Toyota RAV4 (XA40) 2013-2018 Service Manual: Receiver error

![]()

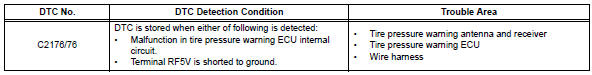

Description

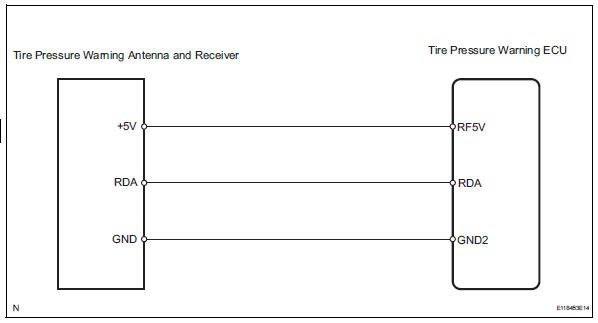

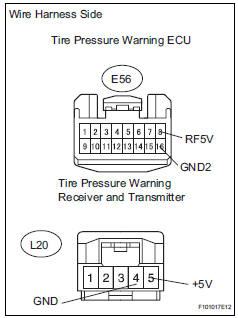

Wiring diagram

Inspection procedure

Notice:

It is necessary to register an id code after replacing the tire pressure warning valve abd transmitter and/or the tire pressure warning ecu (see page tw-9).

Hint:

Set the tire pressure to the specified value.

Standard pressure: 220 kpa (2.2 Kgf/cm2, 32 psi)

- Check tire pressure warning ecu

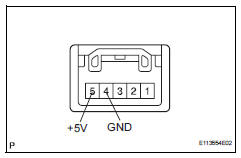

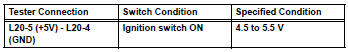

- Measure the voltage of the connector.

Standard voltage

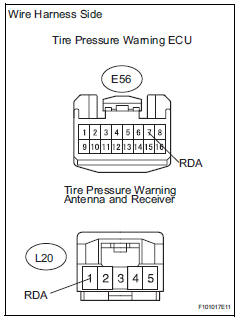

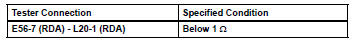

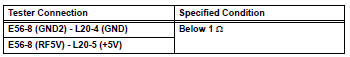

- Check wire harness (ecu - receiver)

- Disconnect the e56 ecu connector.

- Disconnect the l20 receiver connector.

- Measure the resistance of the wire harness side connectors.

Standard resistance

- Replace tire pressure warning antenna and receiver

- Check dtc

- Check for dtc (see page tw-20).

Ok: dtc is not output.

Hint:

- It is necessary to register an id when replacing the tire pressure warning ecu (see page tw-9).

- Read id on the data list before removing the tire pressure warning ecu. Register the id in the new tire pressure warning ecu.

End

- Check wire harness (ecu - receiver)

- Disconnect the e56 ecu connector.

- Disconnect the l22 receiver connector.

- Measure the resistance of the wire harness side connectors.

Standard resistance

Replace tire pressure warning ecu

Transmitter id not registered in main mode

Transmitter id not registered in main mode

Description

Inspection procedure

Notice:

It is necessary to register an id code after replacing the tire pressure

warning valve and

transmitter and/or the tire pressure monitor ecu (see ...

Vehicle speed signal error (test mode dtc)

Vehicle speed signal error (test mode dtc)

Description

The tire pressure warning ecu receives a speed signal from the combination

meter. This dtc is stored

upon entering test mode, and cleared when a vehicle speed signal of 12 mph (20 ...

Other materials:

Check mode procedure

Hint:

Intelligent tester only:

compared to normal mode, check mode is more sensitive to

malfunctions. Therefore, check mode can detect the

malfunctions that cannot be detected by normal mode.

Notice:

All the stored dtcs and freeze frame data are erased if:

The ecm is changed from normal mo ...

Side airbag sensor

Components

On-vehicle inspection

Check side airbag sensor (vehicle not

involved in collision)

Perform a diagnostic system check (see page rs-

49).

Check side airbag sensor (vehicle involved

in collision and airbag has not deployed)

Perform a diagnostic system check ( ...

Lost communication with front passenger side - side airbag sensor assembly

Description

The side airbag sensor rh consists of parts including the diagnostic circuit

and the lateral deceleration

sensor.

When the center airbag sensor receives signals from the lateral deceleration

sensor, it determines

whether or not the srs should be activated.

Dtc b1627/82 i ...