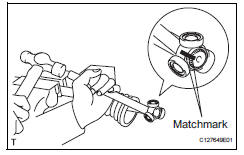

- Put matchmarks on the inboard joint and outboard joint shaft.

Notice:

Do not punch the marks.

- Remove the inboard joint from the outboard joint shaft.

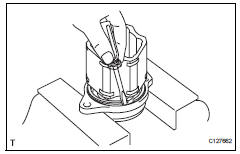

- Using a snap ring expander, remove the shaft snap ring.

- Put matchmarks on the outboard joint shaft and tripod joint.

Notice:

Do not punch the marks.

- Using a brass bar and hammer, tap out the tripod joint from the outboard joint shaft.

Notice:

Do not tap the rollers.

- Remove the inboard joint boot.

- Remove front drive inboard joint assembly rh

Hint:

Use the same procedures described for the lh side.

- Remove front drive shaft damper clamp lh

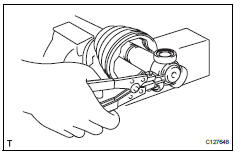

- One touch type: using a screwdriver, remove the drive shaft damper clamp, as shown in the illustration.

- Claw engagement type: using needle-nose pliers, remove the drive shaft damper clamp, as shown in the illustration.

- Remove front drive shaft damper lh

- Remove the front drive shaft damper from the outboard joint shaft.

- Remove front axle outboard joint boot no. 2 Clamp

- Using a screwdriver, remove the outboard joint boot clamp, as shown in the illustration.

- Remove front axle outboard joint boot clamp

- Using a screwdriver, remove the outboard joint boot clamp, as shown in the illustration.

- Remove front axle outboard joint boot

- Remove the outboard joint boot from the outboard joint shaft.

- Remove any old grease from the outboard joint.

- Remove front drive shaft hole snap ring lh

- Using a screwdriver, remove the hole snap ring.

- Remove front drive shaft dust cover lh

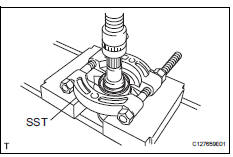

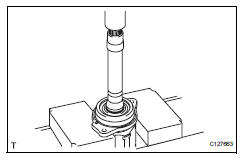

- Using sst and a press, press out the shaft dust cover.

Sst 09950-00020

Notice:

Be careful not to drop the inboard joint.

- Remove front drive shaft dust cover rh

Hint:

Use the same procedures described for the lh side.

- Remove drive shaft bearing case (for rh)

- Using a screwdriver, remove the bearing case snap ring.

- Using a press, press out the drive shaft bearing case.

Hint:

Be careful not to drop the inboard joint.

- Remove front drive shaft dust cover (for rh)

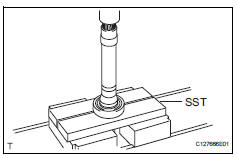

- Using sst and a press, press out the drive shaft dust cover.

Sst 09950-00020

Notice:

Be careful not to drop the inboard joint.

- Remove front drive shaft bearing

- Using a snap ring expander, remove the snap ring.

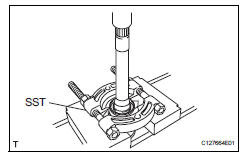

- Using sst and a press, press out the drive shaft bearing.

Sst 09527-10011

- Remove the bearing case snap ring.

Disassembly (2005/11-2006/01)

Disassembly (2005/11-2006/01)

Remove front axle inboard joint boot no. 2 Clamp lh

One touch type:

Using a screwdriver, remove the inboard joint

boot clamp, as shown in the illustration.

Claw engagement t ...

Reassembly (2005/11-2006/01)

Reassembly (2005/11-2006/01)

Install drive shaft bearing case subassembly

Using sst and a press, press in the drive shaft

bearing case to the inboard joint rh.

Sst 09527-10011, 09710-04081

Notice:

The bearing ...

Other materials:

Pressure sensor circuit

Description

This dtc is output when the refrigerant pressure is either extremely low

(0.19 Mpa [2.0 Kgf/cm2, 28 psi]

or less) or extremely high (3.14 Mpa [32.0 Kgf/cm2, 455 psi] or more). The air

conditioning pressure

sensor, which is installed on the pipe of the high pressure side, detec ...

Front occupant classification sensor rh collision detection

Description

Dtc b1786 is output when the occupant classification ecu receives a collision

detection signal sent by

the front occupant classification sensor rh when an accident occurs.

Dtc b1786 is also output when the front seat assembly rh is subjected to a

strong impact, even if an

a ...

Installation

Hint:

Use the same procedures for the rh side and lh side.

The procedures listed below are for the lh side.

Install no. 2 Seat leg box protector

Attach the clip to install the protector.

Install the clip.

Install rear no. 1 Floor mat support side plate

Install rear no ...