Toyota RAV4 (XA40) 2013-2018 Service Manual: Front suspension lower no. 1 Arm

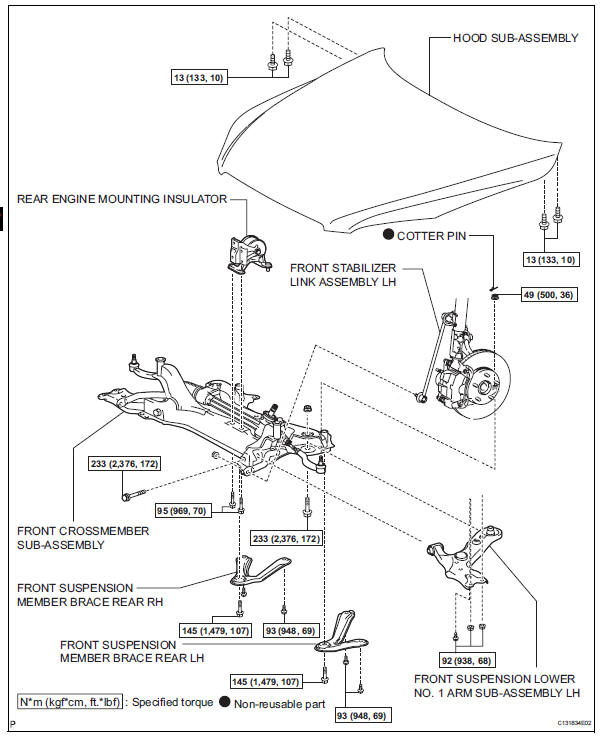

Components

Removal

- Remove front wheel

- Remove hood sub-assembly

- Remove the hood (see page ed-4).

- Suspend engine assembly

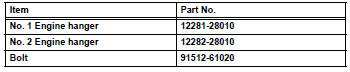

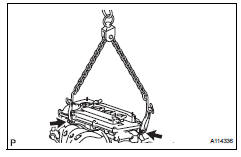

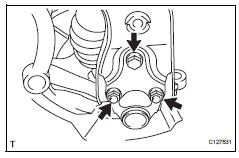

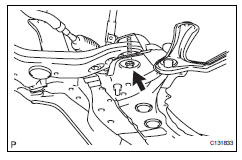

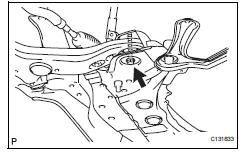

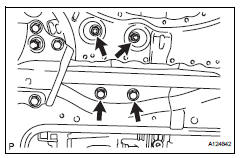

- Install the no. 1 And no. 2 Engine hangers with the bolts as shown in the illustration.

Torque: 38 n*m (387 kgf*cm, 28 ft.*Lbf)

parts no.

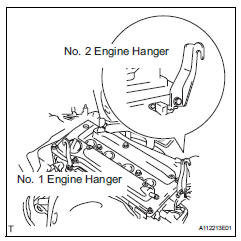

- Attach the sling device and the engine with the chain block.

- Disconnect front stabilizer link assembly lh (see page sp-30)

- Disconnect front stabilizer link assembly rh

- Use the same procedure described for the lh side.

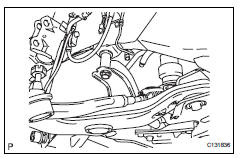

- Disconnect front suspension lower no. 1 Arm sub-assembly lh

- Remove the 2 nuts and bolt, and disconnect the lower arm from the ball joint.

- Disconnect front suspension lower no. 1 Arm sub-assembly rh

Hint:

Use the same procedures described for the lh side.

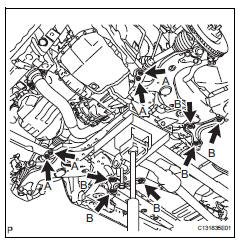

- Disconnect front crossmember subassembly

- Remove the 2 nuts, 2 bolts and engine mounting insulator rear.

- Remove the bolt from the suspension member.

- Support the crossmember with the jack.

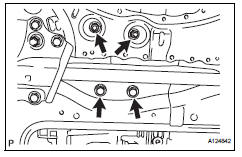

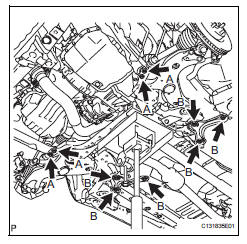

- Remove the bolts labeled a.

- Remove the 4 bolts from the member reinforcement.

- Remove the bolts labeled b.

- Remove the 6 bolts from the member brace.

