Toyota RAV4 (XA40) 2013-2018 Service Manual: Installation (2005/11-2006/01)

- Install front drive shaft assembly lh

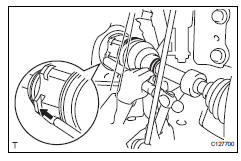

- Coat the spline of the inboard joint shaft with gear oil.

- Using a brass bar and hammer, align the shaft splines in the drive shaft.

Notice:

- Set the snap ring with the opening side facing downwards.

- Be careful not to damage the oil seal, boot and dust cover.

- Install front drive shaft assembly rh

- Coat the spline of the inboard joint shaft with gear oil.

- Align the shaft spline and install the drive shaft with 2 bolts.

Torque: 63.7 N*m (650 kgf*cm, 47 ft.*Lbf)

Notice:

Do not damage the oil seal, boot and dust cover.

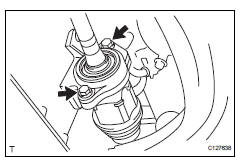

- Connect steering knuckle with axle hub lh

- Align the shaft splines in the drive shaft to the steering knuckle with axle hub.

- Connect steering knuckle with axle hub rh

Hint:

Use the same procedures described for the lh side.

- Connect front suspension no. 1 Lower arm sub-assembly lh (see page ah-10)

- Connect front suspension no. 1 Lower arm sub-assembly rh

Hint:

Use the same procedures described for the lh side.

- Install front stabilizer link assembly lh (see page sp-31)

- Install front stabilizer link assembly rh

Hint:

Use the same procedures described for the lh side.

- Connect tie rod end sub-assembly lh (see page ps-45)

- Connect tie rod end sub-assembly rh

Hint:

Use the same procedures described for the lh side.

- Connect front speed sensor lh

- Connect the speed sensor (see page bc-191).

- Connect front speed sensor rh

Hint:

Use the same procedures described for the lh side.

- Install front axle hub nut (see page ah-10)

- Install front wheel torque: 103 n*m (1,050 kgf*cm, 76 ft.*Lbf)

- Add automatic transaxle fluid

- Add automatic transaxle fluid for u140f (see page ax-152).

- Add automatic transaxle fluid for u241e (see page ax-151).

- Check for automatic transaxle oil leakage

- Inspect and adjust front wheel alignment

- Inspect and adjust the front wheel alignment (see page sp-3).

Reassembly (2006/01- )

Reassembly (2006/01- )

Install drive shaft bearing case subassembly

(for rh)

Install the bearing snap ring.

Using sst and a press, press in the drive shaft

bearing case to the inboard joint rh.

Sst 095 ...

Installation (2006/01- )

Installation (2006/01- )

Install front drive shaft assembly lh

Coat the spline of the inboard joint shaft with gear

oil.

Align the shaft splines and tap in the drive shaft with

a brass bar and hammer.

No ...

Other materials:

When towing active torque control 4wd vehicles

Use one of the methods shown below to tow the

vehicle.

If the vehicle has trouble in the chassis and drivetrain,

use method 1 (flat bed truck).

Notice:

Do not use any towing method other than those

shown above.

For example, the towing methods shown below are

dangerous or dama ...

Detailed bluetooth®

system settings

You can confirm and change the detailed bluetooth® settings.

How to check and change detailed bluetooth® settings

Display the “bluetooth* setup” screen.

Select “system settings”.

The following screen is displayed:

Bluetooth® power on/off. You can change bluetooth®

fu ...

Rear occupant classification sensor rh circuit malfunction

Description

The rear occupant classification sensor rh circuit consists of the occupant

classification ecu and the

rear occupant classification sensor rh.

Dtc b1783 is recorded when a malfunction is detected in the rear occupant

classification sensor rh

circuit.

Wiring diagram

...