Toyota RAV4 (XA40) 2013-2018 Service Manual: Compressor and pulley (for 2az-fe)

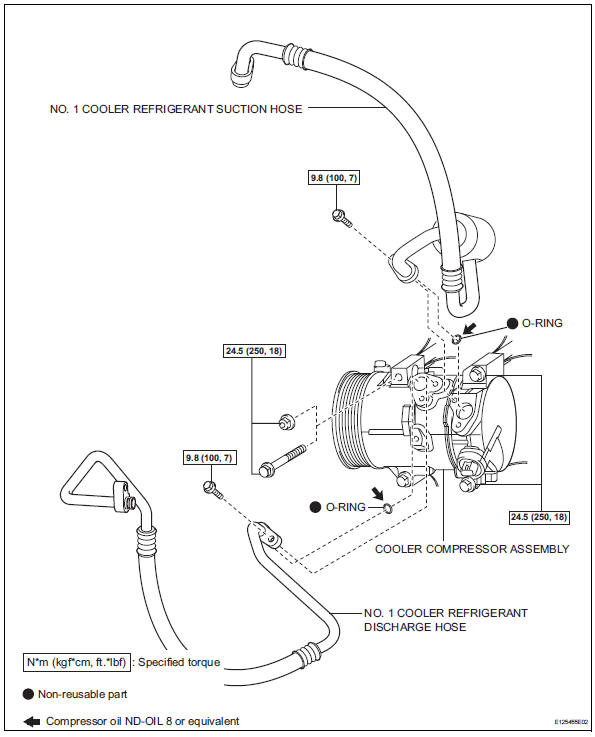

Components

Removal

- Discharge refrigerant from refrigeration system (see page ac-172)

- Disconnect cable from negative battery terminal

Caution:

Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to prevent airbag and seat belt pretensioner activation.

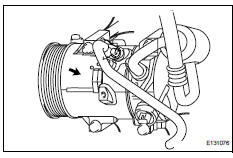

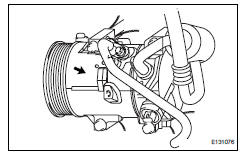

- Disconnect no. 1 Cooler refrigerant suction hose

- Remove the bolt and disconnect the cooler refrigerant suction hose from the cooler compressor.

- Remove the o-ring from the cooler refrigerant suction hose.

Notice:

Seal the openings of the disconnected parts using vinyl tape to prevent moisture and foreign matter from entering them.

- Disconnect no. 1 Cooler refrigerant discharge hose

- Remove the bolt and disconnect the cooler refrigerant discharge hose from the cooler compressor.

- Remove the o-ring from the cooler refrigerant discharge hose.

Notice:

Seal the openings of the disconnected parts using vinyl tape to prevent moisture and foreign matter from entering them.

- Remove no. 1 Engine under cover

- Remove fan and generator v belt (see page em-6)

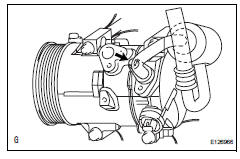

- Remove cooler compressor assembly

- Disconnect the connector.

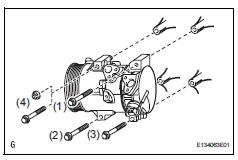

- W/o stud bolt: remove the 4 bolts and cooler compressor.

- W/ stud bolt: remove the 3 bolts, nut and cooler compressor.

Installation

- Adjust adjust compressor oil

- When replacing the compressor and magnetic clutch with a new one, gradually discharge the refrigerant gas from the service valve, and drain the following amount of oil from the new compressor and magnetic clutch before installation.

Standard: (oil capacity inside the new compressor and magnetic clutch: 130 + 15 cc (4.6 + 0.51 Fl.Oz.) ) -(Remaining oil amount in the removed compressor and magnetic clutch) = (oil amount to be removed from the new compressor when replacing)

Notice:

- When checking the compressor oil level, observe the precautions on the cooler removal/installation.

- If a new compressor and magnetic clutch is installed without removing some oil remaining in the pipes of the vehicle, the oil amount will be too large. This prevents heat exchange in the refrigerant cycle and causes refrigerant failure.

- If the volume of oil remaining in the removed compressor and magnetic clutch is too small, check for oil leakage.

- Be sure to use nd-oil 8 or equivalent for compressor oil.

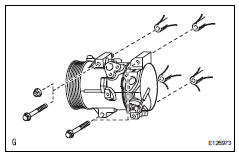

- Install cooler compressor assembly

- W/o stud bolt:

install the cooler compressor with the 4 bolts.

Torque: 24.5 N*m (250 kgf*cm, 18 ft.*Lbf)

Notice:

Tighten the bolts in the order shown in the illustration to install the cooler compressor.

- W/ stud bolt:

install the cooler compressor with the 3 bolts and

nut.

Torque: 24.5 N*m (250 kgf*cm, 18 ft.*Lbf)

Notice:

Tighten the bolts in the order shown in the illustration to install the cooler compressor.

- Connect the connector.

- Install no. 1 Cooler refrigerant discharge hose

- Remove the attached vinyl tape from the hose.

- Sufficiently apply compressor oil to a new o-ring and the fitting surface of the cooler compressor.

Compressor oil: nd-oil 8 or equivalent

- Install the o-ring on the cooler refrigerant discharge hose.

- Install the cooler refrigerant discharge hose on the

cooler compressor with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*Lbf)

- Install no. 1 Cooler refrigerant suction hose

- Remove the attached vinyl tape from the hose.

- Sufficiently apply compressor oil to a new o-ring and the fitting surface of the cooler compressor.

Compressor oil: nd-oil 8 or equivalent

- Install the o-ring on the cooler refrigerant suction hose.

- Install the cooler refrigerant suction hose on the cooler compressor with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*Lbf)

- Install fan and generator v belt (see page em-7)

- Install no. 1 Engine under cover

- Connect cable to negative battery terminal

- Charge refrigerant (see page ac-172)

- Warm up engine (see page ac-173)

- Check for leakage of refrigerant (see page ac-173)

Air mix control servo motor (for automatic air conditioning system)

Air mix control servo motor (for automatic air conditioning system)

Components

Removal

Remove air conditioning unit

Remove the air conditioning radiator (see page ac-

185).

Remove air mix control servo motor (see

page ac-191)

Inspection

...

Compressor and pulley (for 2gr-fe)

Compressor and pulley (for 2gr-fe)

Components

Removal

Discharge refrigerant from

refrigeration system (see page ac-172)

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconne ...

Other materials:

Purpose of readiness tests

The on-board diagnostic (obd ii) system is designed to

monitor the performance of emission related components,

and indicate any detected abnormalities with dtc

(diagnostic trouble codes). Since various components

need to be monitored during different driving conditions,

the obd ii syste ...

Light bulbs

You may replace the following bulbs by yourself. The difficulty

level of replacement varies depending on the bulb. If necessary

bulb replacement seems difficult to perform, contact your

toyota dealer.

For more information about replacing other light bulbs, contact

your toyota dealer.

Prepari ...

System diagram

System diagram (2005/11-2006/01)

System diagram (2006/01- )

...