Toyota RAV4 (XA40) 2013-2018 Service Manual: Installation (2005/11-2006/01)

- Install abs and traction actuator assembly with bracket

Notice:

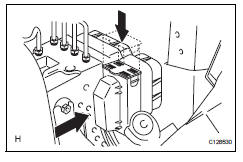

Do not remove the hole plug before connecting the brake tube. New actuators are filled with brake fluid.

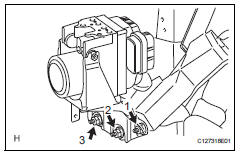

- Install the actuator with bracket with the 3 nuts.

Torque: 19 n*m (194 kgf*cm, 14 ft.*Lbf)

Hint:

The nuts should be tightened in order from 1 to 3 as shown in the illustration.

Notice:

Be careful not to damage the brake tubes.

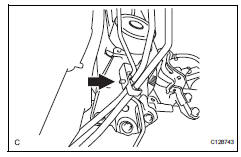

- Connect the brake tube clamp to the bracket.

- Connect the connector and push the lock lever downward.

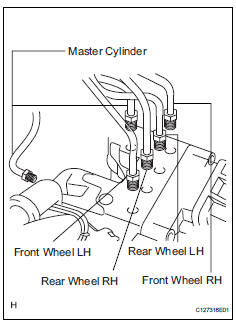

- Connect brake lines

- Using sst, connect the 6 brake lines to the correct locations on the actuator, as shown in the illustration.

Sst 09023-00101

Torque: 15.2 N*m (155 kgf*cm, 11 ft.*Lbf) without sst

14 N*m (144 kgf*cm, 10 ft.*Lbf) with sst

Hint:

Use a torque wrench with a fulcrum length of 30 cm (11.81 In.).

- Fill reservoir with brake fluid (see page br- 6)

- Bleed air from brake master cylinder (see page br-7)

- Bleed air from brake line (see page br-7)

- Bleed air from abs and traction actuator assembly (see page br-8)

- Check brake fluid level in reservoir (see page br-6)

- Check for brake fluid leakage

- Install air cleaner case sub-assembly

- Install the air cleaner case (see page em-105).

Hint:

Refer to the procedures from the installation of the air cleaner case up until the installation of the purge vsv.

- Connect cable to negative battery terminal

- Check abs and traction actuator assembly with intelligent tester

- Check the abs and traction actuator with the intelligent tester (see page bc-180).

Removal (2006/01- )

Removal (2006/01- )

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt preten ...

Front speed sensor

Front speed sensor

Components

Removal

Hint:

Use the same procedures for the lh side and rh side.

The procedures listed below are for the lh side.

Disconnect cable from negative battery

terminal

Ca ...

Other materials:

Installation

Install accelerator pedal rod

Install the accelerator pedal rod with the 2 bolts.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*Lbf)

Connect the accelerator pedal position sensor

connector.

Connect cable to negative battery terminal

...

Pressure control solenoid "A " performance (shift solenoid valve sl1)

Description

The ecm uses signals from the vehicle speed sensor to detect the actual gear

position (1st, 2nd, 3rd or

o/d gear).

Then the ecm compares the actual gear with the shift schedule in the ecm memory

to detect mechanical

problems of the shift solenoid valves, valve body or automatic ...

Lower instrument panel

Precaution

Precaution for vehicle with srs airbag and

seat belt pretensioner

Some operations in this section may affect the srs

airbags and seat belt pretensioner. Prior to

performing the corresponding operations, read the

srs airbag notice (see page rs-1).

Components

...