Toyota RAV4 (XA40) 2013-2018 Service Manual: Disassembly (2006/01- )

- Remove front axle inboard joint boot no. 2 Clamp

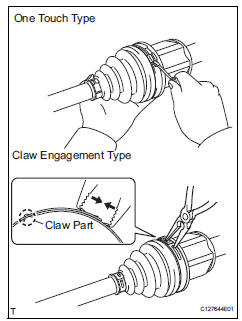

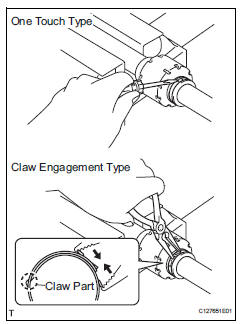

- One touch type: using a screwdriver, remove the no. 2 Inboard joint boot clamp, as shown in the illustration.

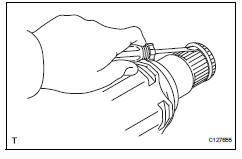

- Claw engagement type: using needle-nose pliers, remove the no. 2 Inboard joint boot clamp, as shown in the illustration.

- Remove front axle inboard joint boot clamp

- One touch type: using a screwdriver, remove the inboard joint boot clamp, as shown in the illustration.

- Claw engagement type: using needle-nose pliers, remove the inboard joint boot clamp, as shown in the illustration.

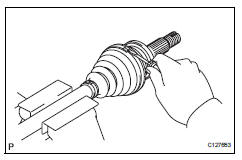

- Remove front axle inboard joint boot

- Remove the boot from the inboard joint.

- Remove front drive inboard joint assembly lh

- Remove any old grease from the inboard joint.

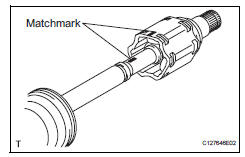

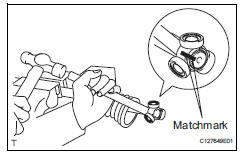

- Put matchmarks on the inboard joint and outboard joint shaft.

Notice:

Do not punch the marks.

- Remove the inboard joint from the outboard joint shaft.

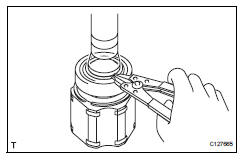

- Using a snap ring expander, remove the shaft snap ring.

- Put matchmarks on the outboard joint shaft and tripod joint.

Notice:

Do not punch the marks.

- Using a brass bar and hammer, tap out the tripod joint from the outboard joint shaft.

Notice:

Do not tap the rollers.

- Remove the inboard joint boot.

- Remove front drive shaft inboard joint assembly rh

Hint:

Use the same procedures described for the lh side.

- Remove front drive shaft damper clamp lh

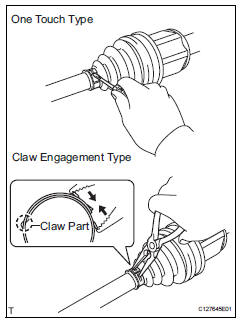

- One touch type: using a screwdriver, remove the drive shaft damper clamp, as shown in the illustration.

- Claw engagement type: using needle-nose pliers, remove the drive shaft damper clamp, as shown in the illustration.

- Remove front drive shaft damper lh

- Remove the front drive shaft damper

- Remove front drive shaft damper clamp rh

Hint:

Use the same procedures described for the lh side.

- Remove front drive shaft damper rh

Hint:

Use the same procedures described for the lh side.

- Remove front axle outboard joint boot no. 2 Clamp

- Using a screwdriver, remove the no. 2 Outboard joint boot clamp, as shown in the illustration.

- Remove front axle outboard joint boot clamp

- Using a screwdriver, remove the outboard joint boot clamp, as shown in the illustration.

- Remove front axle outboard joint boot

- Remove the outboard joint boot from the outboard joint shaft.

- Remove any old grease from the outboard joint.

- Remove front drive shaft hole snap ring lh

- Using a screwdriver, remove the hole snap ring.

- Remove front drive shaft dust cover lh

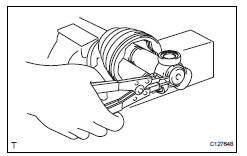

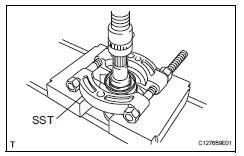

- Using sst and a press, press out the front drive shaft dust cover.

Sst 09950-00020

Notice:

Be careful not to drop the inboard joint.

- Remove front drive shaft dust cover rh

Hint:

Use the same procedures described for the lh side.

- Remove front drive shaft bearing (for rh)

- Using a snap ring expander, remove the drive shaft hole snap ring.

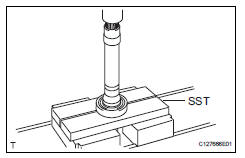

- Using sst and a press, press out the drive shaft bearing.

Sst 09527-10011

- Remove the bearing bracket snap ring.

Disassembly (2005/11-2006/01)

Disassembly (2005/11-2006/01)

Remove front axle inboard joint boot no. 2

Clamp lh

One touch type:

Using a screwdriver, remove the no. 2 Inboard

joint boot clamp, as shown in the illustration.

Claw eng ...

Reassembly (2005/11-2006/01)

Reassembly (2005/11-2006/01)

Install front drive shaft bearing

Using sst and a press, press in the drive shaft

bearing to the inboard joint rh.

Sst 09527-10011, 09710-04081

Notice:

The bearing should be instal ...

Other materials:

Installation

Hint:

Use the same procedures for the rh side and lh side.

The procedures listed below are for the lh side.

Install front door belt moulding

assembly lh

Attach the claws to install the belt moulding.

Hint:

Confirm that the moulding is firmly installed.

Install outer r ...

Registering a bluetooth®

device

Bluetooth® compatible phones (hfp) and portable audio players

(avp) can be registered simultaneously. You can register up to 5

bluetooth® devices.

How to register a bluetooth® device

Display the “bluetooth* setup” screen.

*: Bluetooth is a registered trademark of bluetooth sig, inc. ...

Vsc warning light does not come on

Description

Refer to the description of "vsc warning light remains on" (see page bc-139).

Wiring diagram

Refer to the vsc warning light circuit (see page bc-140).

Inspection procedure

Notice:

When replacing the abs and traction actuator, perform the zero point

calibration (see page ...