Toyota RAV4 (XA40) 2013-2018 Service Manual: Evaporative emission leak detection pump

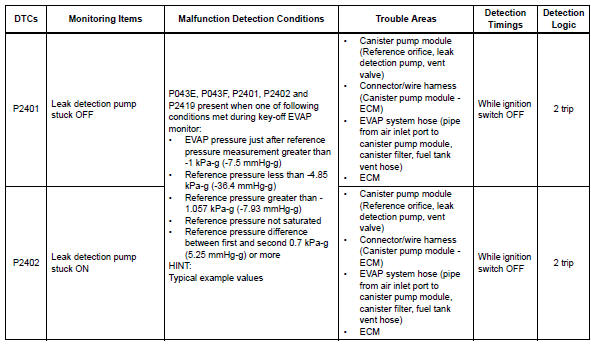

Dtc summary

Hint:

The leak detection pump is built into the canister pump module.

Description

The description can be found in the evap (evaporative emission) system (see page es-335).

Inspection procedure

Refer to the evap system (see page es-340).

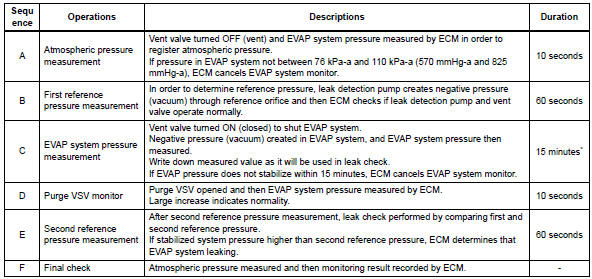

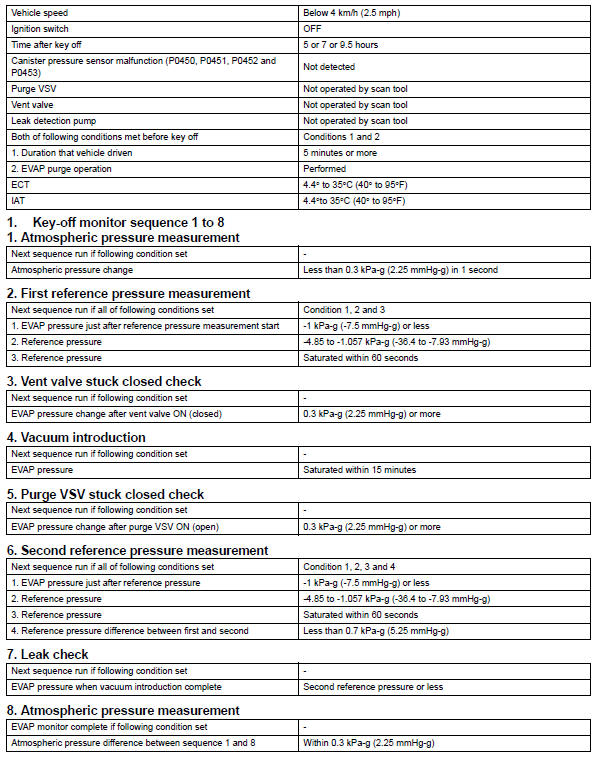

Monitor description

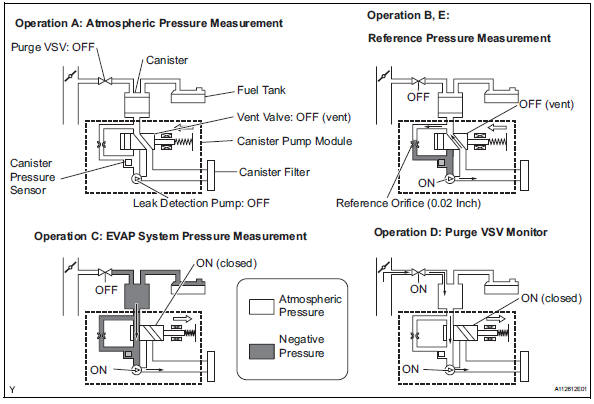

5 Hours* after the ignition switch is turned off, the leak detection pump creates negative pressure (vacuum) in the evap system. The ecm monitors for leaks and actuator malfunctions based on the evap pressure.

Hint:

*: If the engine coolant temperature is not below 35°c (95°f) 5 hours after the ignition switch is turned off, the monitor check starts 2 hours later. If it is still not below 35°c (95°f) 7 hours after the ignition switch is turned to off, the monitor check starts 2.5 Hours later.

![]()

*: If only a small amount of fuel is in the fuel tank, it takes longer for the evap pressure to stabilize.