- Slowly lower the jack, and disconnect the crossmember from the vehicle.

- Remove front suspension lower no. 1 Arm sub-assembly lh

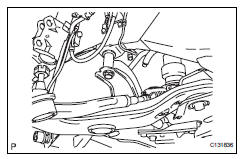

- Remove the bolt and nut from the suspension member (front side).

- Remove the bolt and nut from the suspension member (rear side). Then remove the lower arm.

- Remove front suspension lower no. 1 Arm sub-assembly rh

Hint:

Use the same procedures described for the lh side.

Installation

- Temporarily install front suspension lower no. 1 Arm lh

- Temporarily install the lower arm with the bolt and nut to the front side.

- Temporarily install the lower arm with the bolt and nut to the rear side.

- Temporarily install front suspension no. 1 Lower arm sub-assembly rh

Hint:

Use the same procedures described for the lh side.

- Connect front crossmember subassembly

- Slowly raise the crossmember jack, and connect the crossmember to the body.

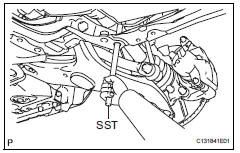

- Using sst, align the holes of the suspension member and body.

Sst 09670-00020

- Perform the procedure above on the other side.

- Install the member reinforcement with the 4 bolts labeled a.

- Install the suspension member brace with the 6 bolts labeled b.

- Install the suspension member with the bolt to the body.

- Perform the procedure above on the other side.

- Install the engine mounting insulator rear with the 2 nuts and 2 bolts.

- Install front stabilizer link assembly lh (see page sp-30)

- Connect front suspension lower no. 1 Arm sub-assembly lh

- Connect the lower arm with the 2 bolts and nut to the ball joint.

Torque: 92 n*m (938 kgf*cm, 68 ft.*Lbf)

- Install front wheel

Torque: 103 n*m (1,050 kgf*cm, 76 ft.*Lbf)

- Stabilize suspension (see page sp-12)

- Tighten front cross member sub-assembly

- Tighten the bolts and nuts.

Torque: 87 n*m (887 kgf*cm, 64 ft.*Lbf) for bolt a

93 N*m (948 kgf*cm, 69 ft.*Lbf) for bolt b

145 N*m (1,479 kgf*cm, 107 ft.*Lbf) for body

95 N*m (969 kgf*cm, 70 ft.*Lbf) for engine mounting insulator

- Tighten front suspension lower no. 1 Arm sub-assembly lh

- Using sst, and tighten the bolt on the front side.

Sst 09961-01270

Torque: 223 n*m (2,376 kgf*cm, 172 ft.*Lbf) for use without sst

175 N*m (1,785 kgf*cm, 129 ft.*Lbf) for use with sst

Notice:

Do not tighten the nut.

- Fix the nut in place and tighten the bolt on the rear side.

Torque: 223 n*m (2,376 kgf*cm, 172 ft.*Lbf)

Notice:

Do not tighten the nut.

- Tighten front suspension lower no. 1 Arm sub-assembly rh

Hint:

Use the same procedures described for the lh side.

- Install hood sub-assembly (see page ed-7)

- Inspect and adjust hood sub-assembly

- Inspect and adjust the hood (see page ed-5).

- Inspect and adjust front wheel alignment

- Inspect and adjust the front wheel alignment (see page sp-3).

Suspension & axle front shock absorber with coil spring (for sport package)

Suspension & axle front shock absorber with coil spring (for sport package)

Components

Removal

Hint:

Use the same procedures for the rh side and lh side.

The procedures listed below are for the lh side.

Remove front wheel

Remove front speed sensor lh (see ...

Front lower ball joint

Front lower ball joint

Components

Removal

Hint:

Use the same procedures for the rh side and lh side.

The procedures listed below are for the lh side.

Remove front wheel

Remove front speed sensor lh (for ...

Other materials:

Compressor and pulley (for 2az-fe)

Components

Removal

Discharge refrigerant from

refrigeration system (see page ac-172)

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensione ...

Trailer tongue weight

A recommended tongue weight varies in accordance with the types

of trailers or towing as described below.

To ensure the recommended values shown below, the trailer must

be loaded by referring to the following instructions.

Tongue weight

The gross trailer weight should be distributed so ...

Camshaft position sensor "a" circuit (bank 1 or single sensor)

Description

The camshaft position (cmp) sensor consists of a magnet and an iron core

which is wrapped with copper

wire, and is installed onto the cylinder head. When the camshaft rotates, each

of 3 teeth on the camshaft

passes through the cmp sensor. This activates the internal magnet in ...