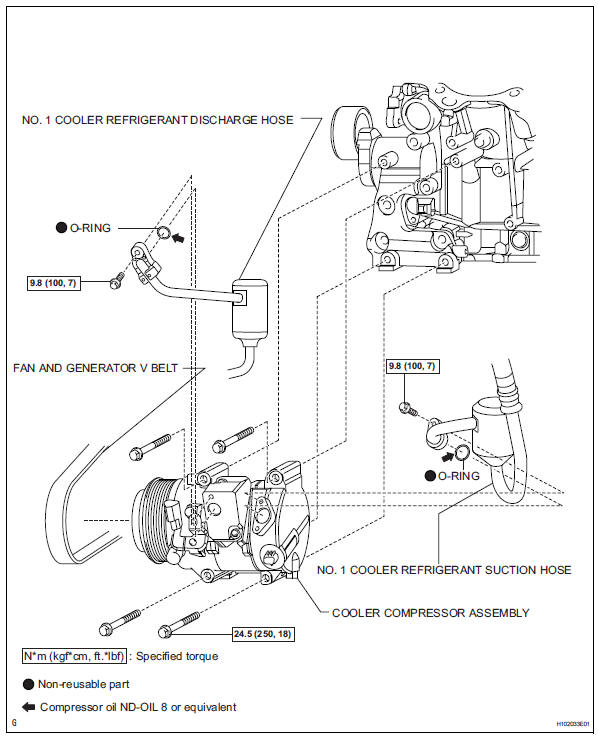

Toyota RAV4 (XA40) 2013-2018 Service Manual: Compressor and pulley (for 2gr-fe)

Components

Removal

- Discharge refrigerant from refrigeration system (see page ac-172)

- Disconnect cable from negative battery terminal

Caution:

Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to prevent airbag and seat belt pretensioner activation.

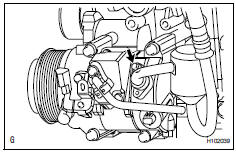

- Disconnect no. 1 Cooler refrigerant suction hose

- Remove the bolt and disconnect the cooler refrigerant suction hose from the cooler compressor.

- Remove the o-ring from the cooler refrigerant suction hose.

Notice:

Seal the openings of the disconnected parts using vinyl tape to prevent moisture and foreign matter from entering them.

- Disconnect no. 1 Cooler refrigerant discharge hose

- Remove the bolt and disconnect the cooler refrigerant discharge hose from the cooler compressor.

- Remove the o-ring from the cooler refrigerant discharge hose.

Notice:

Seal the openings of the disconnected parts using vinyl tape to prevent moisture and foreign matter from entering them.

- Remove fan and generator v belt (see page em-8)

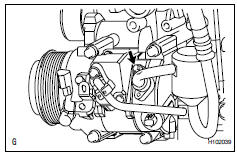

- Remove cooler compressor assembly

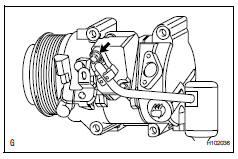

- Disconnect the connector.

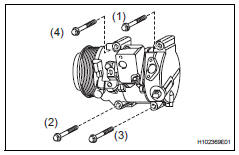

- Remove the 4 bolts and cooler compressor.

Installation

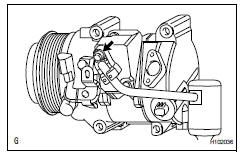

- Install cooler compressor assembly

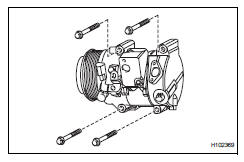

- Install the cooler compressor with the 4 bolts.

Torque: 24.5 N*m (250 kgf*cm, 18 ft.*Lbf)

Notice:

Tighten the bolts in the order shown in the illustration to install the cooler compressor.

- Connect the connector.

- Connect no. 1 Cooler refrigerant discharge hose

- Remove the attached vinyl tape from the hose.

- Sufficiently apply compressor oil to a new o-ring and the fitting surface of the cooler compressor.

Compressor oil: nd-oil 8 or equivalent

- Install the o-ring to the cooler refrigerant discharge hose.

- Connect the cooler refrigerant discharge hose to the cooler compressor with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*Lbf)

- Connect no. 1 Cooler refrigerant suction hose

- Remove the attached vinyl tape from the hose.

- Sufficiently apply compressor oil to a new o-ring and the fitting surface of the cooler compressor.

Compressor oil: nd-oil 8 or equivalent

- Install the o-ring to the cooler refrigerant suction hose.

- Connect the cooler refrigerant suction hose to the cooler compressor with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*Lbf)

- Install fan and generator v belt (see page em-8)

- Connect cable to negative battery terminal

- Charge refrigerant (see page ac-172)

- Warm up engine (see page ac-173)

- Check for leakage of refrigerant (see page ac-173)

Compressor and pulley (for 2az-fe)

Compressor and pulley (for 2az-fe)

Components

Removal

Discharge refrigerant from

refrigeration system (see page ac-172)

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconne ...

Condenser

Condenser

Components

On-vehicle inspection

Inspect cooler condenser assembly

If the fins of the cooler condenser are dirty, clean

them with water. Dry the fins with compressed air.

Notic ...

Other materials:

Blower resistor

On-vehicle inspection

Inspect blower motor control

Measure the resistance of the blower resistor.

Standard resistance

If the resistance is not as specified, replace the

blower motor control. ...

Brake switch "B" circuit high

Description

The purpose of this circuit is to prevent the engine from stalling while

driving in the lock-up condition when

the brakes are suddenly applied.

When the brake pedal is depressed, this switch sends a signal to the ecm. Then

the ecm cancels the

operation of the lock-up clutch ...

Components

...