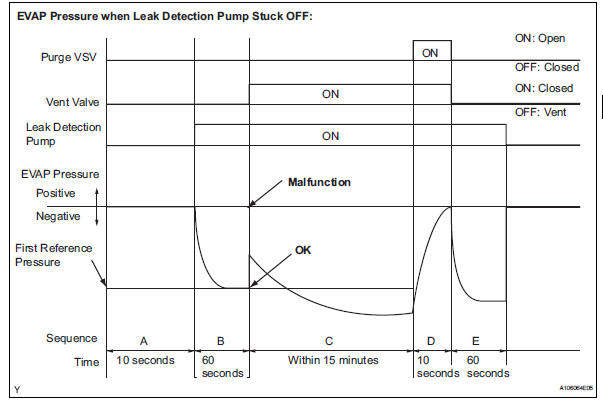

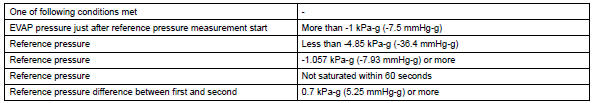

- P2401: leak detection pump stuck off in operation b, the leak detection pump creates negative pressure (a vacuum) through the reference orifice. The evap system pressure is then measured by the ecm, using the canister pressure sensor, to determine the reference pressure. If the pressure is higher than -1.057 Kpa-g (-7.93 Mmhg-g), or lower than -4.85 Kpa-g (-36.4 Mmhg-g), the ecm interprets this as the leak detection pump being stuck off (not operating). The ecm illuminates the mil and sets the dtc (2 trip detection logic).

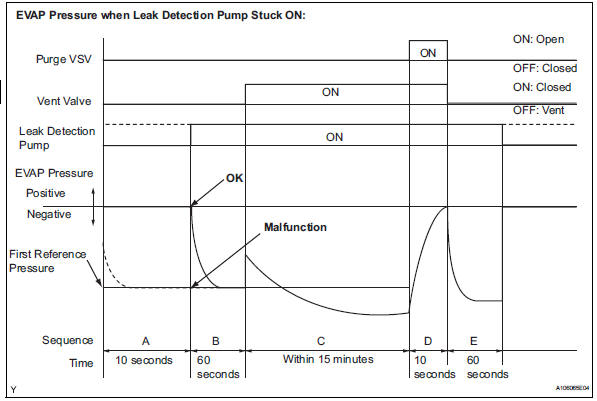

- P2402: leak detection pump stuck on in operation b, the leak detection pump creates negative pressure (a vacuum) through the reference orifice. The evap (evaporative emission) system pressure is then measured by the ecm, using the canister pressure sensor, to determine the reference pressure. If the pressure is higher than -1.057 Kpa-g (-7.93 Mmhg-g), or lower than -4.85 Kpa-g (-36.4 Mmhg-g), the ecm interprets this as the leak detection pump being stuck on (remaining on all the time). The ecm illuminates the mil and sets the dtc (2 trip detection logic).

Hint:

The detection logic of dtcs p2401 and p2402 is the same because in both cases the reference pressure measured in operation b is compared to the atmospheric pressure registered in operation a.

The ecm calculates the difference between these pressures by deducting [the reference pressure] from [the stored atmospheric pressure], and uses this to monitor the evap system pressure change.

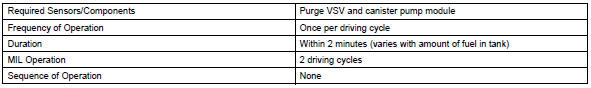

Monitor strategy

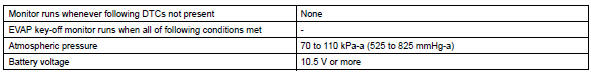

Typical enabling conditions

Typical malfunction thresholds

"Saturated" indicates that the evap pressure change is less than 0.286 Kpa-g (2.14 Mmhg-g) in 60 seconds.

Monitor result

Refer to checking monitor status (see page es-17).

Oxygen (a/f) sensor pumping current circuit

Oxygen (a/f) sensor pumping current circuit

Description

Refer to dtc p2195 (see page es-292).

Monitor description

The air-fuel ratio (a/f) sensor varies its output voltage in proportion to

the air-fuel ratio. If the a/f sensor

imp ...

Evaporative emission system switching valve control

Evaporative emission system switching valve control

Dtc summary

Hint:

The vent valve is built into the canister pump module.

Description

The description can be found in the evap (evaporative emission) system (see

page es-335).

Inspection ...

Other materials:

Installation

Install tire pressure warning antenna and receiver

Install the receiver with the bolt.

Torque: 7.5 N*m (76 kgf*cm, 66 in.*Lbf)

Connect the connector.

Install inner roof side garnish assembly

rh (see page ir-52)

Install deck trim side panel assembly rh

(w/o rear no. 2 S ...

Diagnosis system

Bus check

Select "bus check" from the "obd / mobd

menu" screen.

Hint:

The ecus and sensors that are properly connected

to the can communication system can be displayed

using the intelligent tester via can vim.

Press "enter" on the intelligen ...

Preparations to

use wireless

communication

The following can be performed using bluetoothÂź wireless communication:

A portable audio player can be operated and listened to via

audio system

Hands-free phone calls can be made via a cellular phone

In order to use wireless communication, register and connect a

bluetoothÂź device by p ...